Design method for folded-edge blade structure of inlet end of impeller of middle and high specific rotation speed centrifugal pump

A centrifugal pump impeller and blade structure technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, and can solve the problems of corrosion damage, noise, and the system cannot operate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

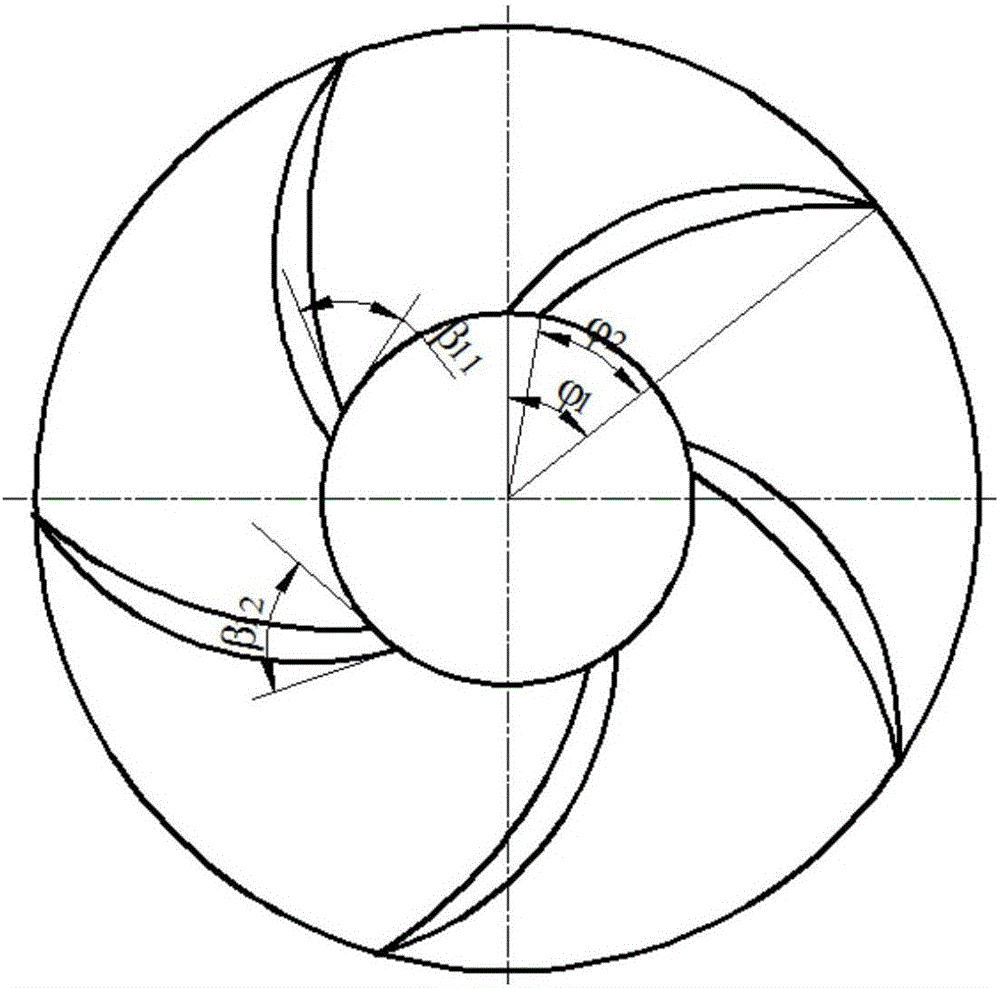

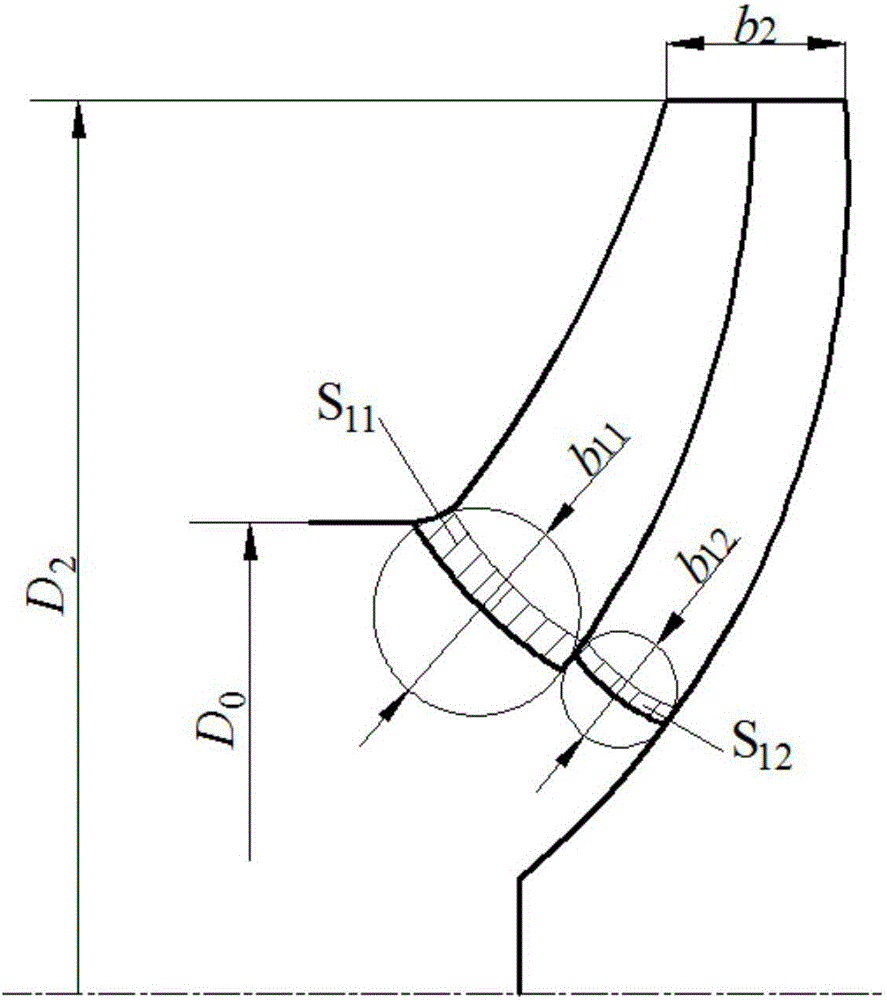

[0086] Design requirements: the flow rate under design conditions is 0.096764 cubic meters per second, the head under design conditions is 60 meters, the speed is 2900 revolutions per second, g is 10 meters per square meter, and the number of blades is 4 pieces.

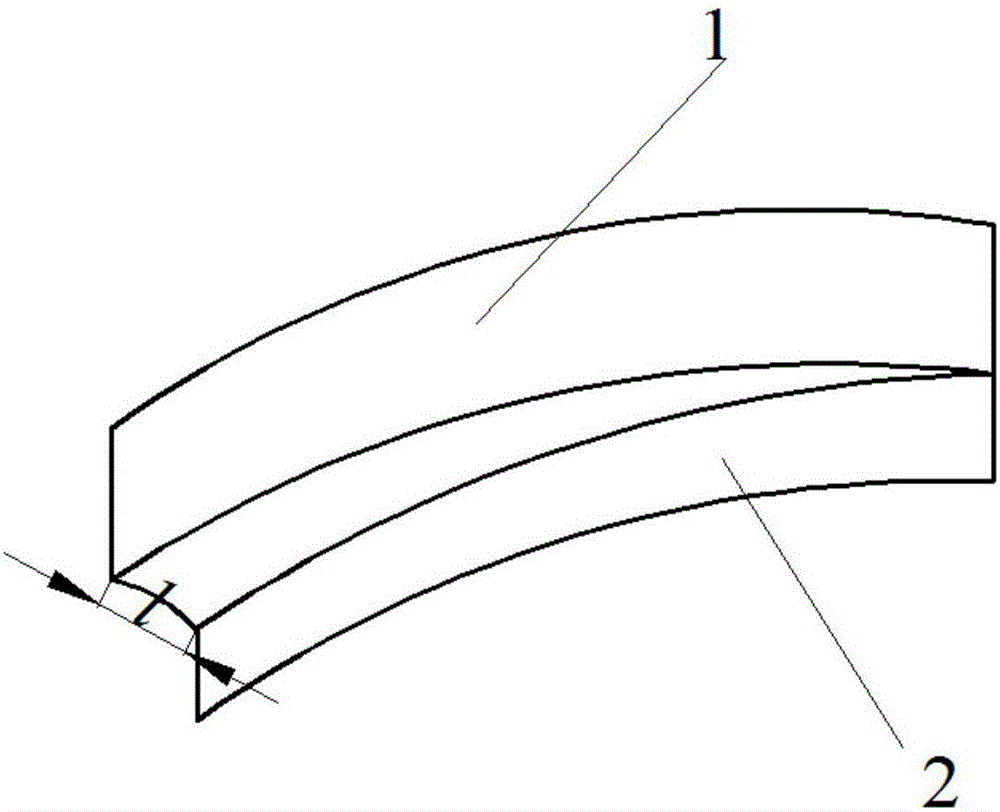

[0087] According to the above data, the value of the impeller structure parameters can be obtained: D 0 =170mm; D 2 = 390mm; β 11 = 17°; β 12 = 18°; b 11 = 11 mm; b 12 = 8mm; S 11 = 6mm; S 12 = 5mm;

[0088] In the design process, the selection of other coefficients needs to be selected according to the actual situation. For example, the parameters of the volute of the impeller need to be selected according to the actual operation of the pump.

[0089] The above is a specific description of the present invention with reference to the embodiments, but the present invention is not limited to the above embodiments, and also includes other embodiments or modified examples within the scope of the concept of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com