Method for embedding fastening piece to seat cushion

A technology for fasteners and fastening elements, applied in the field of foamed products, can solve problems such as damage to hook elements or loop elements, failure of hook and loop fasteners to be used for a long time, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

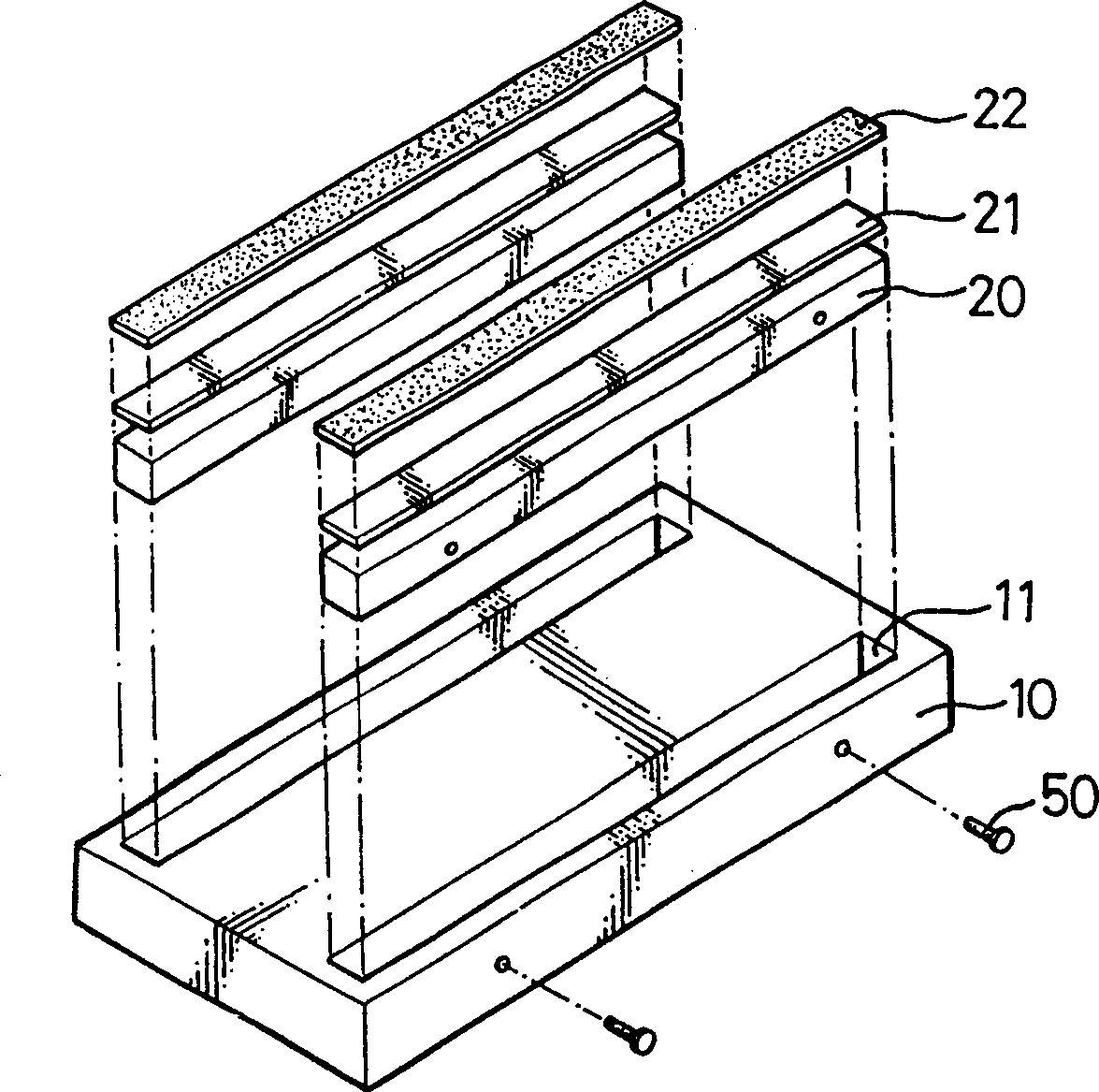

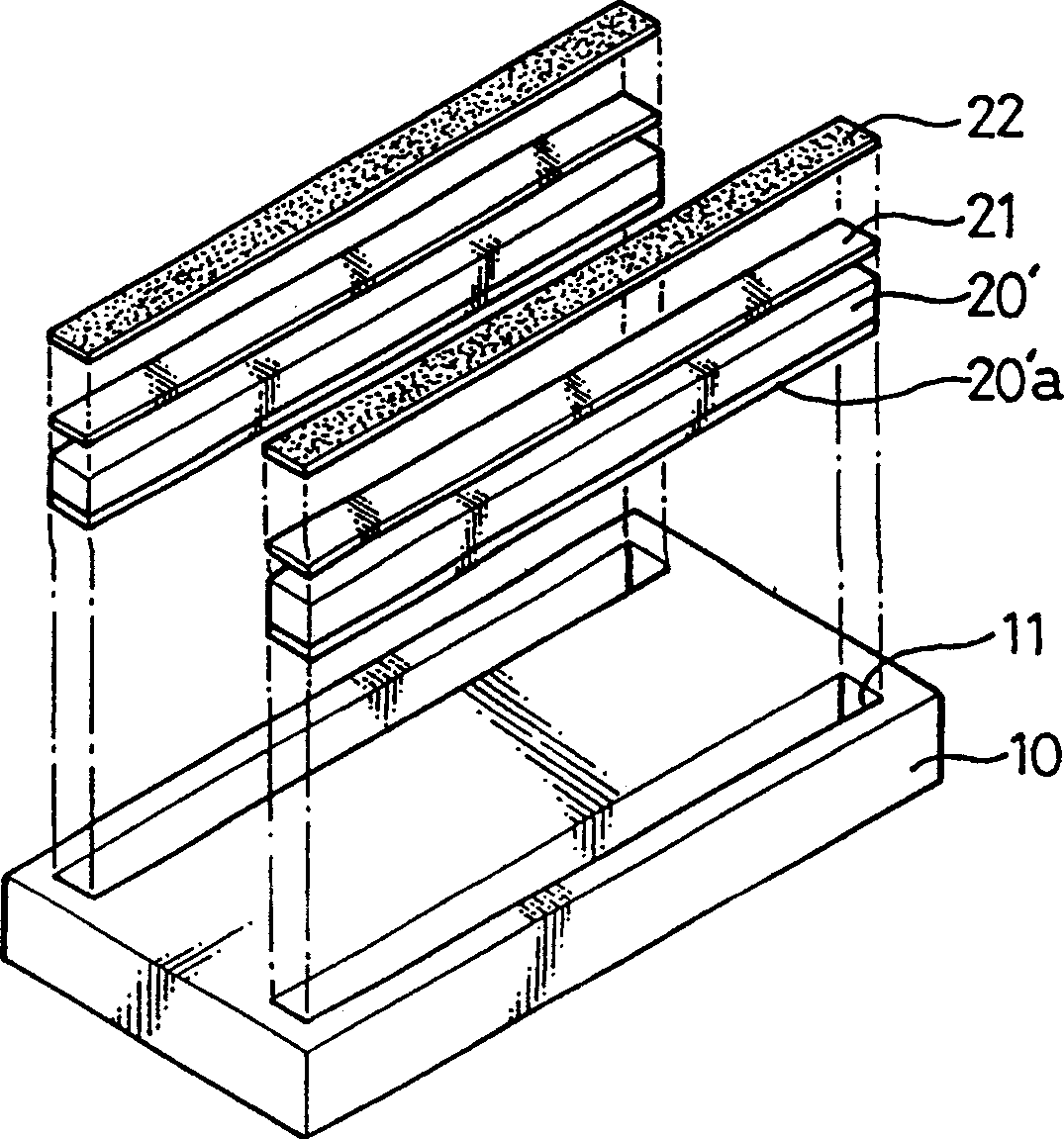

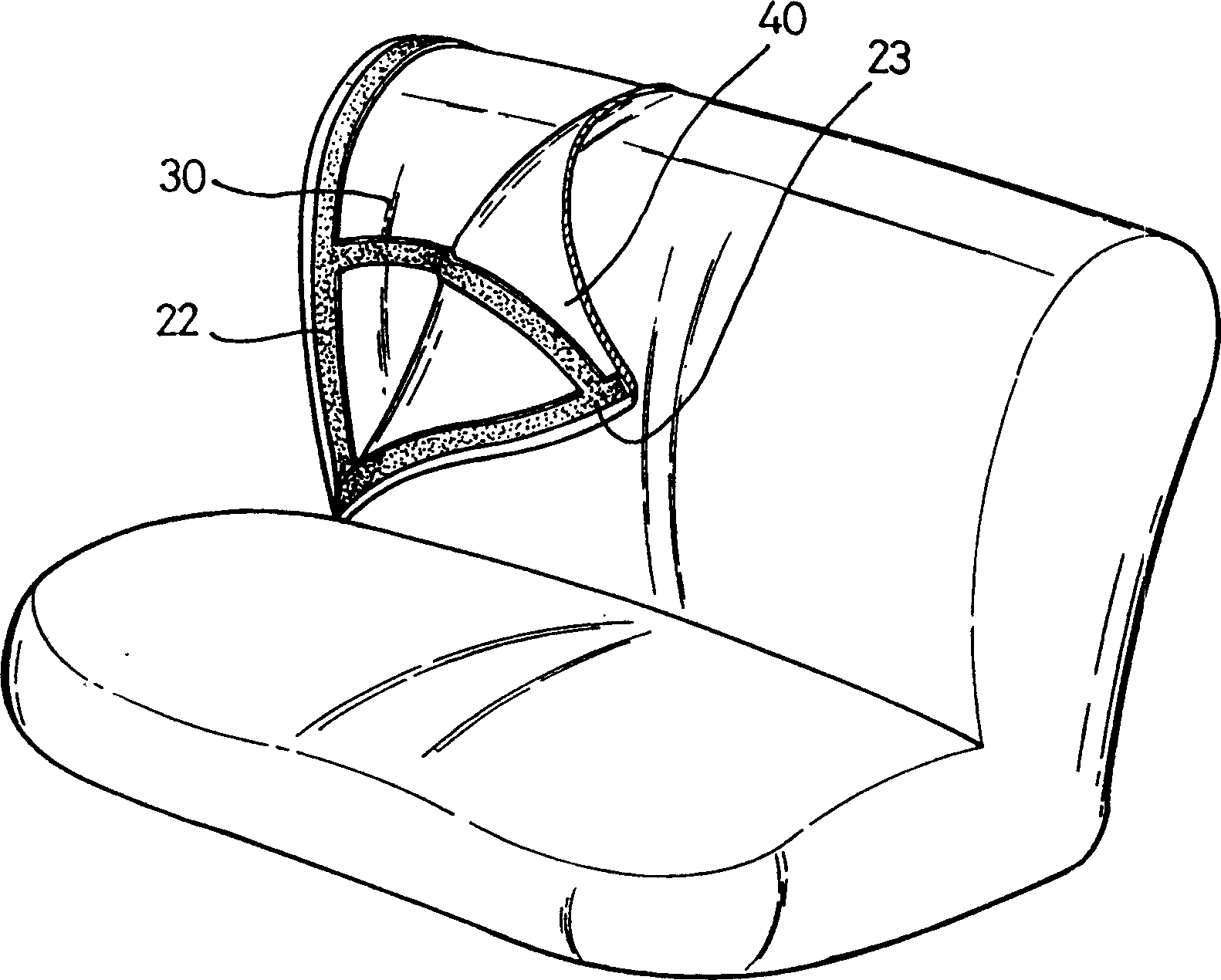

[0011] As shown in the figures, the same reference numerals represent the same or similar components in different drawings.

[0012] The process of embedding the fasteners into the seat cushion will be described in detail below.

[0013] Both the hook element and the loop element together form a complete Velcro fastener, the hook element or the loop element is fixed on the predetermined position of the metal mold, and the hook element or the loop element of the fastener is exposed outer. Then, a part of the fastening plate is connected with the fastener mounted on the metal mold, the other part of the fastening plate is exposed to the foam material to be injected, and the side of the fastening plate is provided with a fastener mounted on the metal mold. Hook or loop elements that engage fastener elements. Thereafter, the metal mold is heated to a desired temperature, and foamed material is injected into the metal mold to form a foamed product. Finally, the foamed product is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com