Fuel cell power generation system, and fuel cell power generation interrupting method

A fuel cell and power generation system technology, applied in the direction of fuel cells, fuel cell additives, electrochemical generators, etc., can solve the problems of increasing operating costs, increasing the initial cost of machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

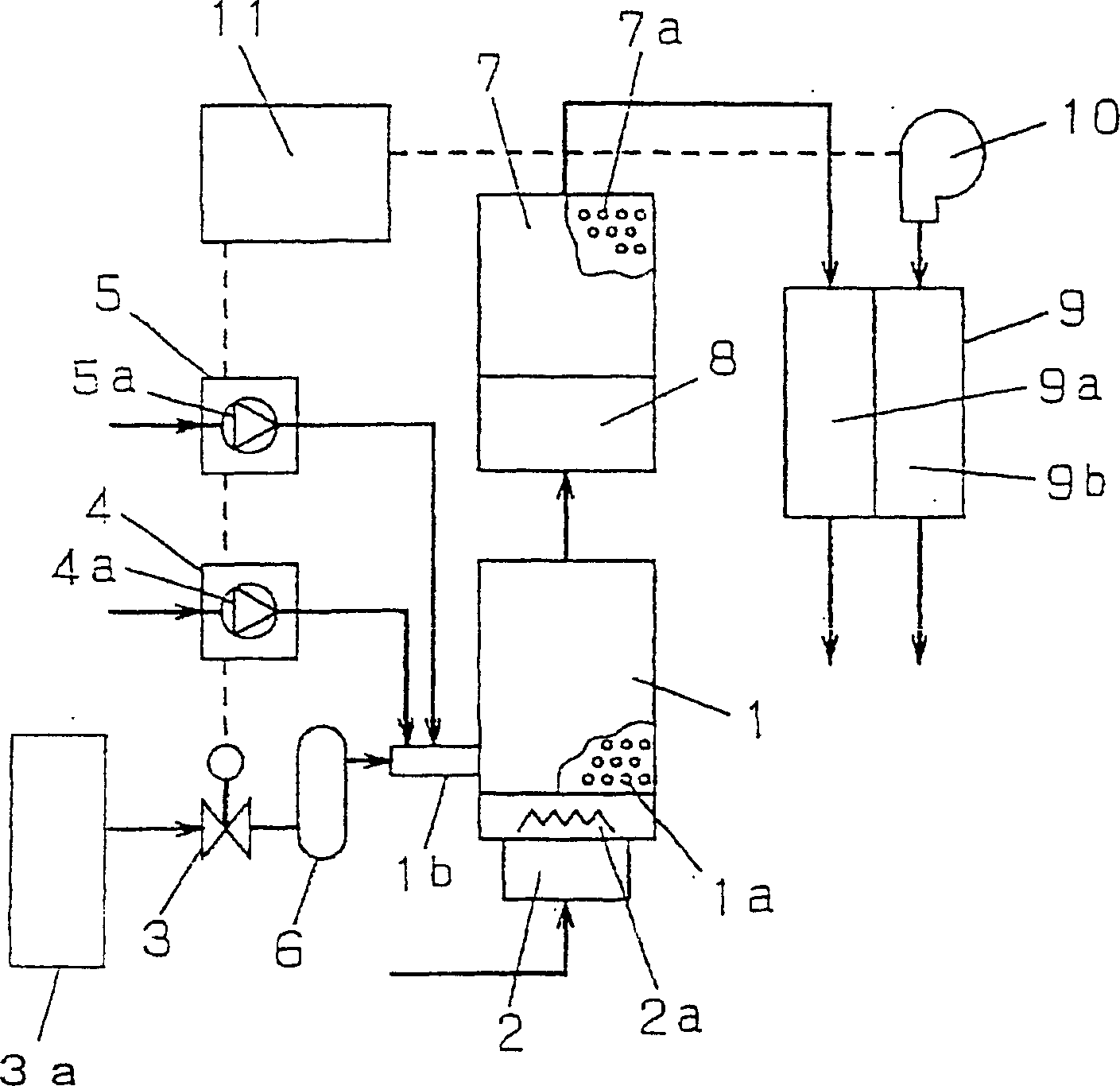

[0047] figure 1 It is a system configuration diagram of the fuel cell power generation system according to Embodiment 1 of the present invention. 1 is a reformer filled with a reforming catalyst 1a for reforming reaction. In the reformer 1, a burner 2a as a heating device 2 is provided, and at the inlet of the upstream 1b of the reformer 1, a raw material gas supply valve 3 is provided, and a water supply device 4 connected to the upstream 1b is provided. Water pump 4a and air pump 5a as air supply device 5 . Furthermore, between the upstream 1b of the reformer 1 and the raw material gas supply valve 3, a desulfurizer 6 for removing sulfur components contained in the raw material gas may be provided. And 3 a is a supply device for supplying raw material gas to the reformer 1 .

[0048] 7 is a carbon monoxide remover connected to the downstream of the reformer 1, and filled with a catalyst 7a for causing a carbon monoxide removal reaction. Between the reformer 1 and the ca...

Embodiment approach 2

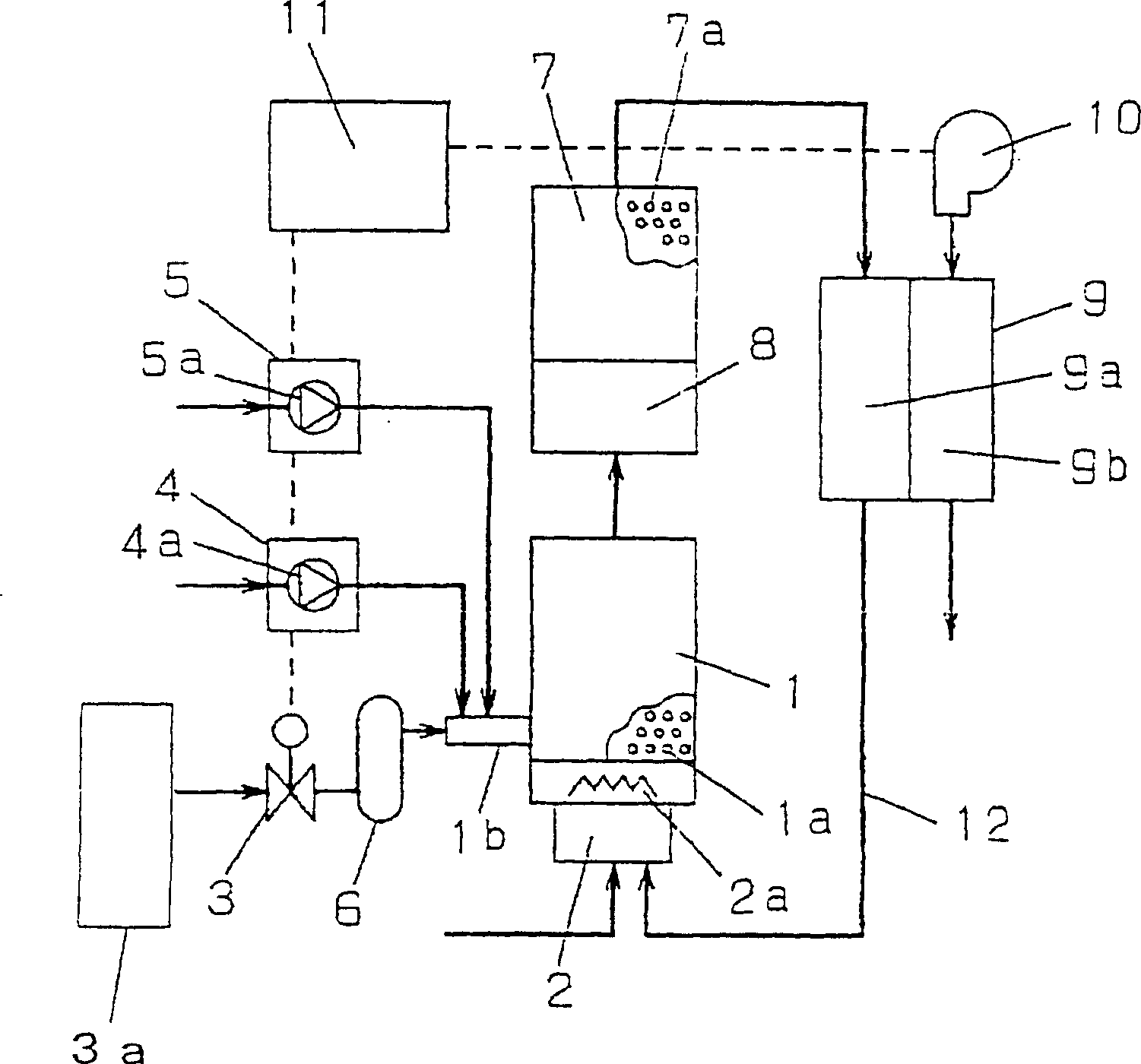

[0060] figure 2 It is a system configuration diagram of the fuel cell power generation system in Embodiment 2 of the present invention. The same symbols are used for the same parts as those in Embodiment 1, and descriptions of these parts are omitted. 12 is a hydrogen discharge connection for supplying waste hydrogen gas discharged from the hydrogen electrode 9a of the fuel cell 9 to the burner 2a.

[0061] Next, the operation of the second embodiment will be described.

[0062] Although most of the hydrogen gas is consumed by the power generation reaction in the hydrogen electrode 9a of the fuel cell 9, a certain amount of hydrogen gas is discharged as waste hydrogen gas. The waste hydrogen is sent into the burner 2a through the hydrogen exhaust connection 12, and is used as fuel to achieve effective utilization, and at the same time, the residual hydrogen is completely burned without being discharged to the outside.

[0063] In the second embodiment, when the power gener...

Embodiment approach 3

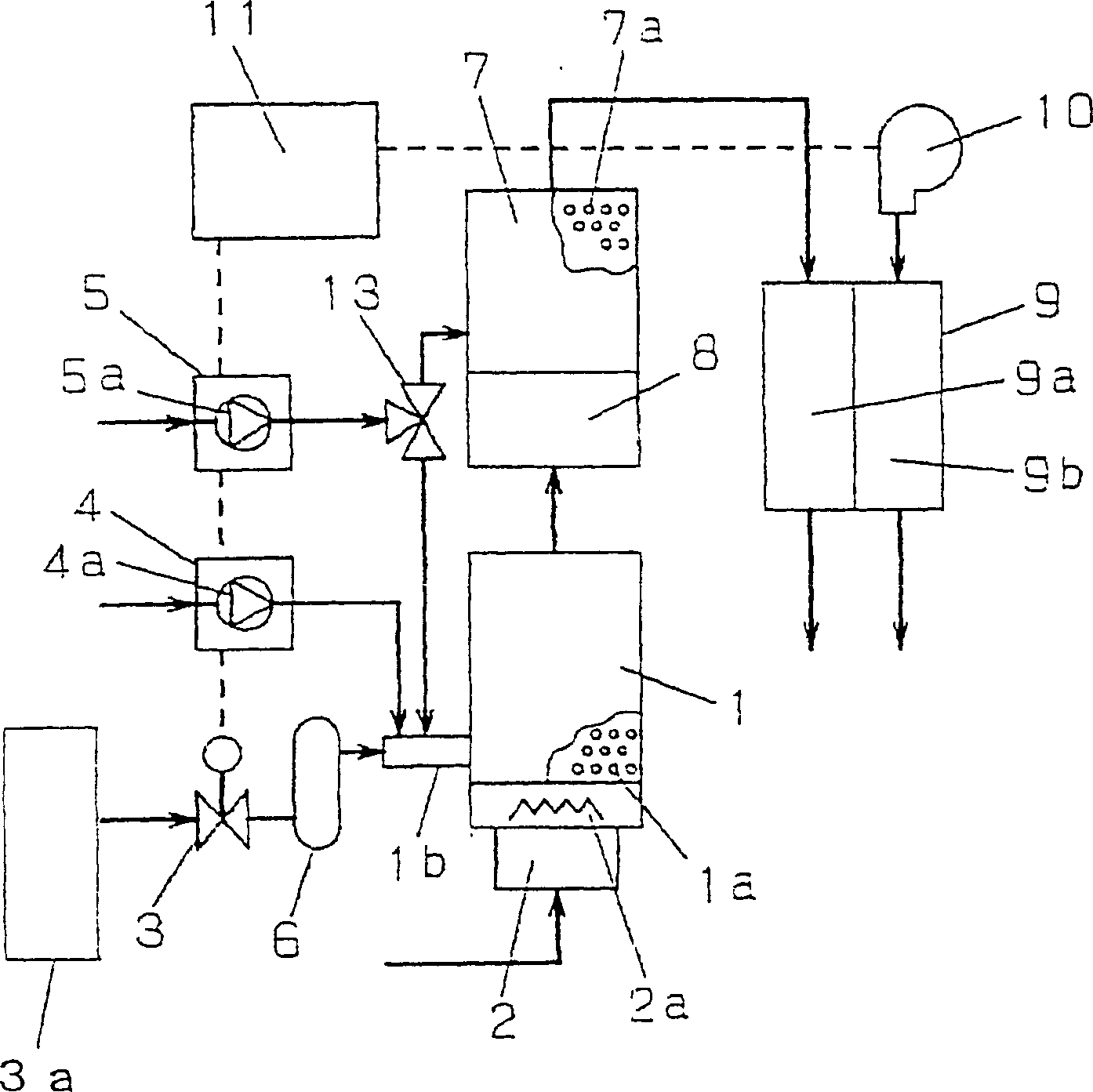

[0067] image 3 is a system configuration diagram of a fuel cell power generation system according to Embodiment 3 of the present invention. The same symbols are used for the same parts as those in Embodiment 1, and descriptions of these parts are omitted. In Embodiment 3, the carbon monoxide remover 7 adopts a selective oxidation trans type that selectively reacts carbon monoxide and air. Although usually in the case of selecting the oxidation method, it is necessary to supply air to carbon monoxide, the air pump 5a as the air supply device 5 also serves as an air supply device, and the switching device 13 switches the air to supply or supply to the carbon monoxide remover 7 as appropriate. It is supplied to the upstream stream 1b of the reformer 1.

[0068] Next, the operation of the third embodiment will be described. In this embodiment, when the power generation operation is stopped, the air pump 5a is used to supply the air for purging water vapor as in the first embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com