Vacuum cleaner having suction fan

A technology for vacuum cleaners and suction fans, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc. It can solve problems such as the impact of dust collection performance, increased gas flow resistance, and increased flow resistance, so as to improve dust collection performance and suppress forced Effect of heating and promoting cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

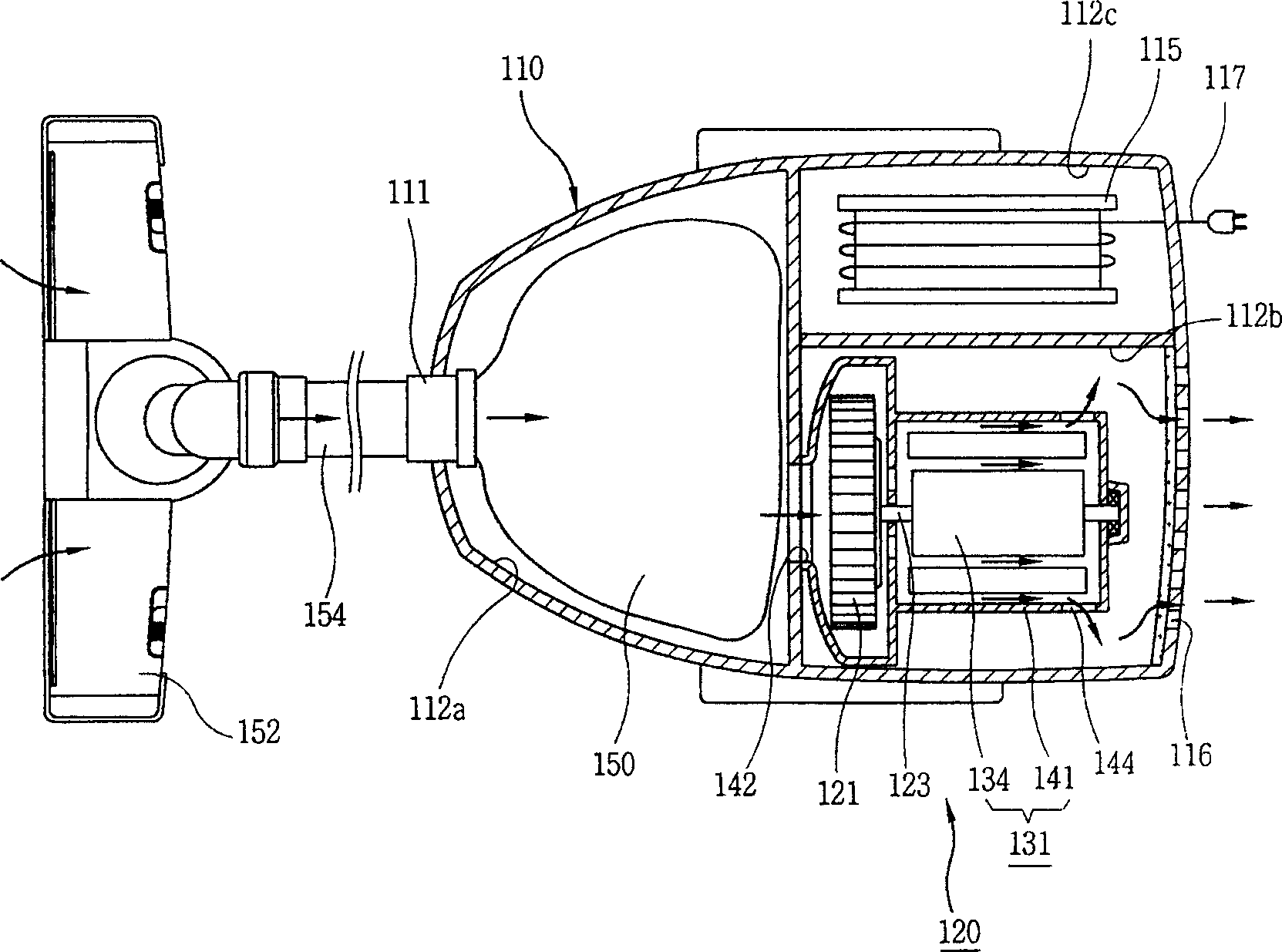

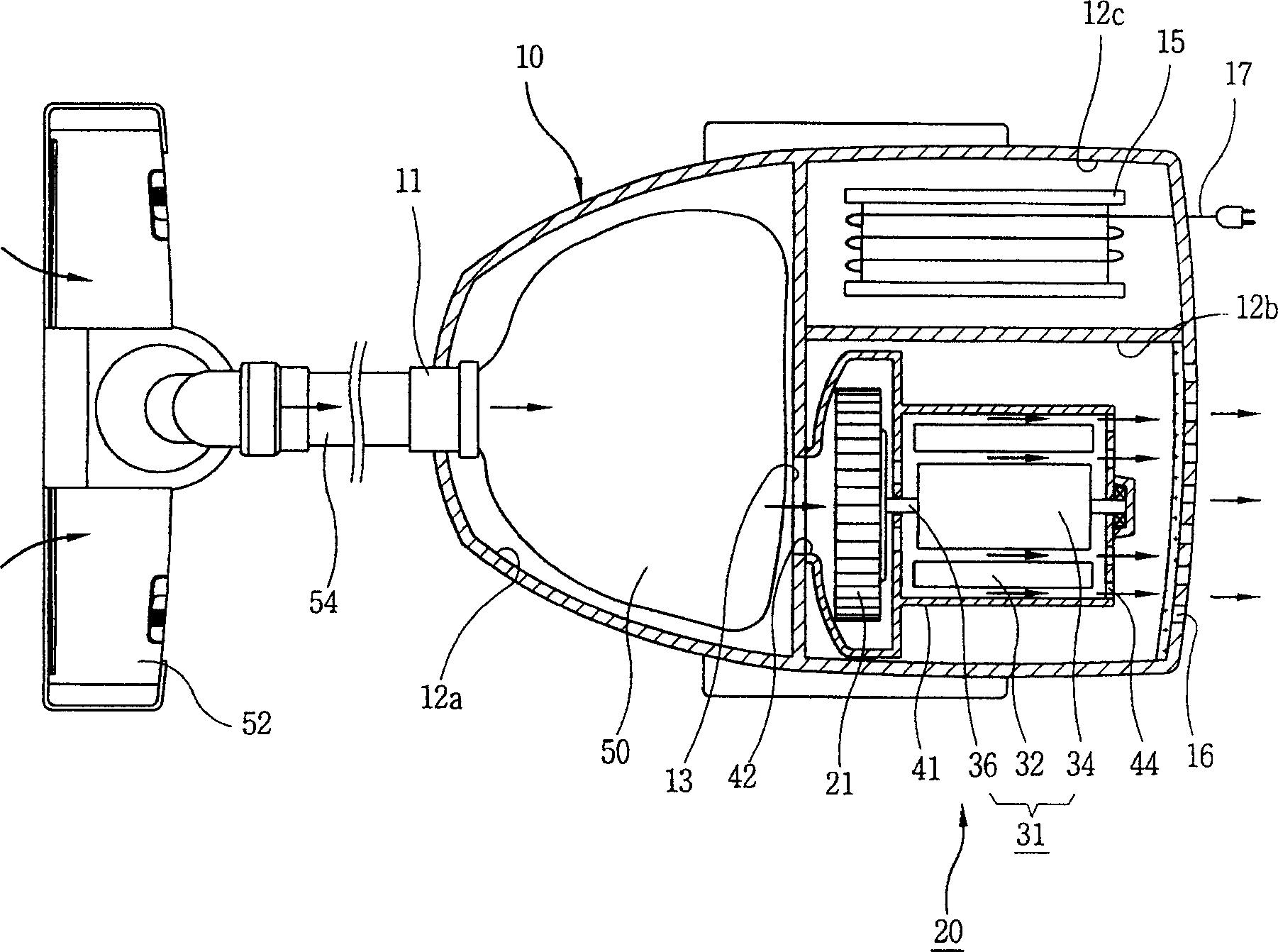

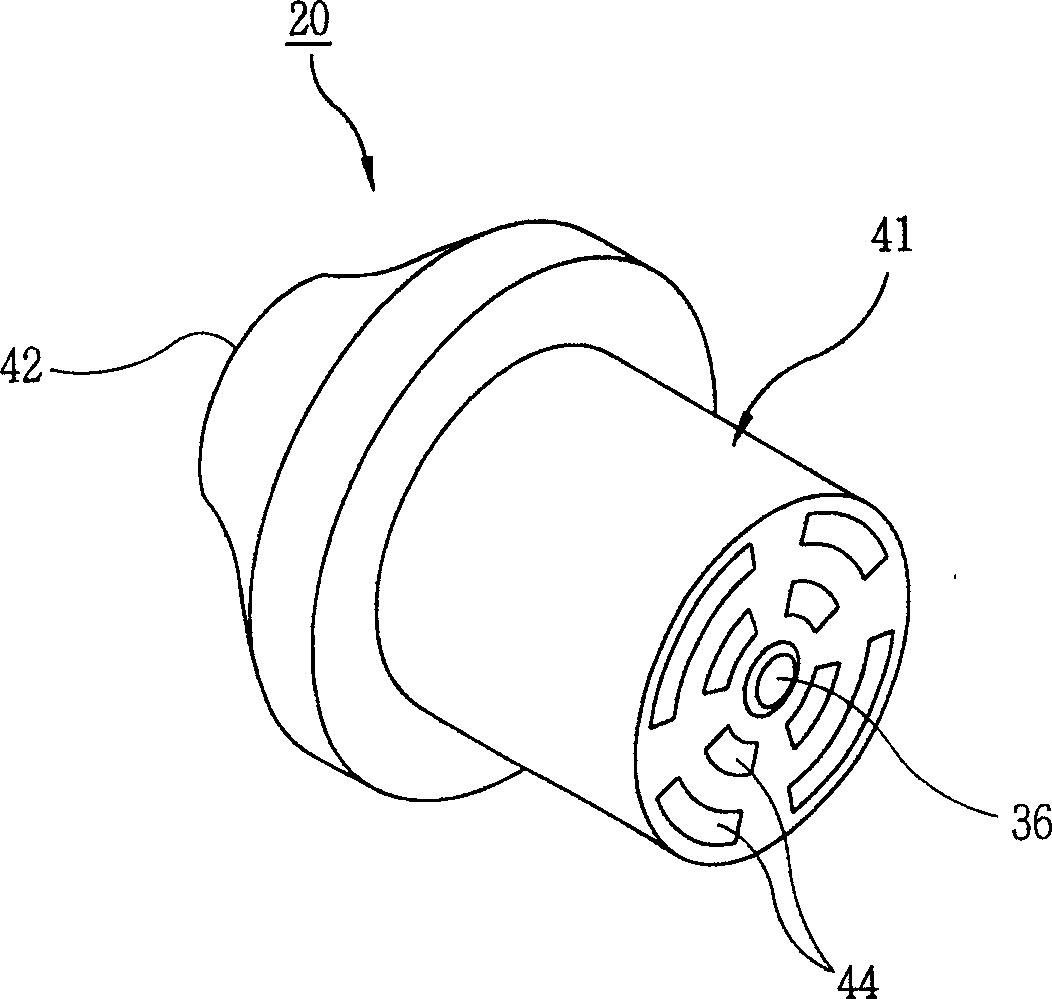

[0015] Such as figure 2 , 3 , 4, the vacuum cleaner of the present invention has the following structure: the interior of the housing 10 forms a storage space, and the rear end forms a discharge port 44; Air port 44, make exhaust port 44 correspond to discharge port 16 along the extension line of the flow direction of gas, suction fan 20 is put into the inside of shell 10, produces suction; The front of 20 is provided with a dust bag 50 that collects foreign matter such as dust in the gas; the connecting pipe 54 is connected to one side of the housing 10; the suction head 52 communicates with one end of the connecting pipe 54 to suck gas and foreign matter from the outside.

[0016] One side of the casing 10 has an interface 11 for connecting the connecting pipe 54; the other side of the interface 11 has a dust bag placement space 12a for put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com