Equipment and method for producing photo film

A technology for manufacturing equipment and manufacturing methods, which is applied in the packaging, transportation and packaging of films, camera bodies, etc., and can solve the problems of not adopting the idea of mobility and having a small degree of freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

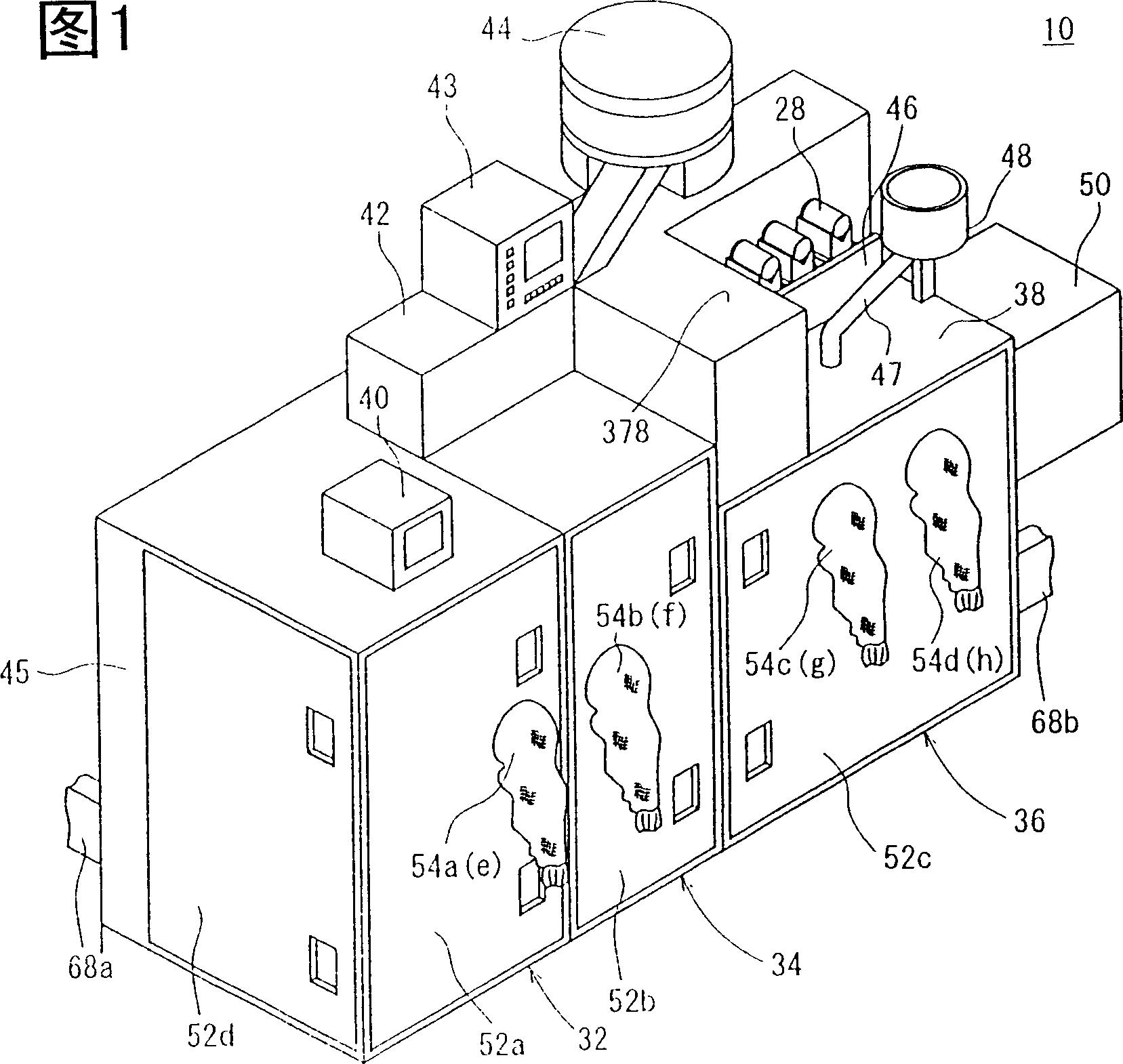

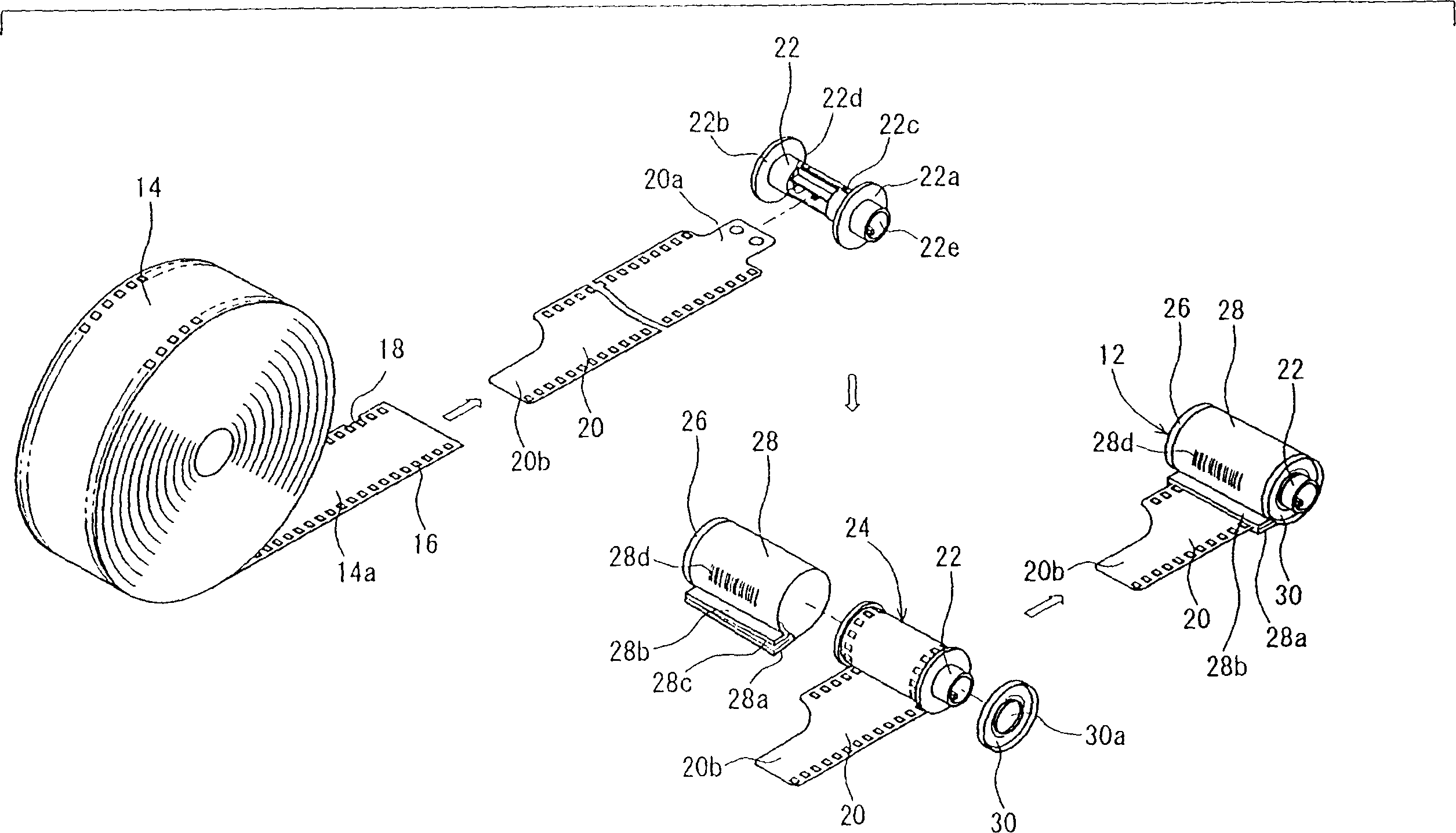

[0109] FIG. 1 is a perspective view of a film manufacturing apparatus 10 according to a first embodiment of the present invention. The film manufacturing equipment 10 is used to manufacture figure 2 The film loading cassette 12 is shown. like figure 2 As shown, an unexposed film web 14 carries a latent image as a side positive and has perforations 16 formed one after the other on opposite sides thereof and cutouts 18 formed at predetermined intervals on one longitudinal edge thereof, Each of the predetermined intervals is set to a given length according to the film size (film length), respectively. The film strip 14a unwound from the film roll 14 is cut to a prescribed length to form a cut-to-length film 20 which is then wound onto a spool 22 to form a roll assembly 24 . Afterwards, the roll film assembly 24 is inserted into the cassette 28 with one side open, the cover 26 is mounted on one end of the cassette, and the cover 30 is mounted on the other end of the cassette, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com