Method of rolling sheet and rolling machine

A thin plate rolling mill, rolling direction technology, applied in metal rolling stands, metal rolling, metal rolling and other directions, can solve problems such as insufficient mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

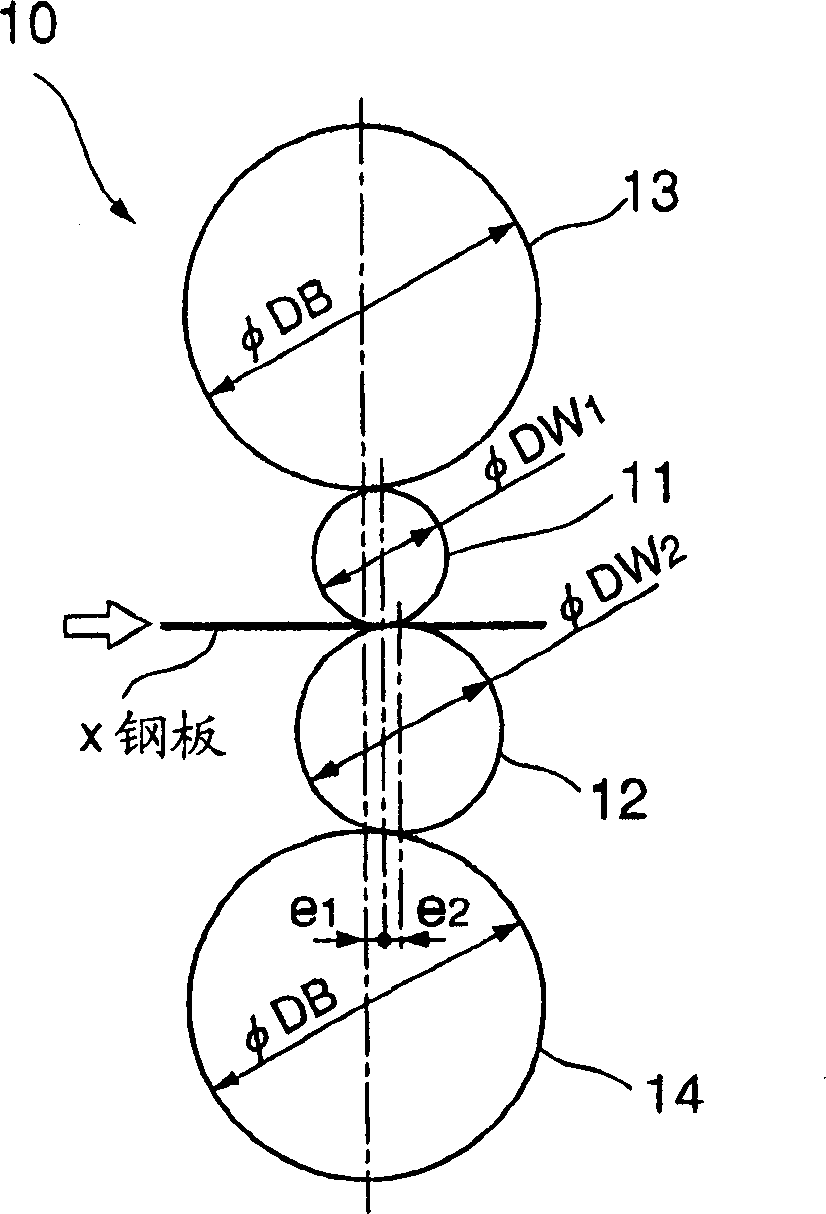

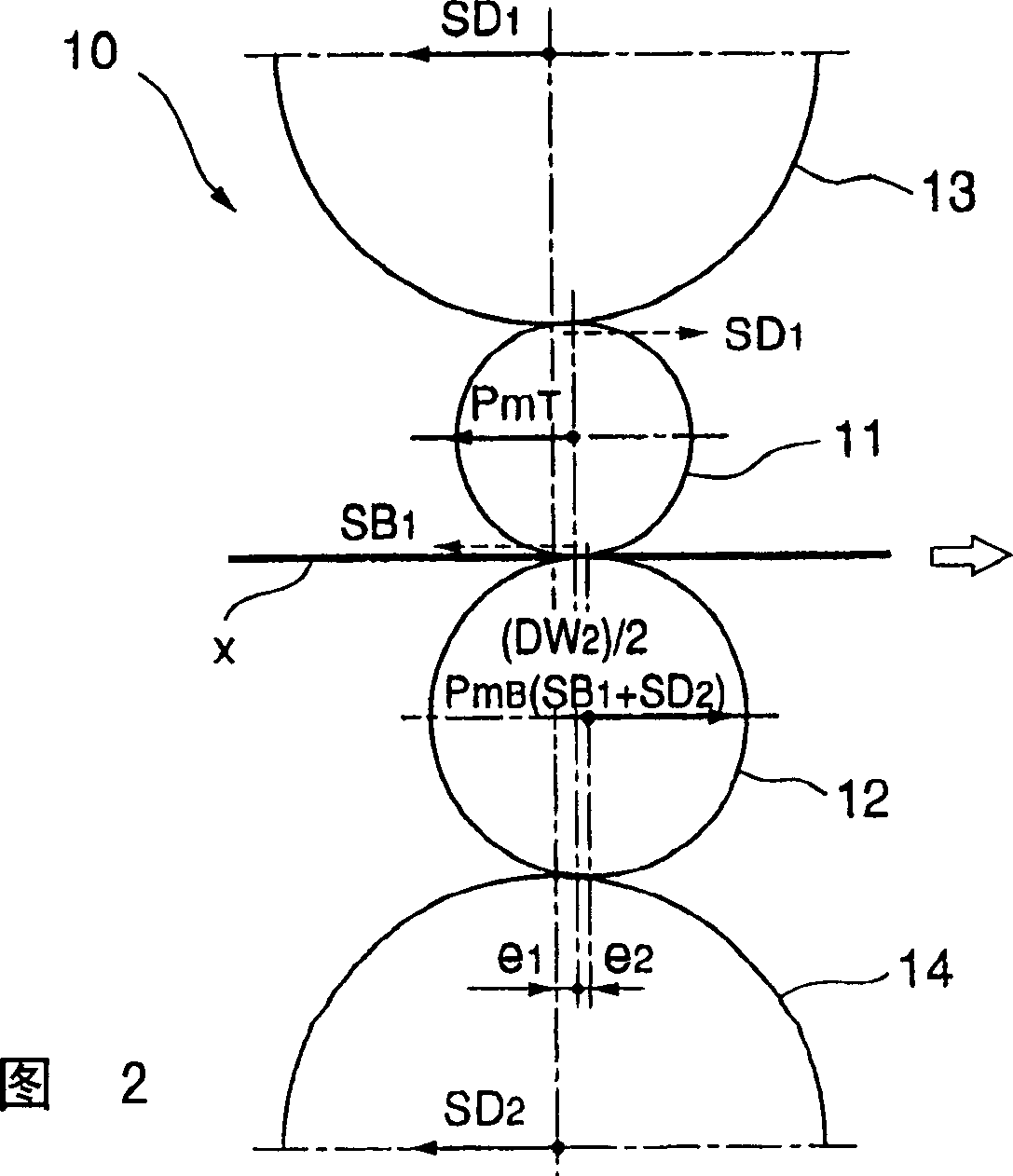

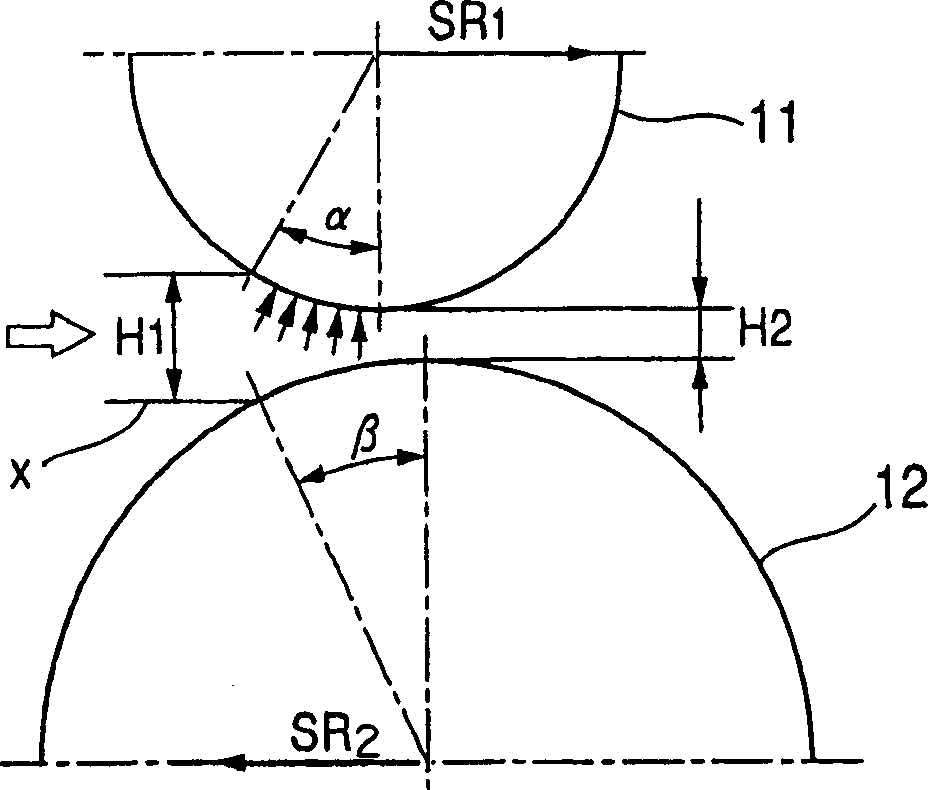

[0043] Figure 1-Figure 7 An embodiment of the invention is shown. figure 1 schematically represented in side view on Figure 7 The basic structure of a rolling mill 10 of one of the rear (downstream side) three-stand rolling mills 1 in the rolling equipment (rolling group) 1 is shown.

[0044] Rolling equipment is equipment for hot rolling thin steel plates such as Figure 7 As shown, it is equipped with a total of six rolling mills 5 and 10 in series. The three-stand rolling mill 5 of the front section (upstream side) is a common four-high rolling mill 5, which consists of a pair of equal-diameter work rolls 6,7 arranged up and down and upper and lower back-up rolls 8,9 supporting the work rolls respectively. The three-stand rolling mill 10 of the rear section is a so-called different diameter rolling mill, and it is provided with a pair of different work rolls 11,12 of diameter between the last back-up roll 13 and the bottom back-up roll 14. Although the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com