Checking marker and electronic machine

A marking and electrical conduction technology, which is applied in the direction of assembling printed circuits, instruments, circuits, etc. with electrical components, can solve the problems of difficult to grasp the contact area between leads, unable to reduce the load of microscope inspection process, and unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

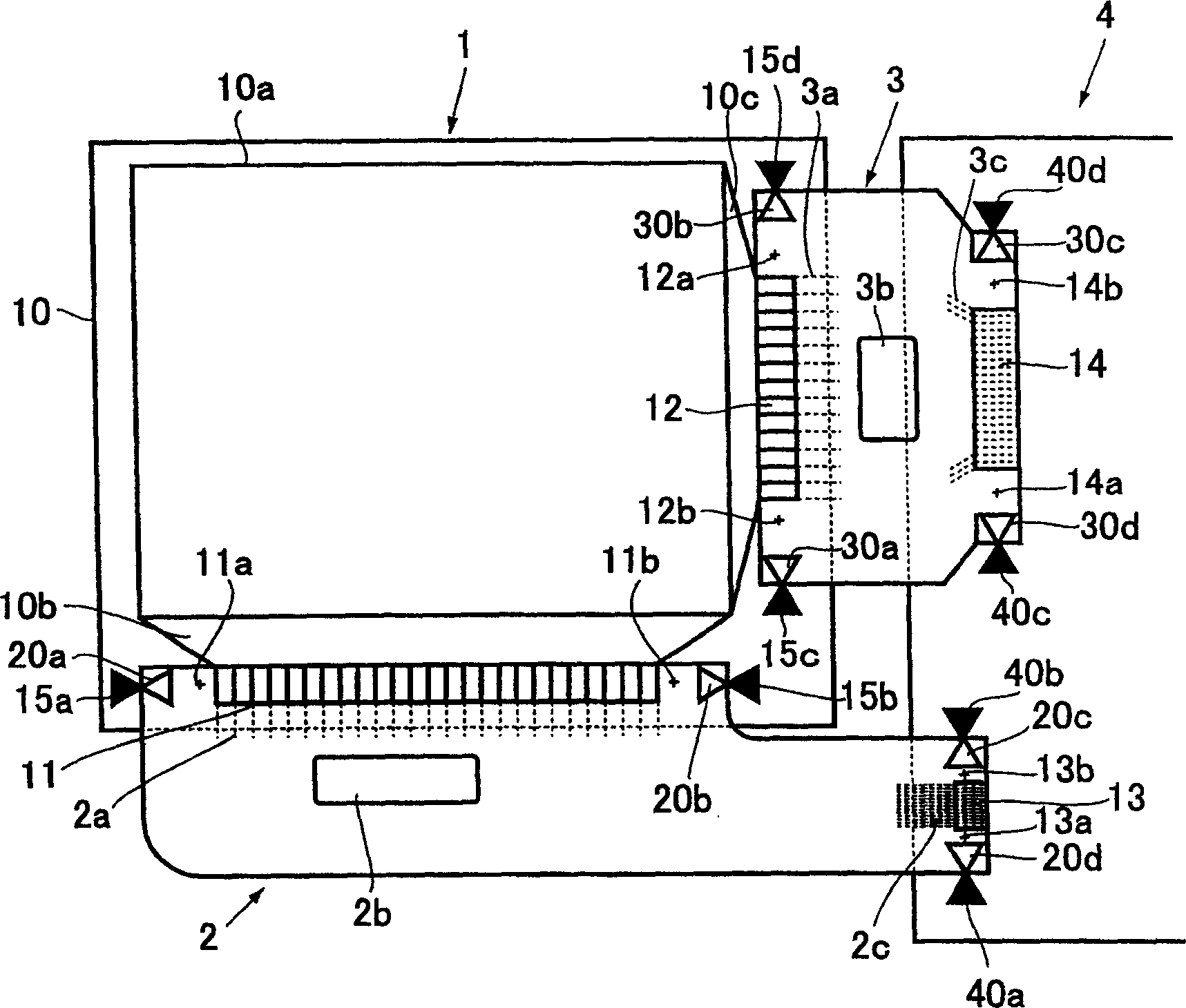

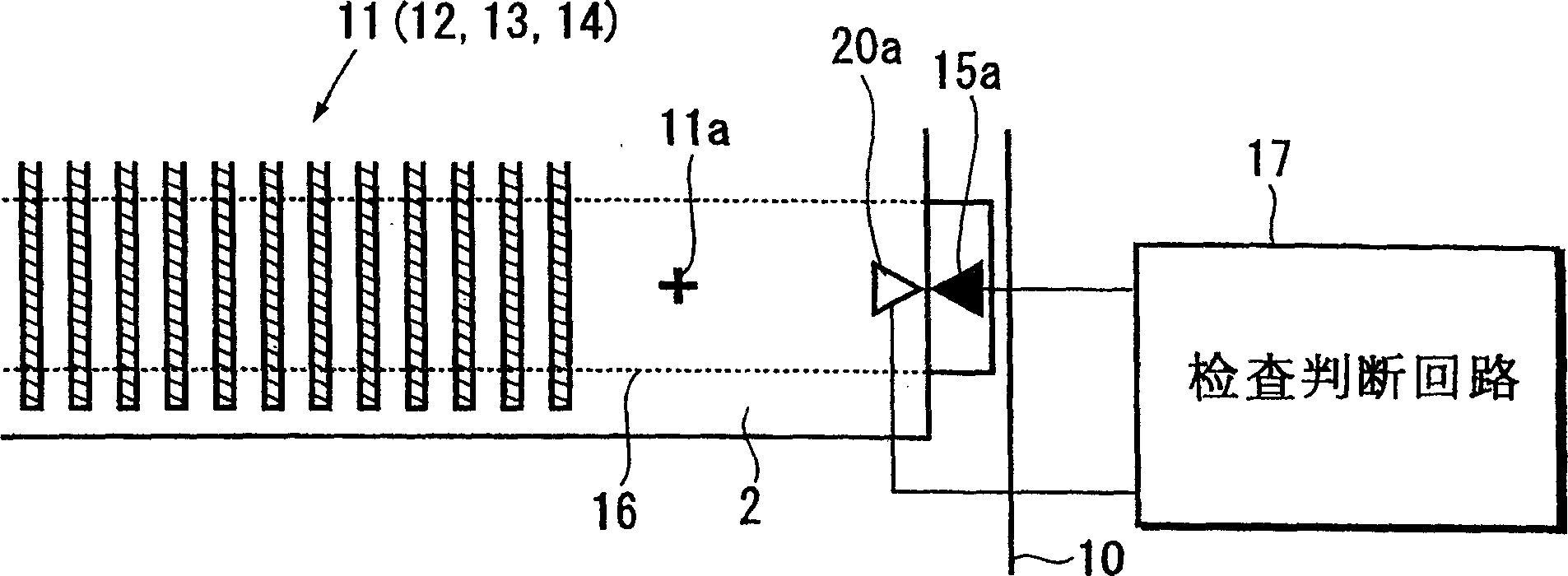

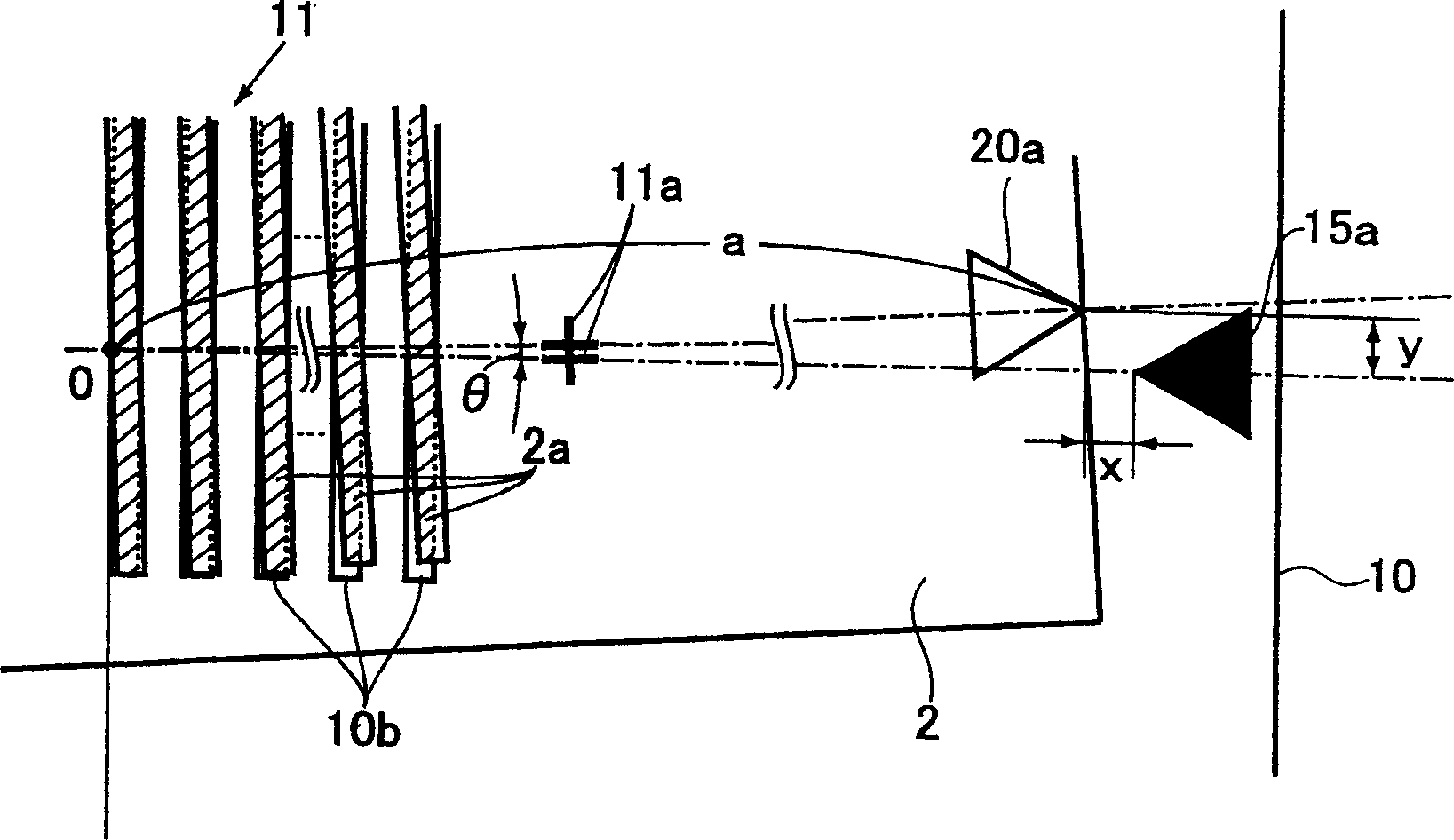

[0037] Embodiments of the present invention are described below in conjunction with figures. figure 1 A schematic diagram for revealing an embodiment of the present invention, revealing the assembly status of the electronic components of the display panel and the condition of markings for disposition inspection. In the figure, 1 is an organic EL display panel, 2 and 3 are TAB substrates, and 4 is a flexible substrate.

[0038] On the panel substrate 10 of the organic EL display panel 1, lead wires 10b, 10c used as signal lines are drawn out from the screen area 10a. , 3a are connected. The lead wires 2 b and 3 b are bonded to the driver ICs of the TAB substrates 2 and 3 .

[0039] The lead wires 2 c and 3 c of the TAB substrates 2 and 3 facing the flexible substrate 4 are connected to the connection areas 13 and 14 on the flexible substrate 4 by the connection wires on the flexible substrate 4 . Moreover, in the vicinity of the aforementioned connecting regions 11, 12, 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com