A kind of preparation method of flame retardant waterproof adhesive for corrugated carton

A corrugated box and waterproof adhesive technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of shortening the service life and protection performance of corrugated boxes, reducing the safety performance of corrugated boxes, and easy moisture absorption of adhesives, etc. , achieve the effect of saving dosage, strong viscosity and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

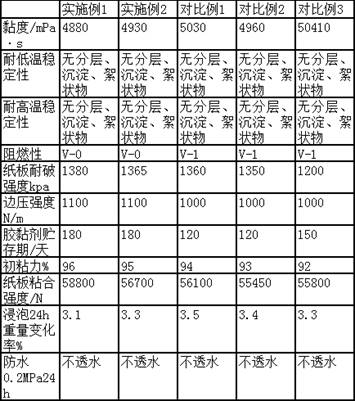

Examples

Embodiment 1

[0019] A method for preparing a flame-retardant waterproof adhesive for corrugated cartons, specifically comprising the following steps:

[0020] (1) 63 parts of hexamethylcyclotrisiloxane in a homogeneous stirrer, at a stirring speed of 1000r / min, slowly drop 55 parts of an aqueous solution of sodium lignosulfonate with a mass fraction of 10%, and increase the stirring speed to 5000r / min, continue to stir for 15min, add 101 parts of water to dilute, and then use a homogenizer to pass it twice under the pressure of 1000Pa to obtain an emulsion with an average particle size of 250mm, and place it at room temperature for 15h for polymerization. Neutralize 10% sodium carbonate aqueous solution to a pH value of 8 to obtain a white emulsion A, then add 4 parts of dodecylbenzenesulfonic acid and 670 parts of water to another reaction kettle, and heat to 55°C under stirring. Slowly add a mixture of 110 parts of hexamethyldisiloxane and 150 parts of polymethylsilicate within 2 hours. ...

Embodiment 2

[0028]A method for preparing a flame-retardant waterproof adhesive for corrugated cartons, specifically comprising the following steps:

[0029] (1) 50 parts of hexamethylcyclotrisiloxane in a homogeneous stirrer, at a stirring speed of 1000r / min, slowly drop 55 parts of an aqueous solution of sodium lignosulfonate with a mass fraction of 10%, and increase the stirring speed to 5000r / min, continue to stir for 15min, add 101 parts of water to dilute, and then use a homogenizer to pass twice under the pressure of 1200Pa to obtain an emulsion with an average particle size of 250mm, and place it at room temperature for 15h for polymerization. Neutralize 10% sodium carbonate aqueous solution to pH 8 to obtain white emulsion A, then add 5 parts of dodecylbenzenesulfonic acid and 670 parts of water into another reaction kettle, and heat to 55°C under stirring. Slowly add a mixture of 110 parts of hexamethyldisiloxane and 150 parts of polymethylsilicate within 2 hours. After the drop,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com