Pot type vacuum cleaner

A vacuum cleaner and canister technology, applied in the direction of vacuum cleaners, suction nozzles, suction hoses, etc., can solve the problems of inconvenience for users, re-contamination of cleaning fluid in cleaning areas, and increased costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

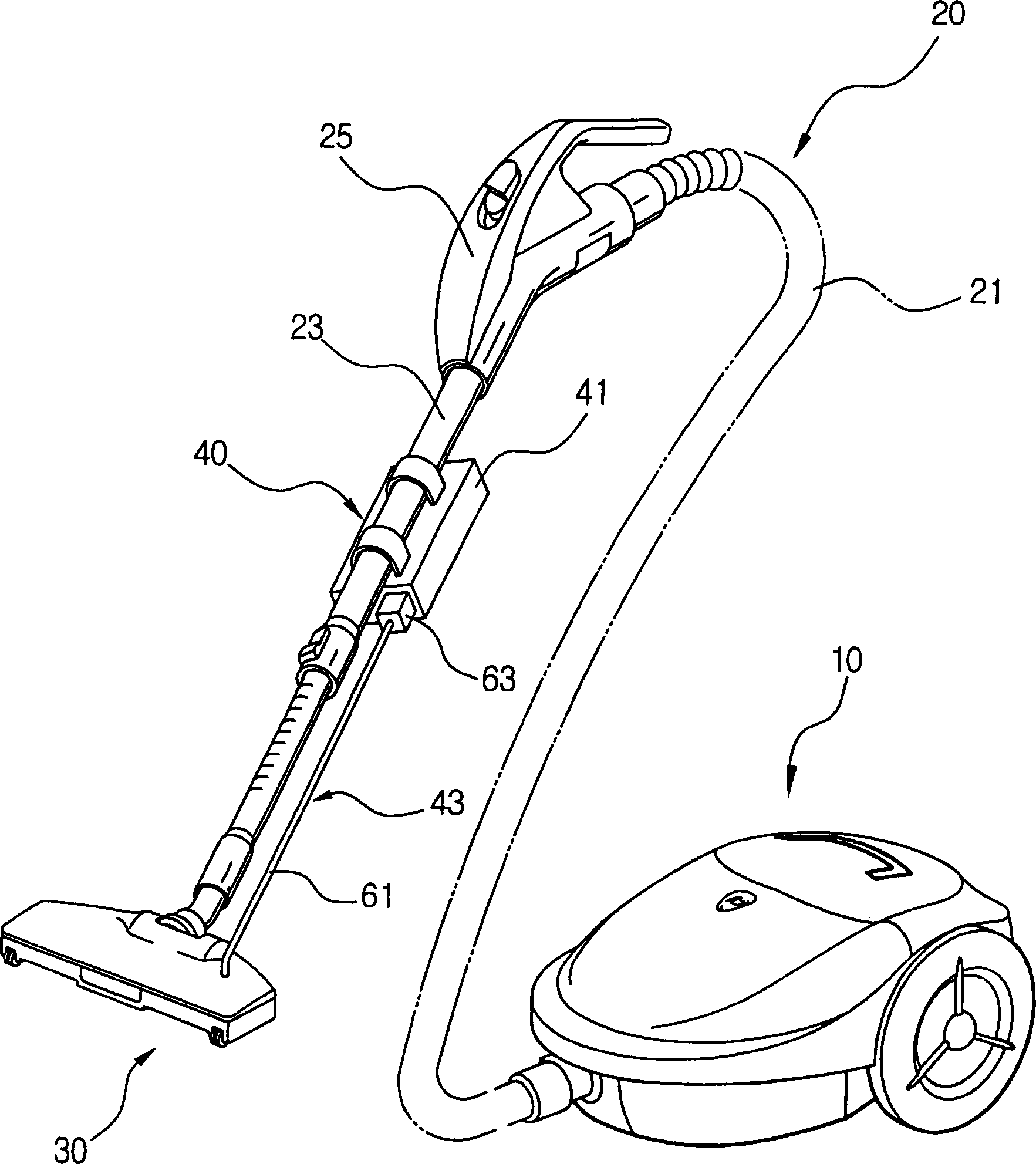

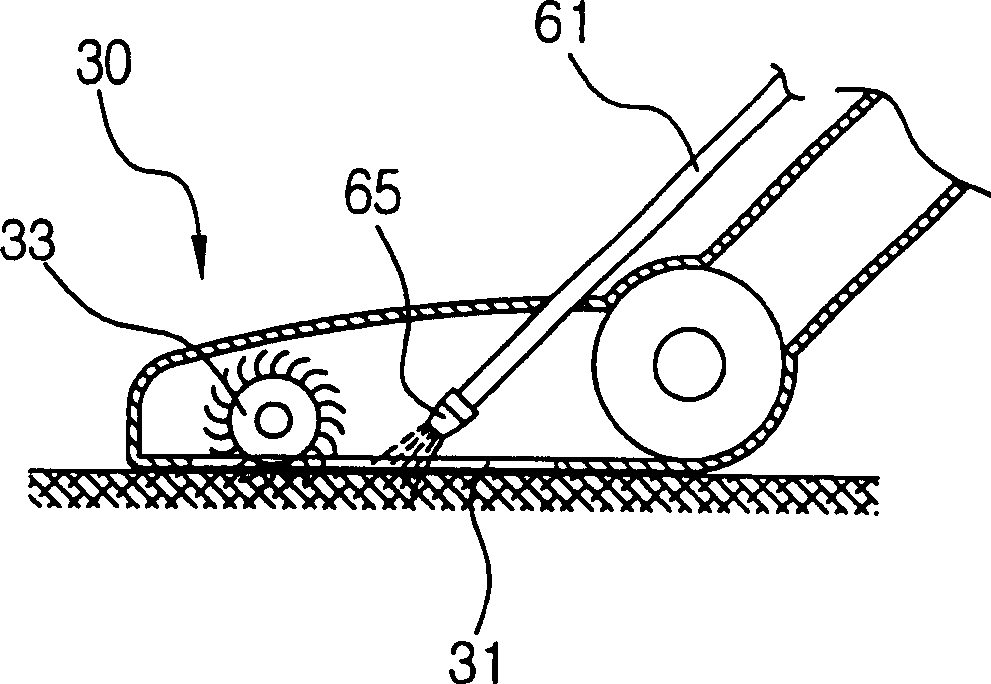

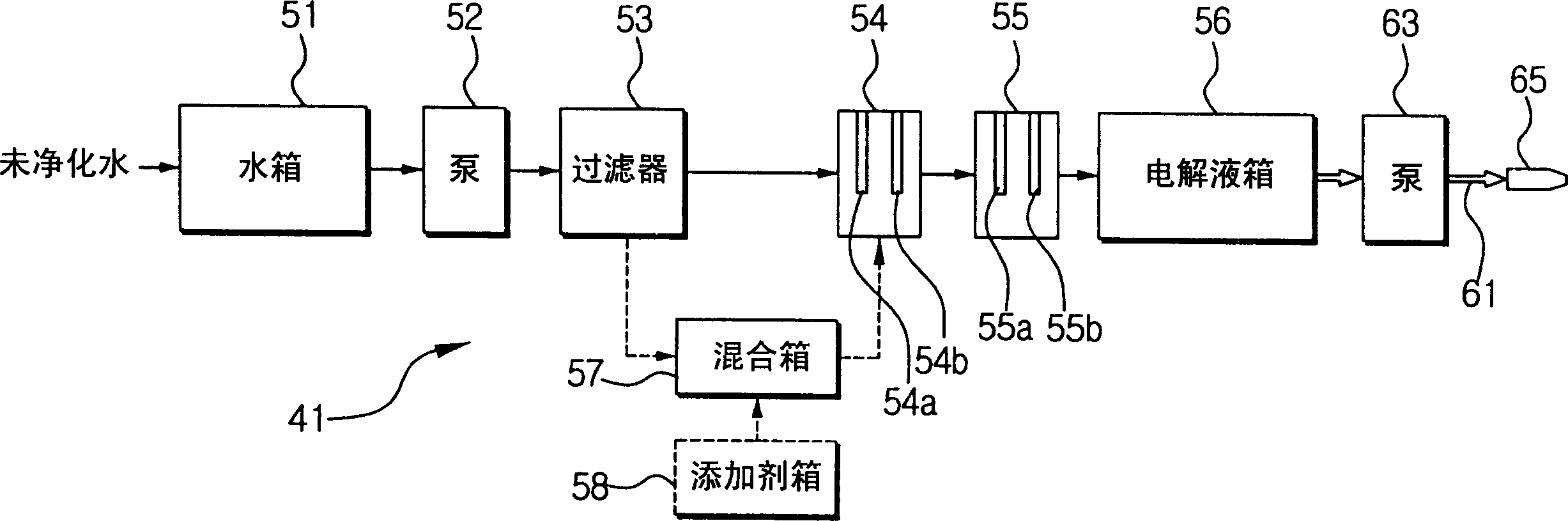

[0019] Such as figure 1 As shown, the canister vacuum cleaner according to the preferred embodiment of the present invention includes a vacuum cleaner main body 10, an extended suction pipe 20 connected to the vacuum cleaner main body 10, a suction brush 30 arranged on one end of the extended suction pipe 20, and a suction brush 30 arranged on the extended suction pipe. Electrolyte supply device 40 on 20.

[0020] Like a general vacuum cleaner, the vacuum cleaner main body 10 has a driving unit and a dust storage chamber respectively formed therein. The drive unit has a drive motor that generates suction. A dust collection filter or cyclone dust collection device is provided in the ash chamber to filter pollutants from the inhaled air.

[0021] If the suction brush 30 has a function of sucking liquid in addition to sucking the pollutants, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com