Traction system of bending machine with two rollers

A trigger and pull technology, applied in the field of large-scale bending equipment, can solve the problems of not being able to bend a full circle, huge volume, and unsatisfactory, and achieve the effect of a smooth process and no jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The traction system of the three-roller bending machine, taking the 80×3500 three-roller bending machine as an example, includes a pulling-out mechanism, a supporting mechanism, a wedge iron wedge mechanism, and an electrical control part.

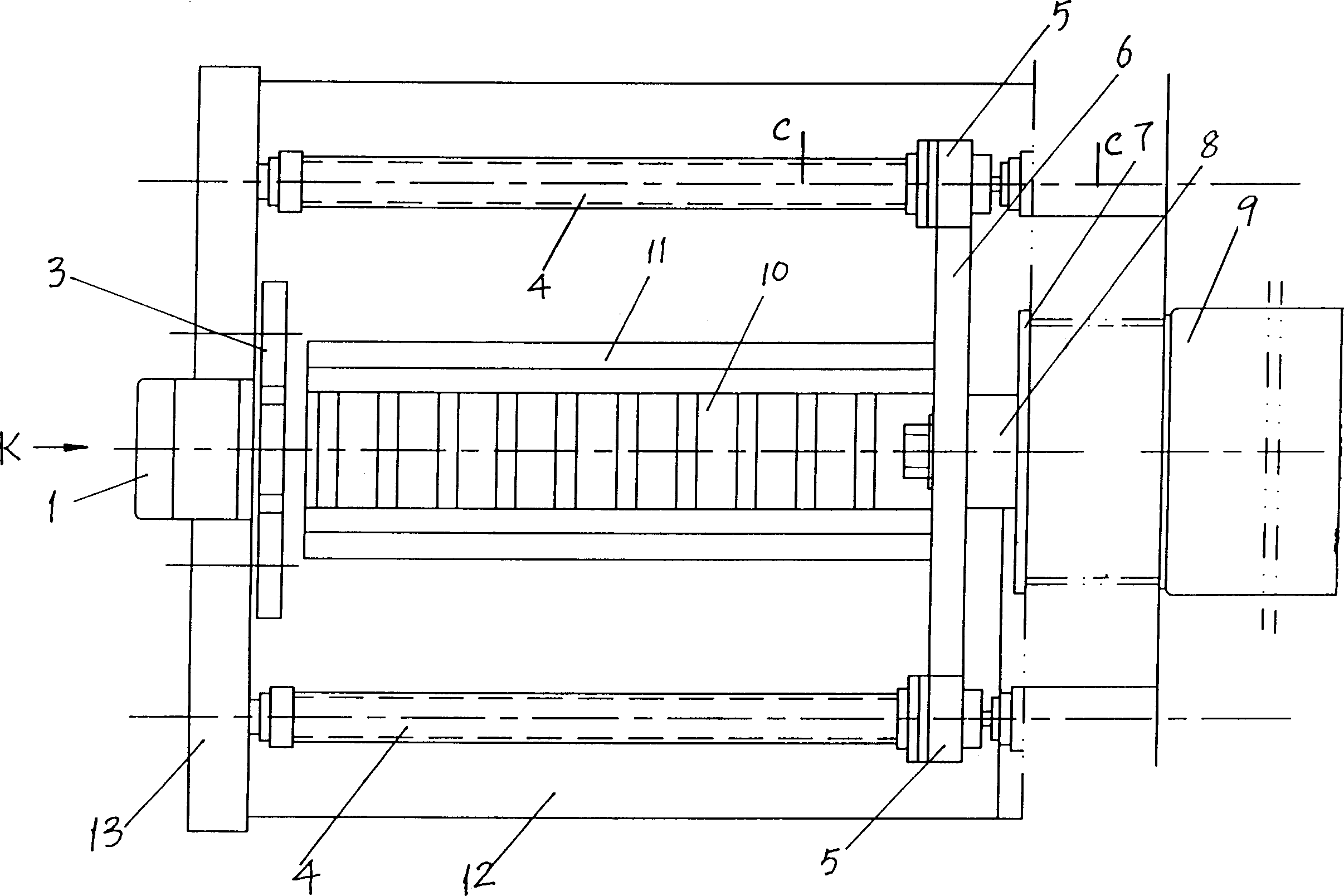

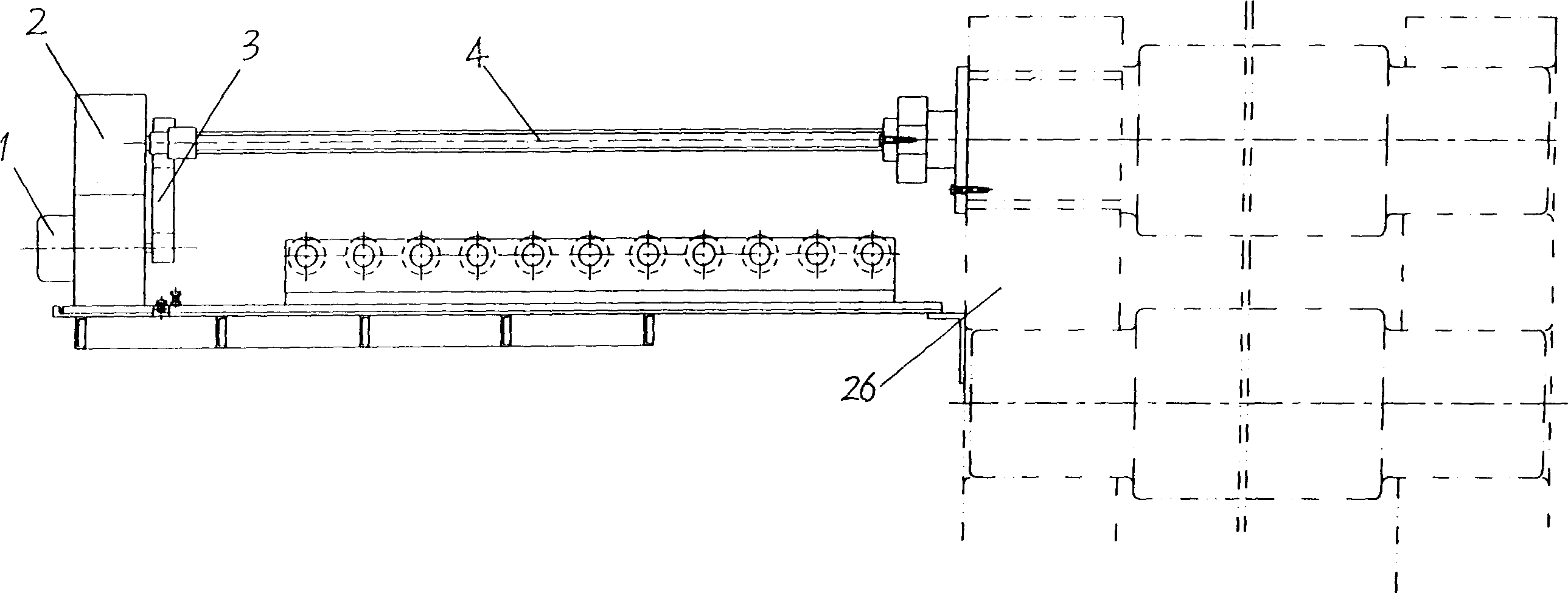

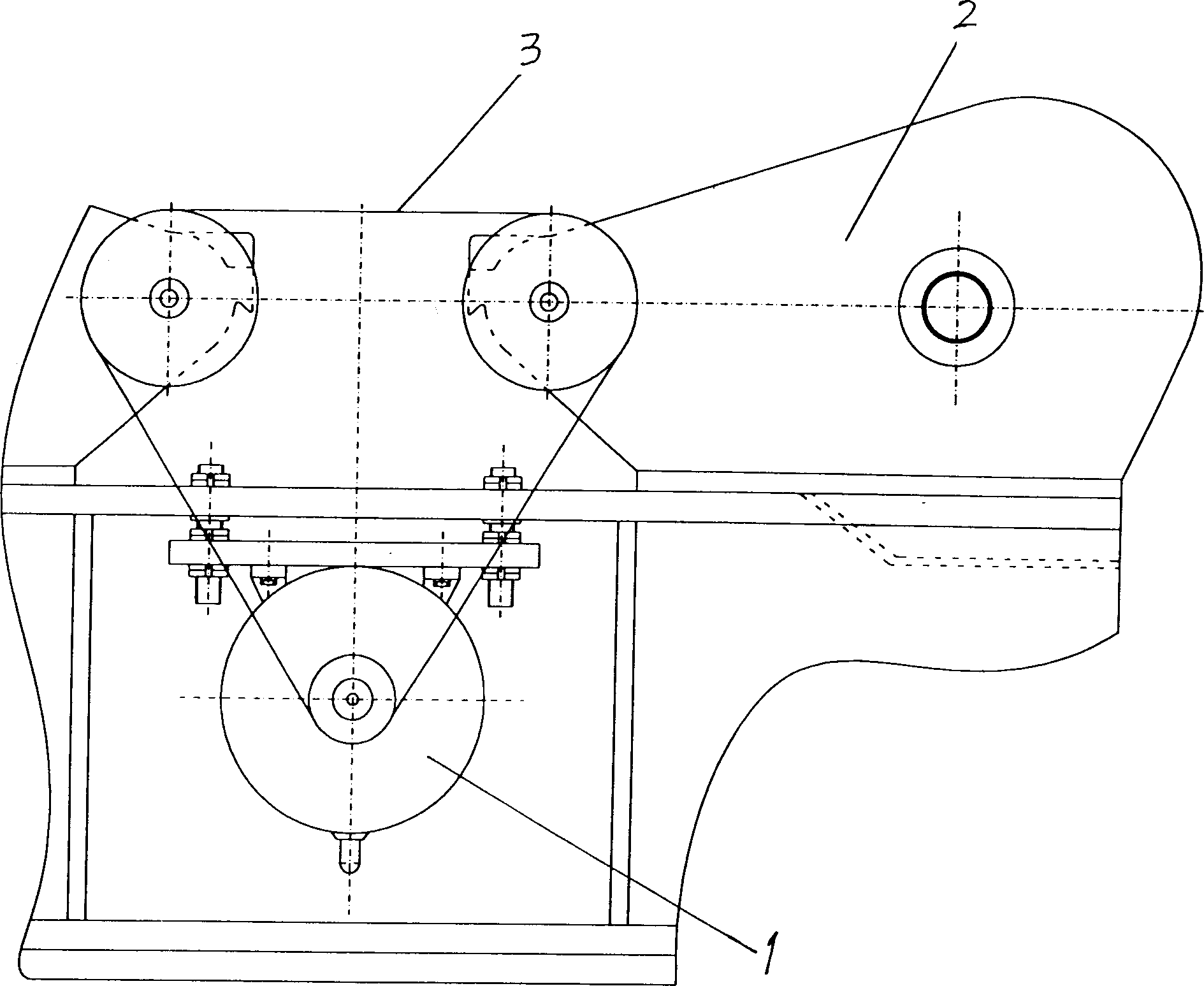

[0020] The pull-out mechanism includes a motor 1, a reducer 2, two lead screws 4, two nuts 5, a horizontal bar 6, a large end cap 7, a roller 10, a roller seat 11, a bottom platform 12, and the like. The pulling-out mechanism of upper roller 9 is positioned at front frame 26 outsides, is used for pulling out, sending upper roller 9. A 37KW motor with a speed of 1480r / min is used. The motor 1 is installed on the bracket 13. The output shaft of the motor 1 is connected to the input shaft of two reducers 2 with the same speed ratio of 48.57 through the synchronous belt 3. The two reducers 2 The output shafts are respectively connected to two T160×24 lead screws 4, and the two ends of each lead screw 4 are supported on bearings, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com