Cooling fan for microwave oven

A technology for cooling fans, microwave ovens, applied in microwave heating, applications, components of pumping devices for elastic fluids, etc., can solve problems such as increased noise level, large suction noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail, an example of which is shown in the accompanying drawings. In all the drawings and descriptions, the same parts use the same reference numerals.

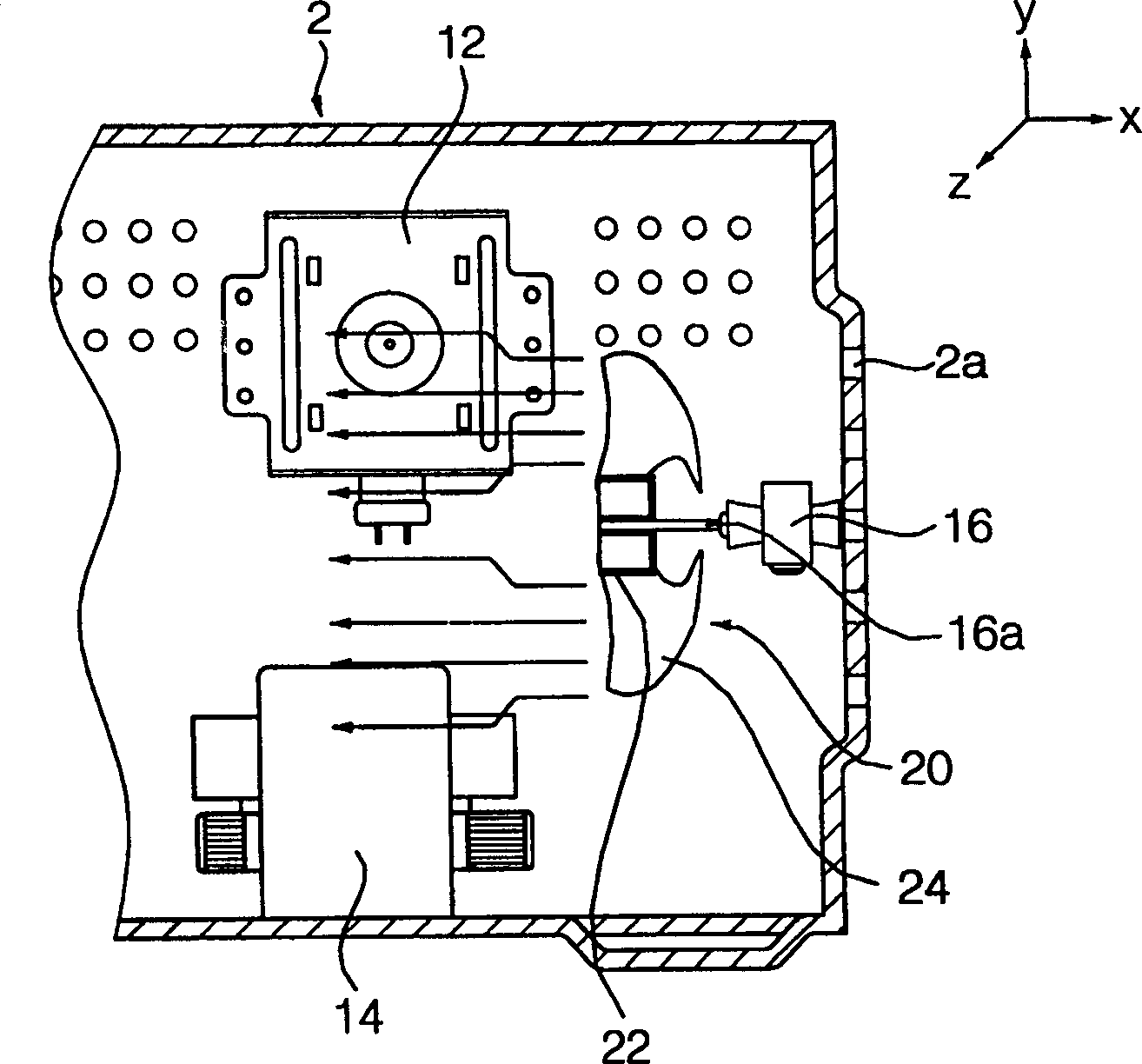

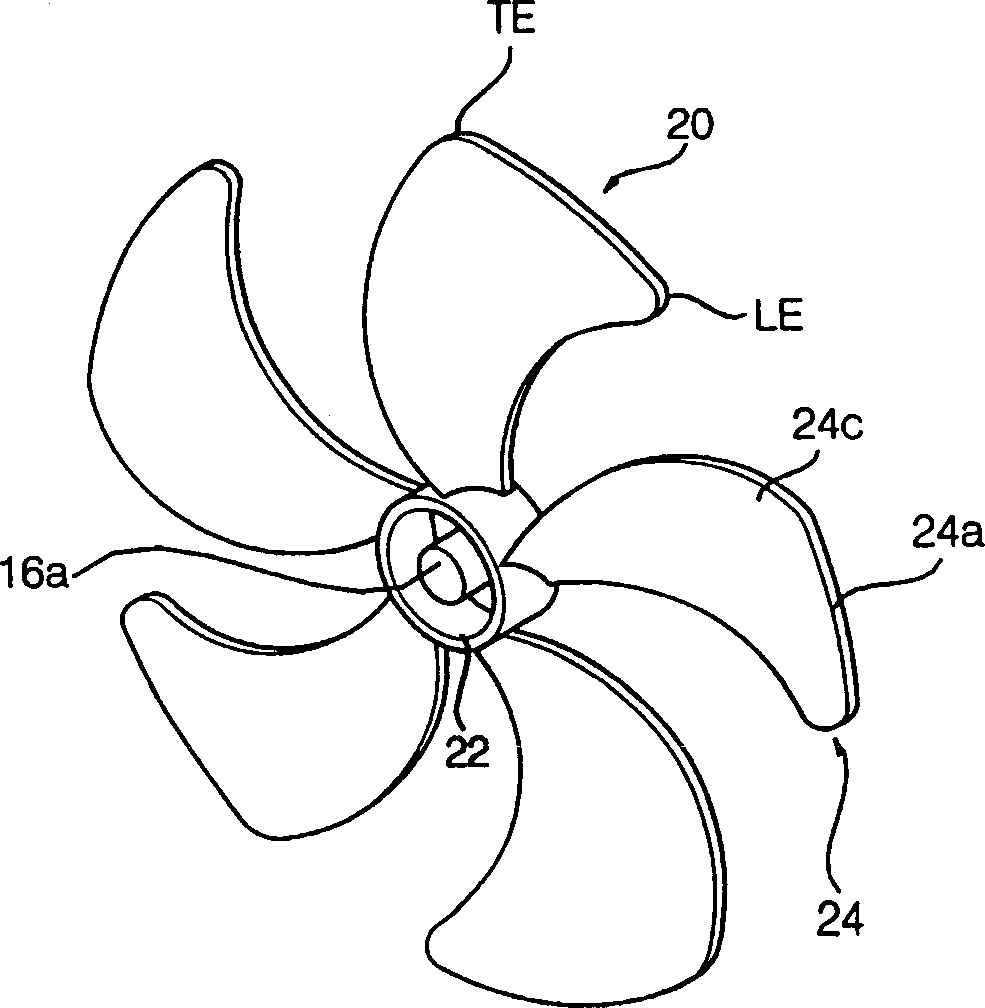

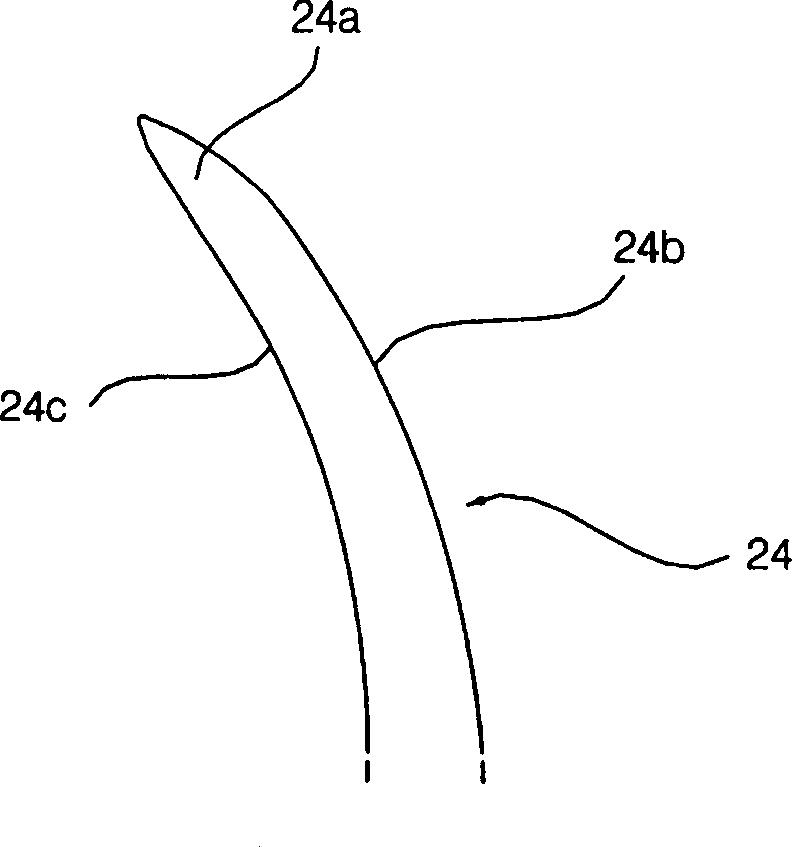

[0033] Figure 4 Is a side sectional view showing a state in which a cooling fan according to the first embodiment of the present invention is installed in the electrical equipment room of a microwave oven; Figure 5 It is a perspective view separately illustrating the cooling fan according to the first embodiment of the present invention.

[0034] Such as Figure 4 As shown, in the electrical equipment room of the microwave oven, a magnetron 62 that emits high-frequency waves into a cooking chamber (not shown in the figure) formed in the furnace 52 is provided above, and a magnetron 62 is provided below to supply high-voltage electricity to the above The high voltage transformer 64 of the magnetron 62. A mixed flow fan 70 is arranged behind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com