Prepn process of paraffin hydrofining catalyst

A technology for hydrorefining and catalyst, applied in the refining of petroleum wax, etc., can solve the problems of easy crushing, poor thermal stability, unable to meet product quality requirements, etc., and achieve the effect of improving the activity and improving the activity of the catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

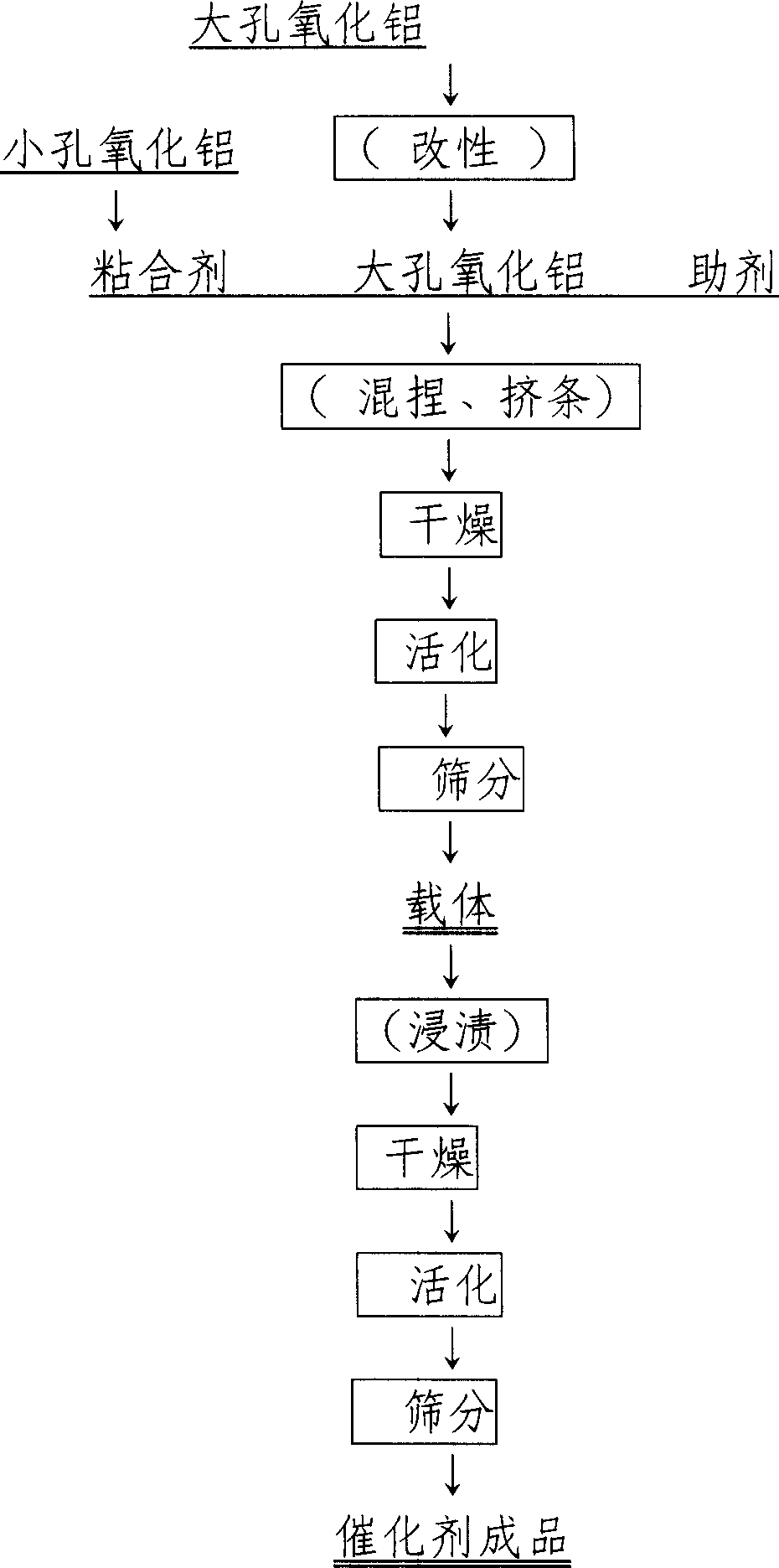

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation

[0022] (1) Determination of the load of active components

[0023] The activity of the hydrotreating catalyst is closely related to the content of its active components. Within a certain range, the higher the active component, the better the activity of the catalyst, but its manufacturing cost also increases. Therefore, we prepared several catalysts with different metal contents for evaluation, and the evaluation results are shown in Table 3. The results show that the metal content value is MoO 3 15.5%, NiO 4.5%.

[0024] Catalyst number

B-1

B-2

B-3

B-4

metal content

MoO 3 %

NiO%

13.08

3.55

14.12

4.36

15.27

4.52

18.64

6.71

Create wax shades

25

28

30

30

[0025] operating conditions

Alumina Pore Size Distribution

water / oxygen

Aluminum

acid / oxygen

Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com