Low-temp. two-phase flow gas liquid homogeneous distribution board fin type phase change heat-exchanger

A phase-change heat exchanger and uniform distribution technology, which is applied to heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as uneven distribution of gas-liquid two-phase fluids, and improve the uneven distribution situation , improve heat transfer efficiency, and evenly distribute gas and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

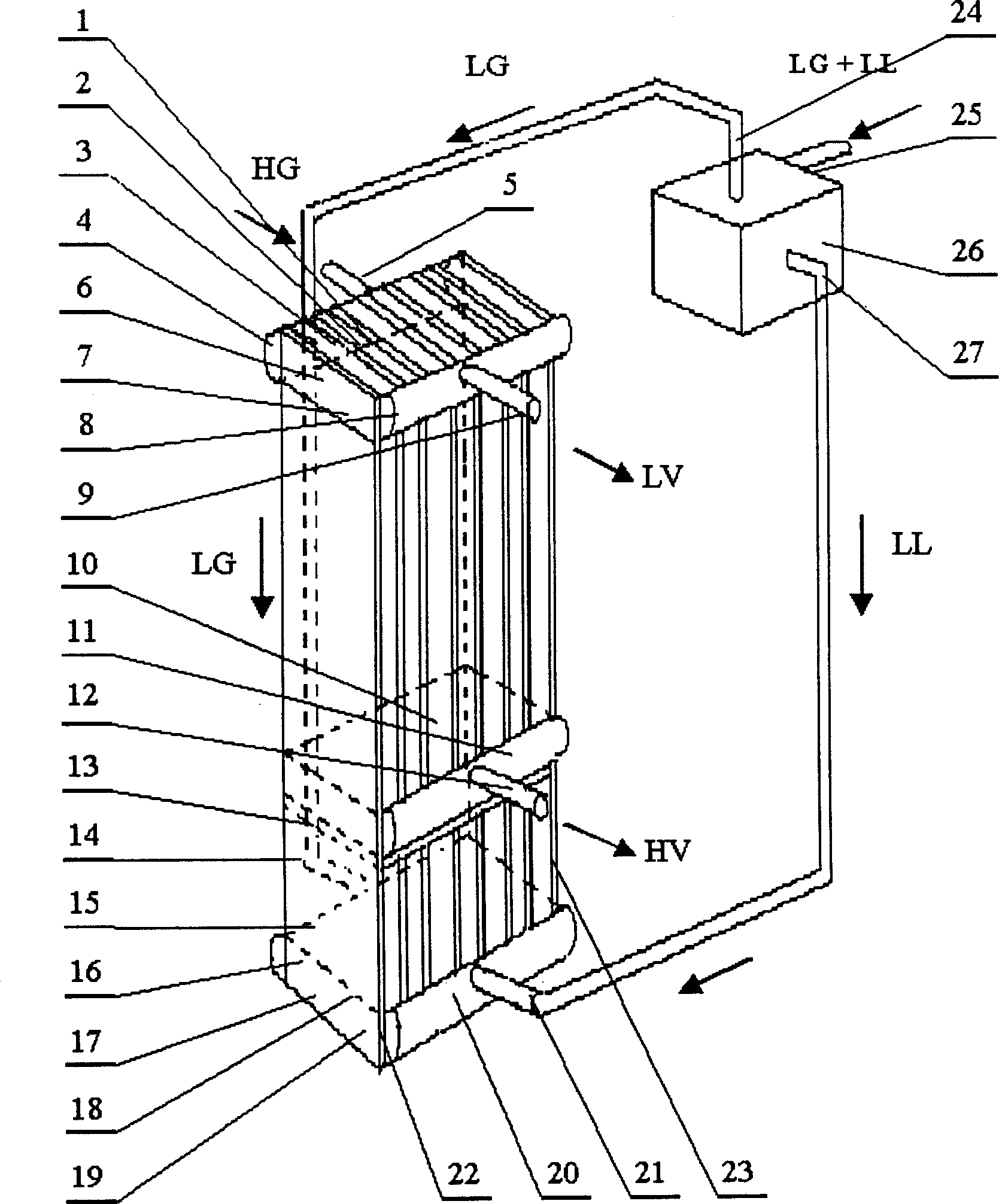

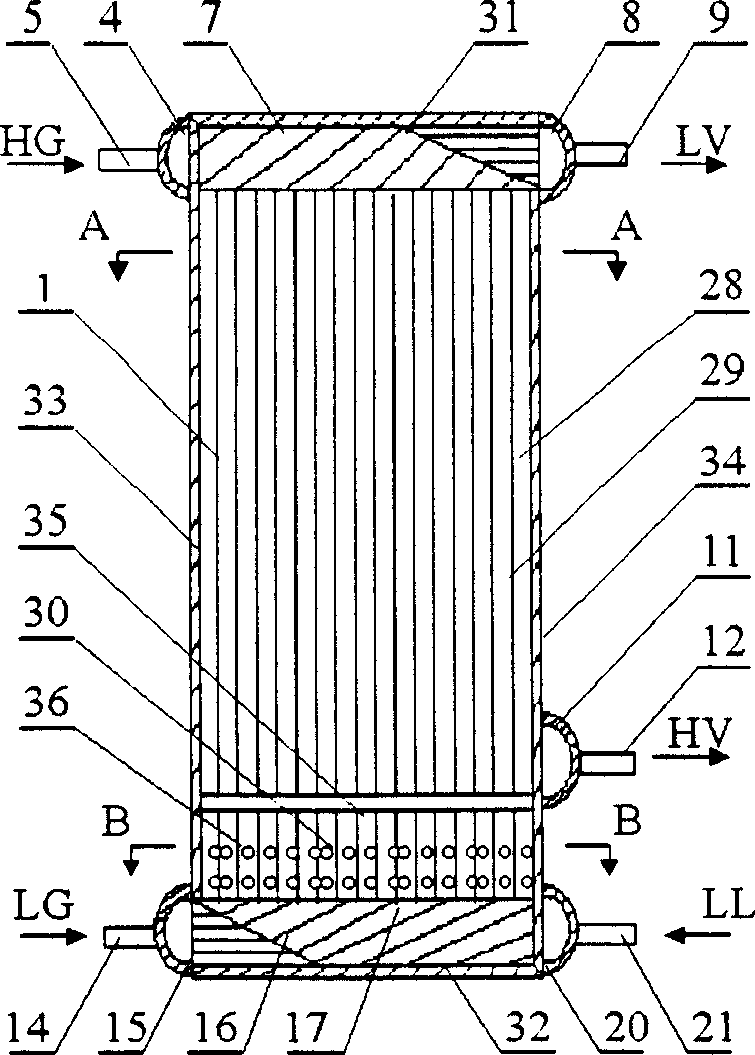

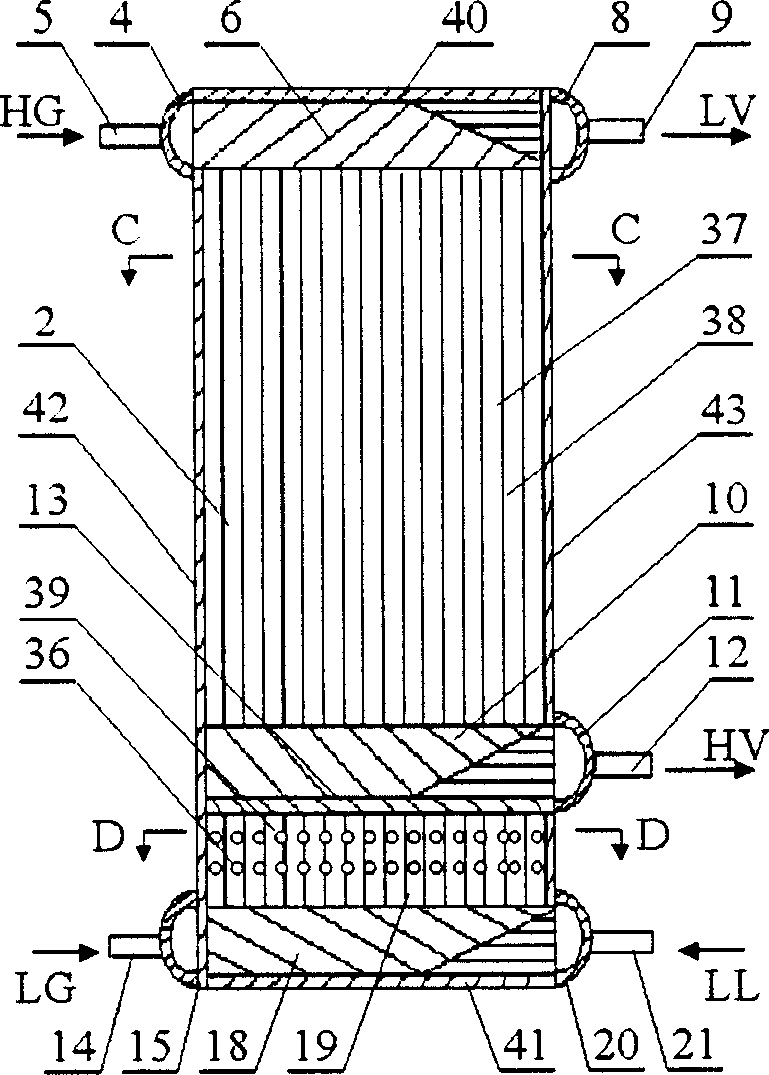

[0019] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , the low-temperature two-phase flow gas-liquid uniform distribution plate-fin phase change heat exchanger of the present invention has a high-temperature gas-phase fluid guide fin 6 on its upper part, and it is connected with the high-temperature gas-phase fluid inlet head 4 and the inlet pipe 5 on the left side. The upper part is also provided with a low-temperature wet steam guide fin 7, which communicates with the low-temperature wet steam outlet head 8 and the outlet pipe 9 on the right side; the middle part is provided with a high-temperature wet steam collection guide fin 10 , it communicates with the high-temperature wet steam collecting head 11 on the right side and the collecting outlet pipe 12, and a middle spacer 13 is arranged below it.

[0021] exist figure 1 Among them, the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com