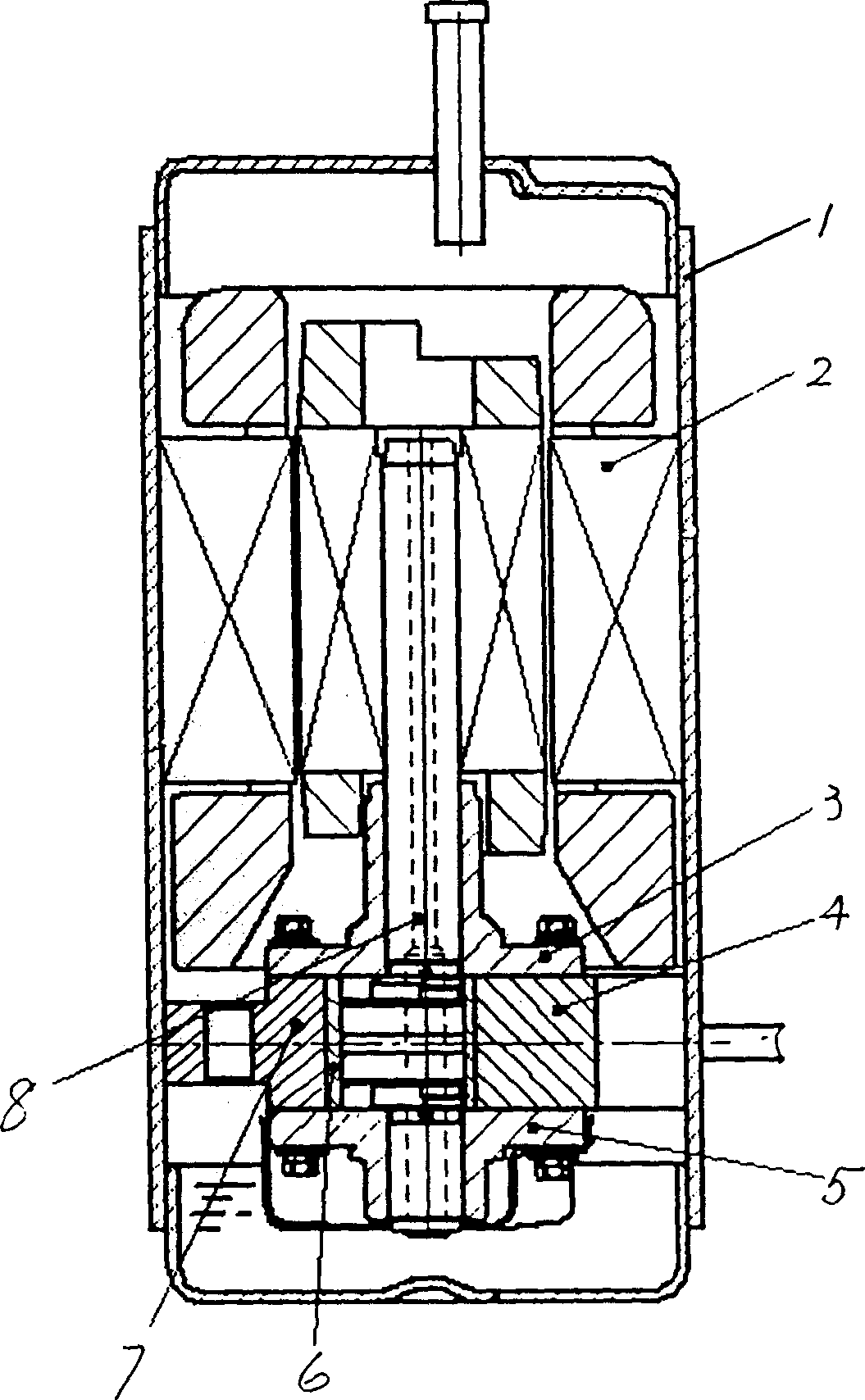

Integral piston with embedded blades and its manufacture

A mosaic and piston technology, which is applied in the direction of rotary piston pumps, rotary piston machines, liquid fuel engines, etc., can solve the problems of difficult processing of piston 6, high processing cost, and high scrap rate, so as to improve the processing technology and reduce the Effects of Manufacturing Tooling Costs and Scrap Rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

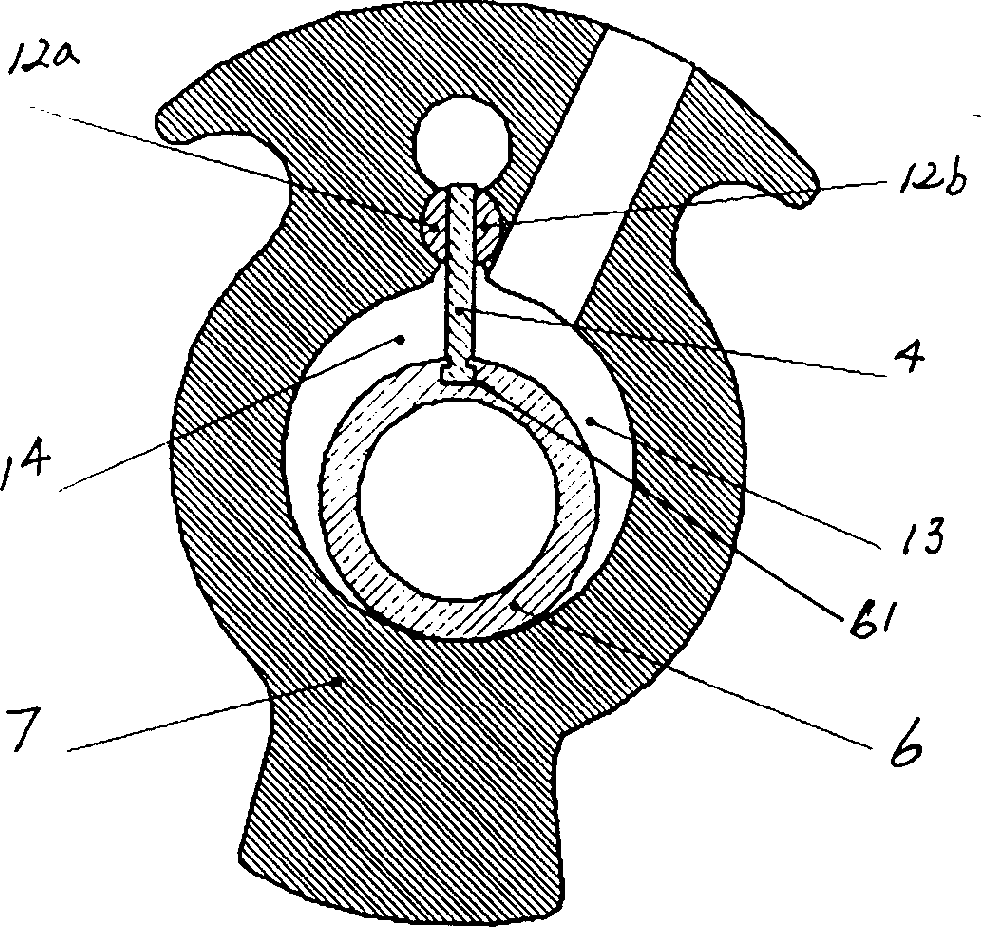

Embodiment 1

[0016] There is a T-shaped through groove 61 on one side of the piston 6, the shape of the tail of the vane 4 matches the T-shaped groove on the piston 6, and an interference fit is adopted at the matching part, such as figure 2 shown.

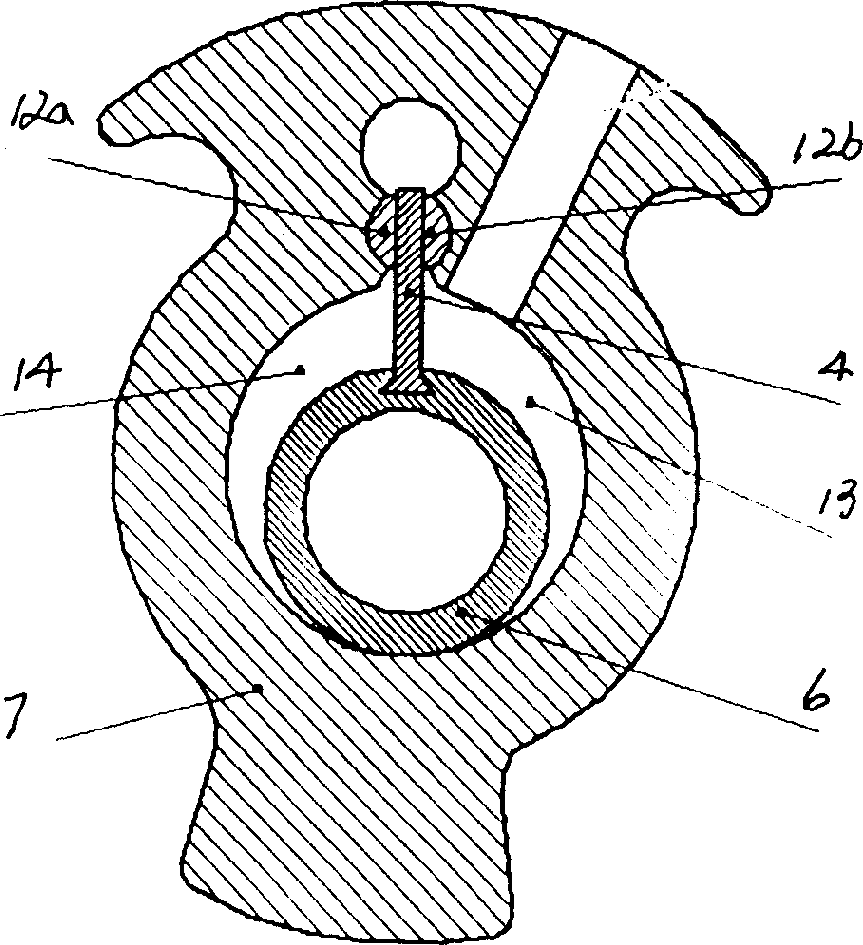

Embodiment 2

[0018] The interference fit structure of the dovetail groove is adopted at the matching part of the piston 6 and the vane 4, such as image 3 shown.

Embodiment 3

[0020] The matching parts of the piston 6 and the vane 4 adopt the interference fit structure of the large circular hole groove, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com