Method and equipment for supplying power in no touch mode through higher harmonics of high-speed magnetic suspension train

A technology for magnetic levitation trains and contactless power supply, which is applied in motor vehicles, railway vehicles, transportation and packaging, etc., can solve the problems of high cost, long time required, and insufficient power supply of on-board batteries, and achieves low cost and convenient implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

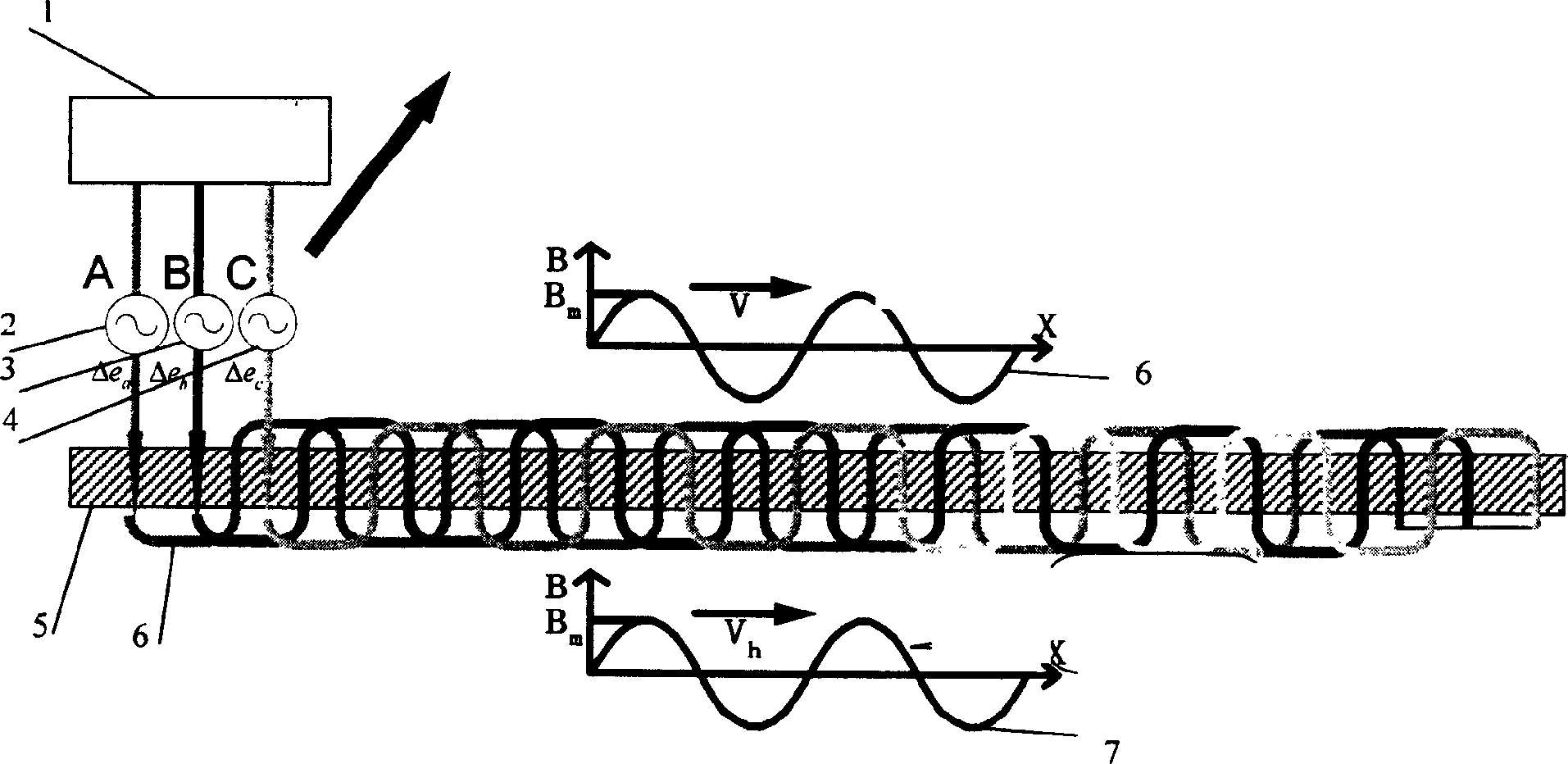

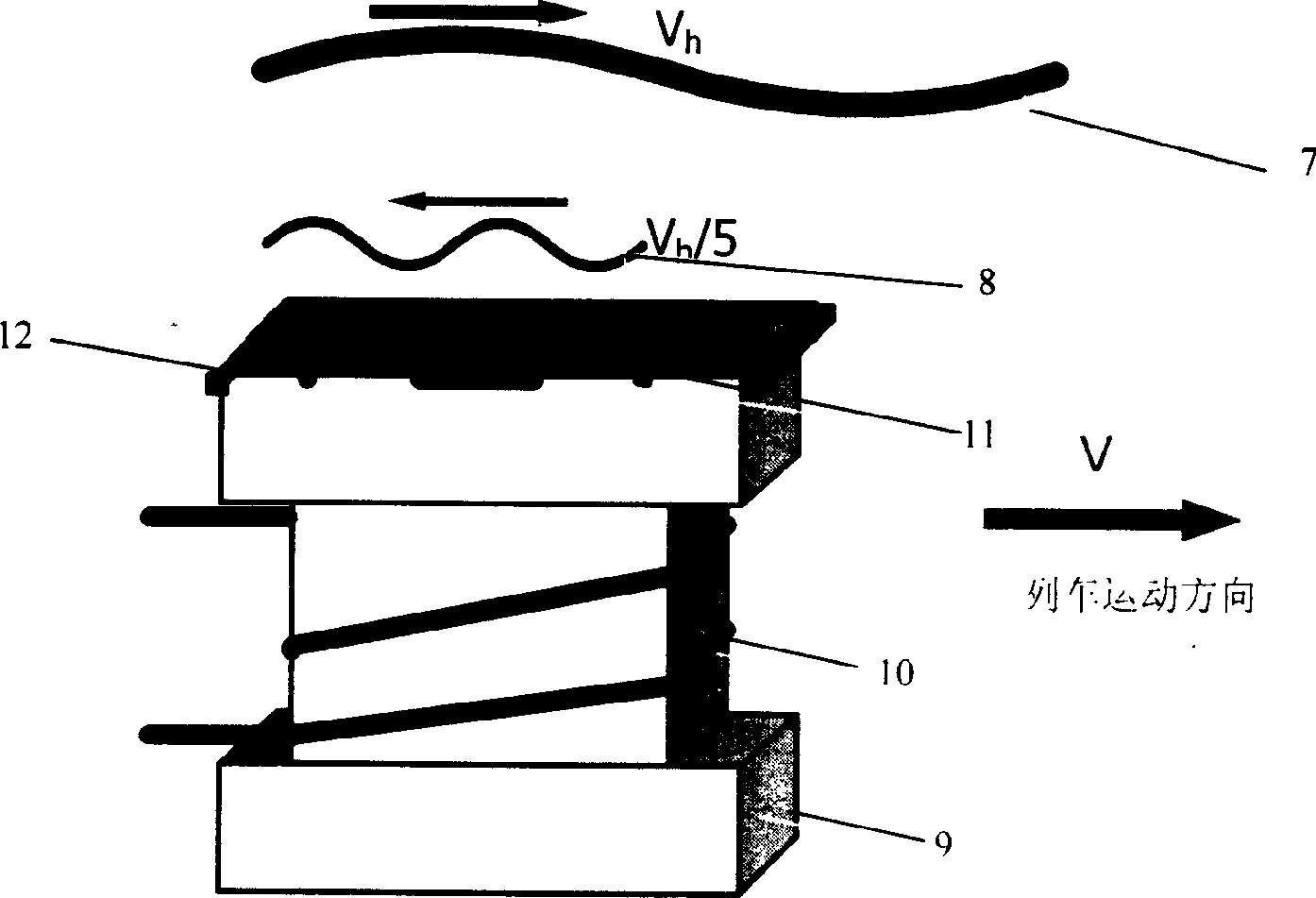

[0022] Now in conjunction with accompanying drawing, the present invention will be further described. Please see first figure 1 with figure 2 , the high-order harmonic non-contact power supply device for maglev trains of the present invention is to set up a high-order harmonic voltage generator near the original ground three-phase frequency converter 1, and the three-phase high-order harmonic voltage output terminal is the same as the original ground three-phase output The terminals are connected in parallel, or a high-order harmonic generated directly by the original ground three-phase inverter 1 is superimposed on the three-phase stator coils 2, 3, and 4 of the original three-phase voltage and output together. A group of linear generator coils 12 is added to the magnetic pole 9 of the train, the original linear synchronous motor coil 11 is embedded on the magnetic pole 9 , and the magnetic pole magnetic field is generated by the exciting coil 10 .

[0023] The three-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com