Preparation method of organic electro luminous material 8-hydroxy quinoline aluminium

An electroluminescent material, the technology of aluminum hydroxyquinoline, applied in the direction of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of backward technology, backward production, high luminous rate, etc., and achieve simple process flow and easy equipment , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0074] The present invention will be further described below in conjunction with accompanying drawing:

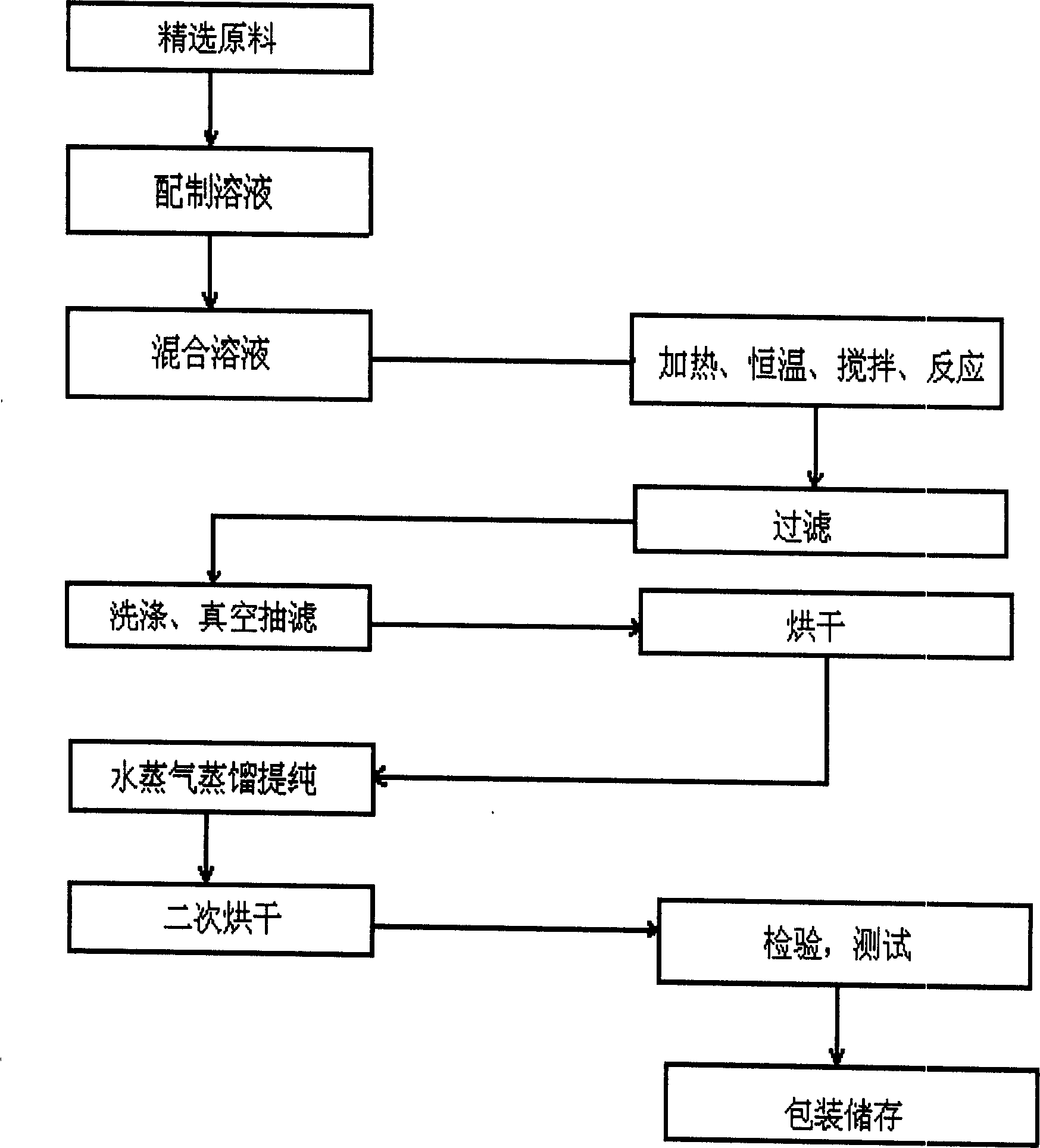

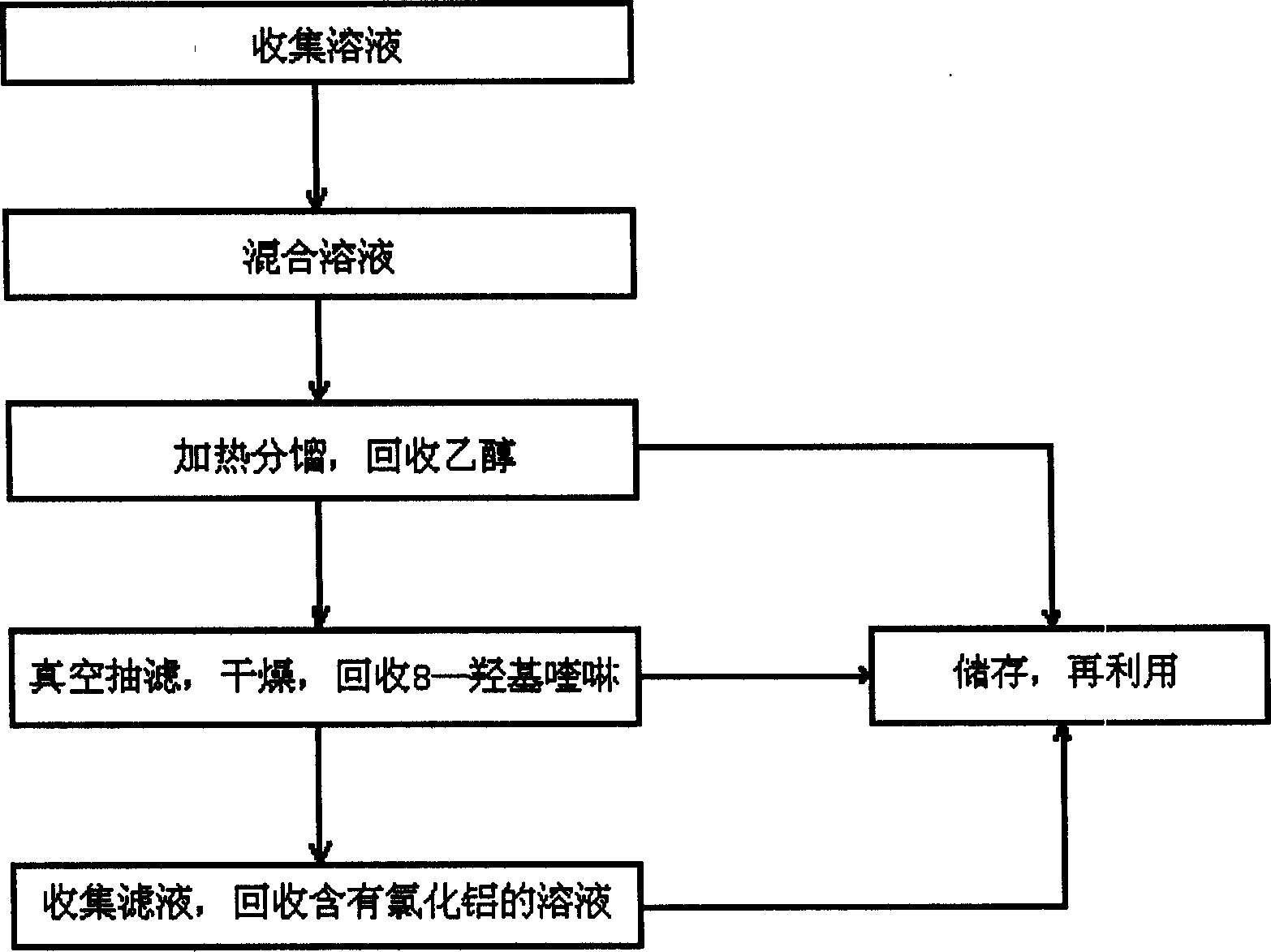

[0075] figure 1 , 3 , 4, 5, and 6, the preparation process steps of 8-hydroxyquinoline aluminum are as follows:

[0076] Compound reaction—product washing—drying—distillation purification—drying.

[0077] chemical reaction:

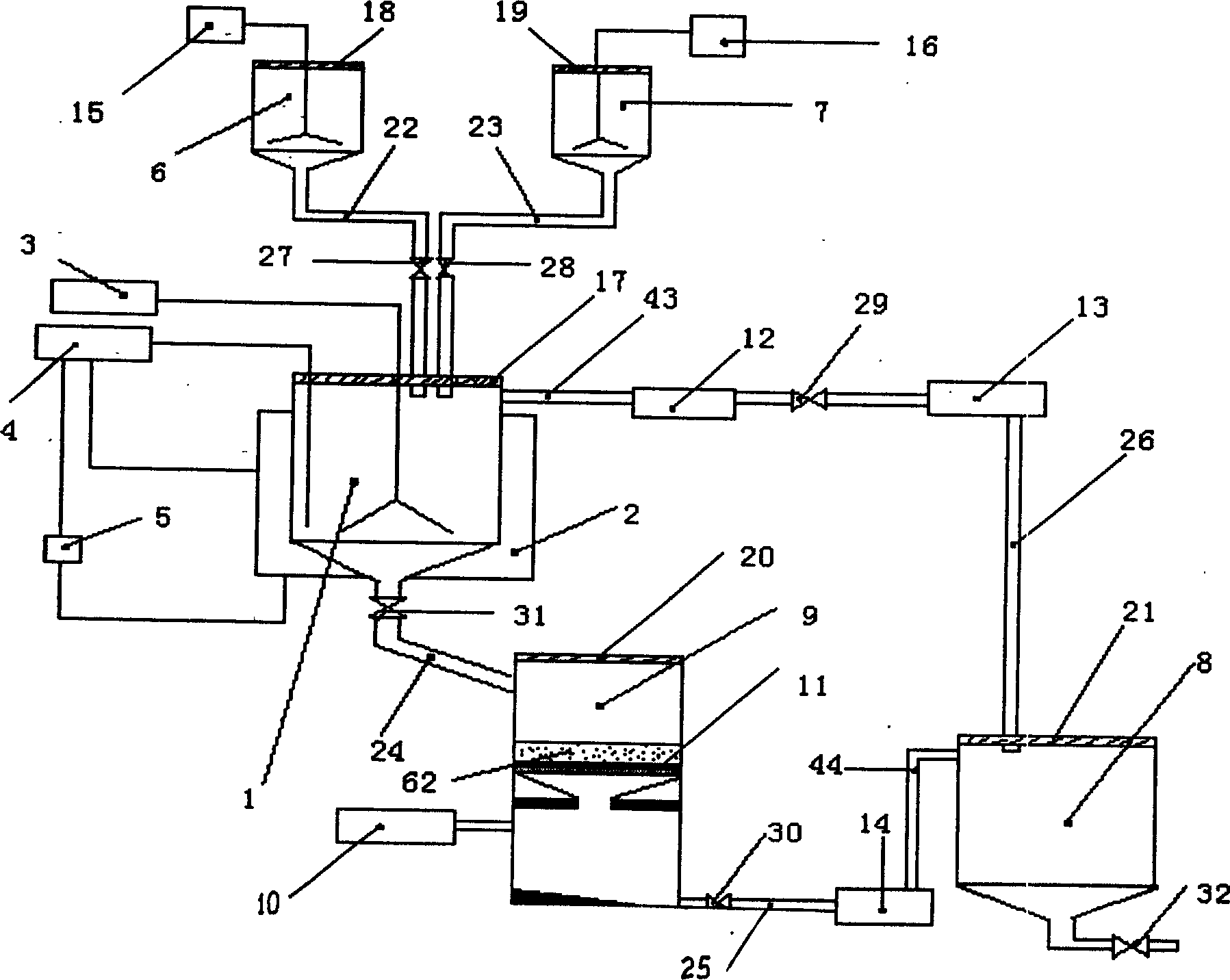

[0078] Before the reaction, the stop valves 27, 28, 29, 30, 31, and 32 are closed, and they are in the quasi-working state before the preparation.

[0079] Prepare aluminum chloride distilled aqueous solution in container 6, close with cover plate 18, stir with agitator 15 evenly.

[0080] Prepare the 8-hydroxyquinoline ethanol solution in the container 7, close it with a cover plate 19, and stir it evenly with the stirrer 16.

[0081] Open stop valve 27,28, inject two kinds of solutions in reaction vessel 1 simultaneously by pipeline 22,23, seal with cover plate 17, stir the mixed solution with agitator 3, control reaction vessel 1 temperature wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap