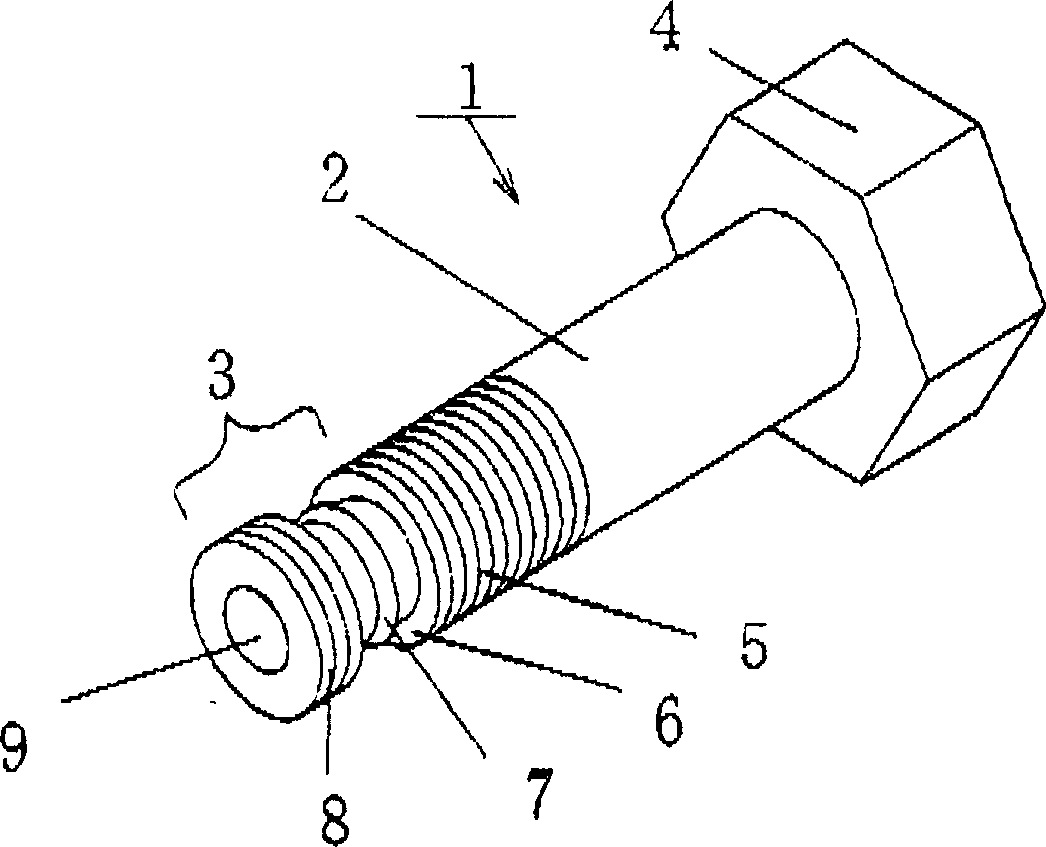

Fastener structure, bolt and nut with said structure and making method thereof

A technology for fastening parts and locking nuts, applied in the direction of threaded fasteners, locking fasteners, nuts, etc., can solve the problems of increased friction type, difficult to remove, lack of repeated use, etc., to prevent threads Relaxed, high-tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0390] The present invention will be described more specifically by way of examples below. In addition, the present invention is not limited to these Examples.

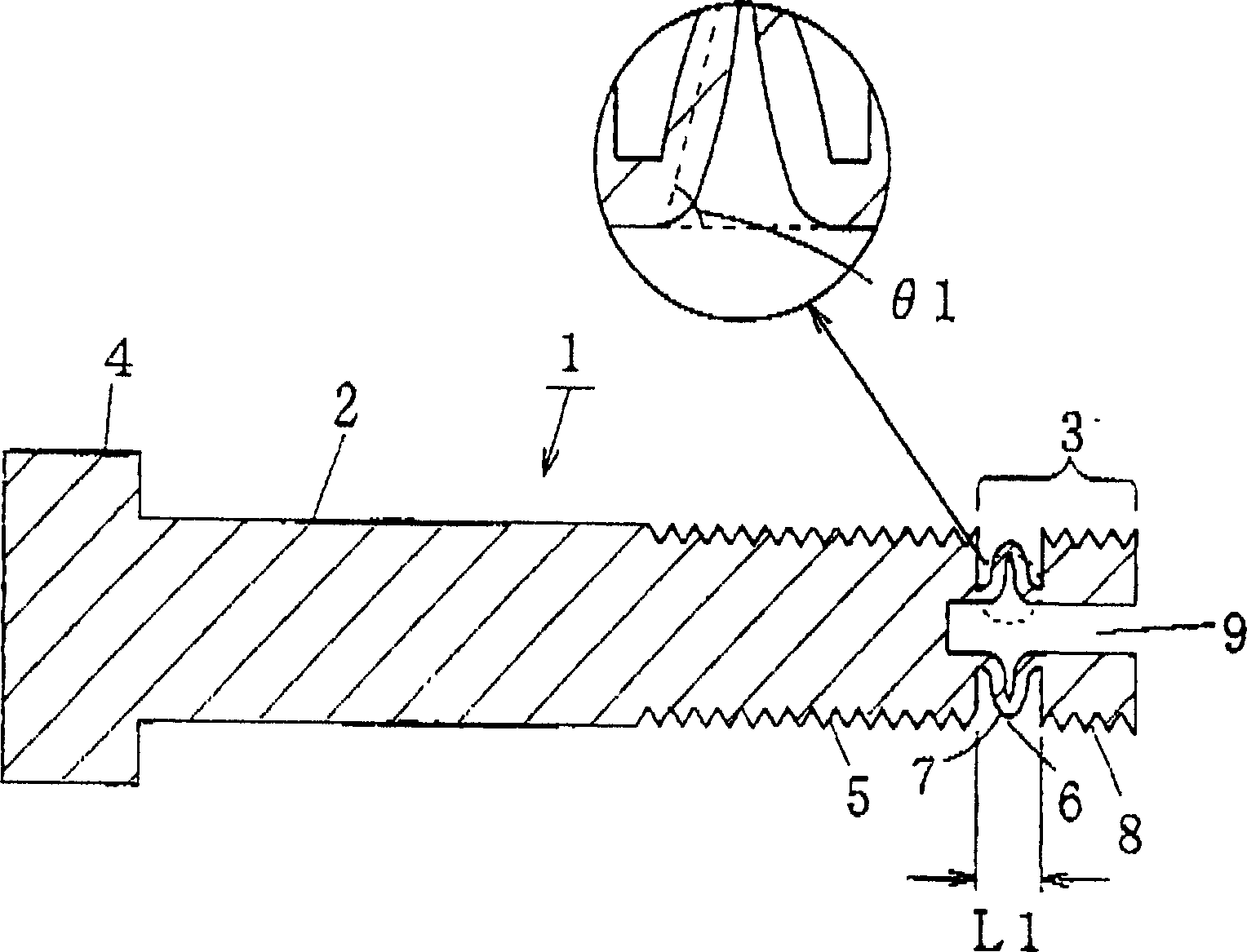

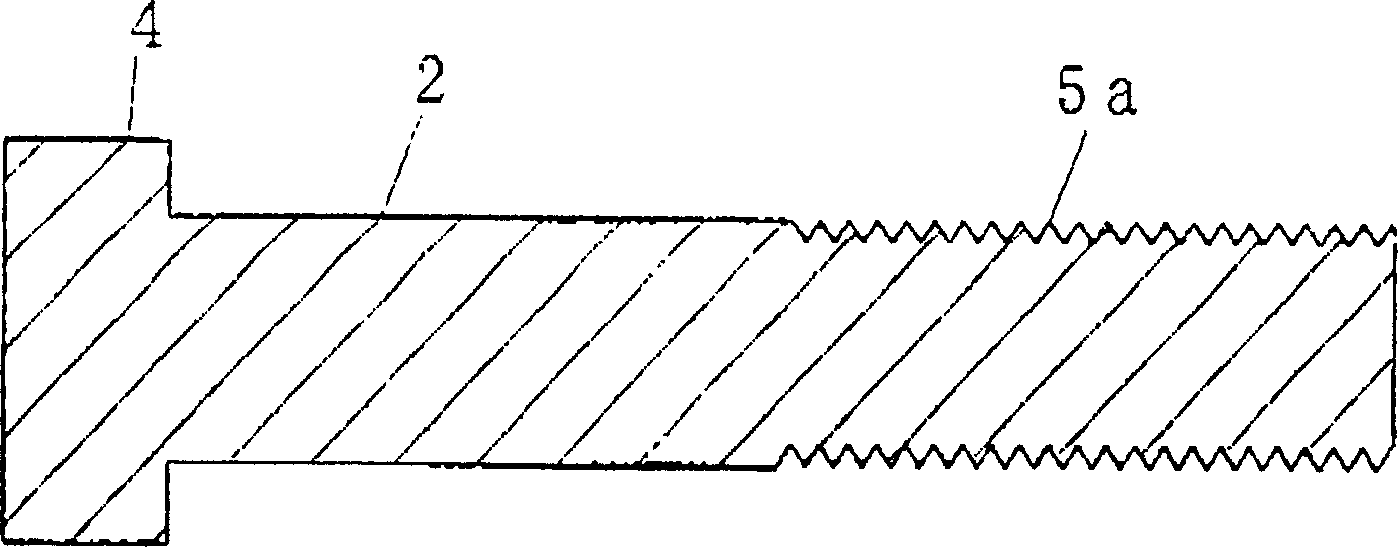

no. 1 Embodiment

[0392] Manufacture the lock nut of the first embodiment, which relates to the lock nut described by the third embodiment, wherein the pitch (P') of the main internal thread part and the secondary internal thread part is 2mm, and the main internal thread part and the secondary internal thread part The diameter (root diameter) of the thread root of the internal thread portion was 16 mm, and the axial deformation amount (deformation amount γ) of the nut elastic portion was 1.47 mm.

no. 2 Embodiment

[0394] Except that the amount of deformation γ is 1.57 mm, the same as the first embodiment, the production of the second

[0395] Example lock nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com