Method for integrated covering single-pitch roof by using photocell board and large tile forming covering material

A photovoltaic panel and single-slope roof technology, which is applied in photovoltaic power generation, photovoltaic module support structure, roofing using tile/slate tile, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

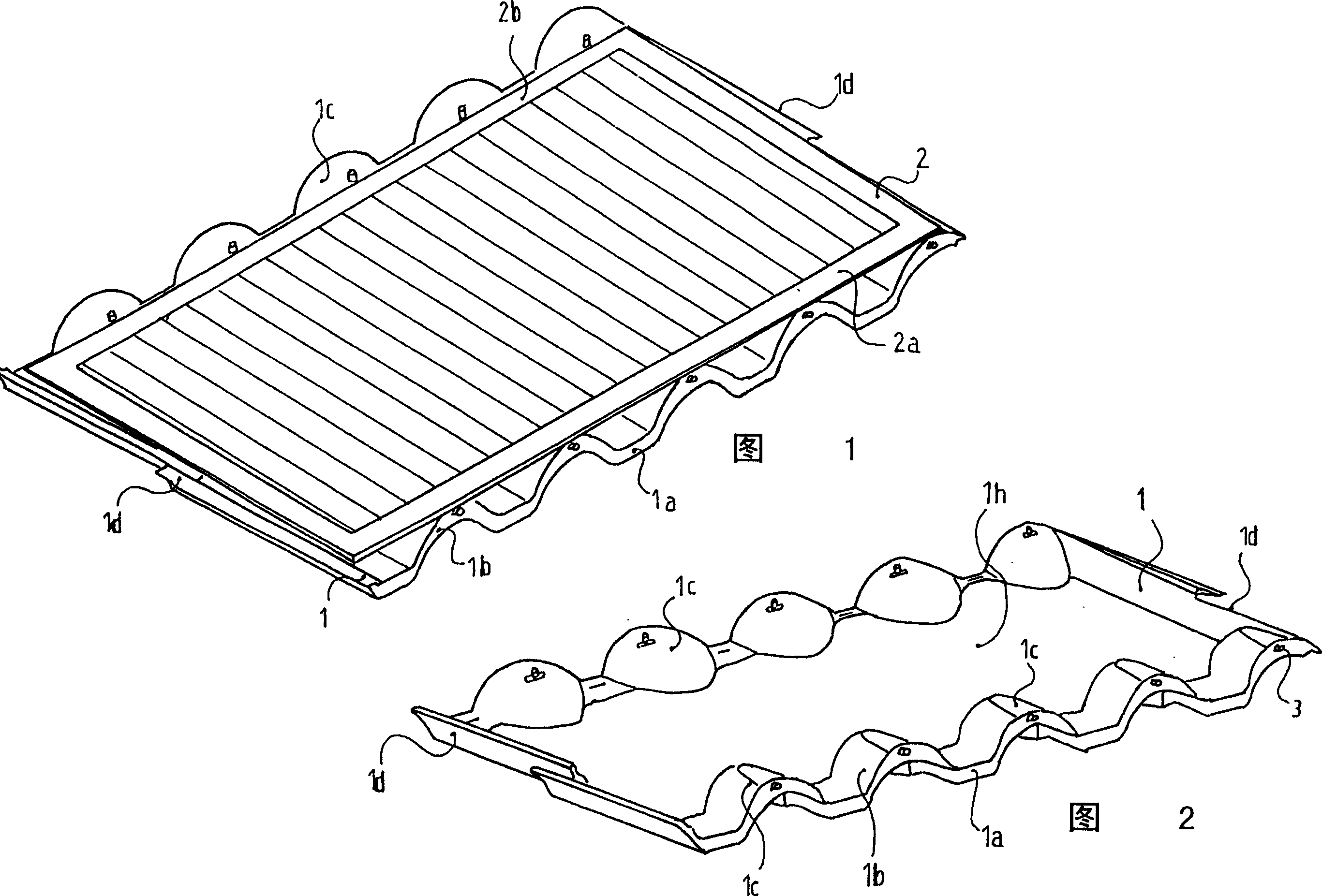

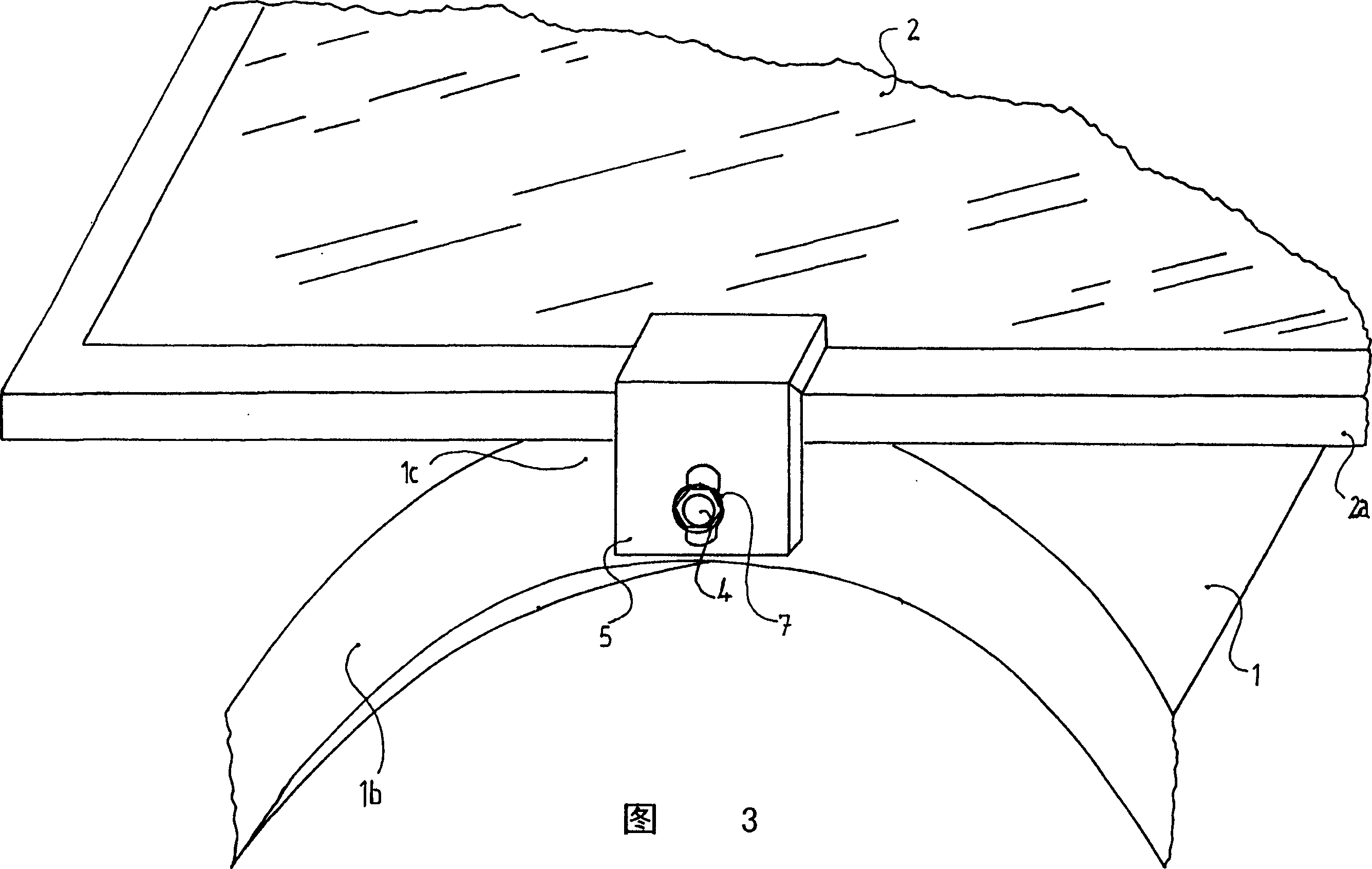

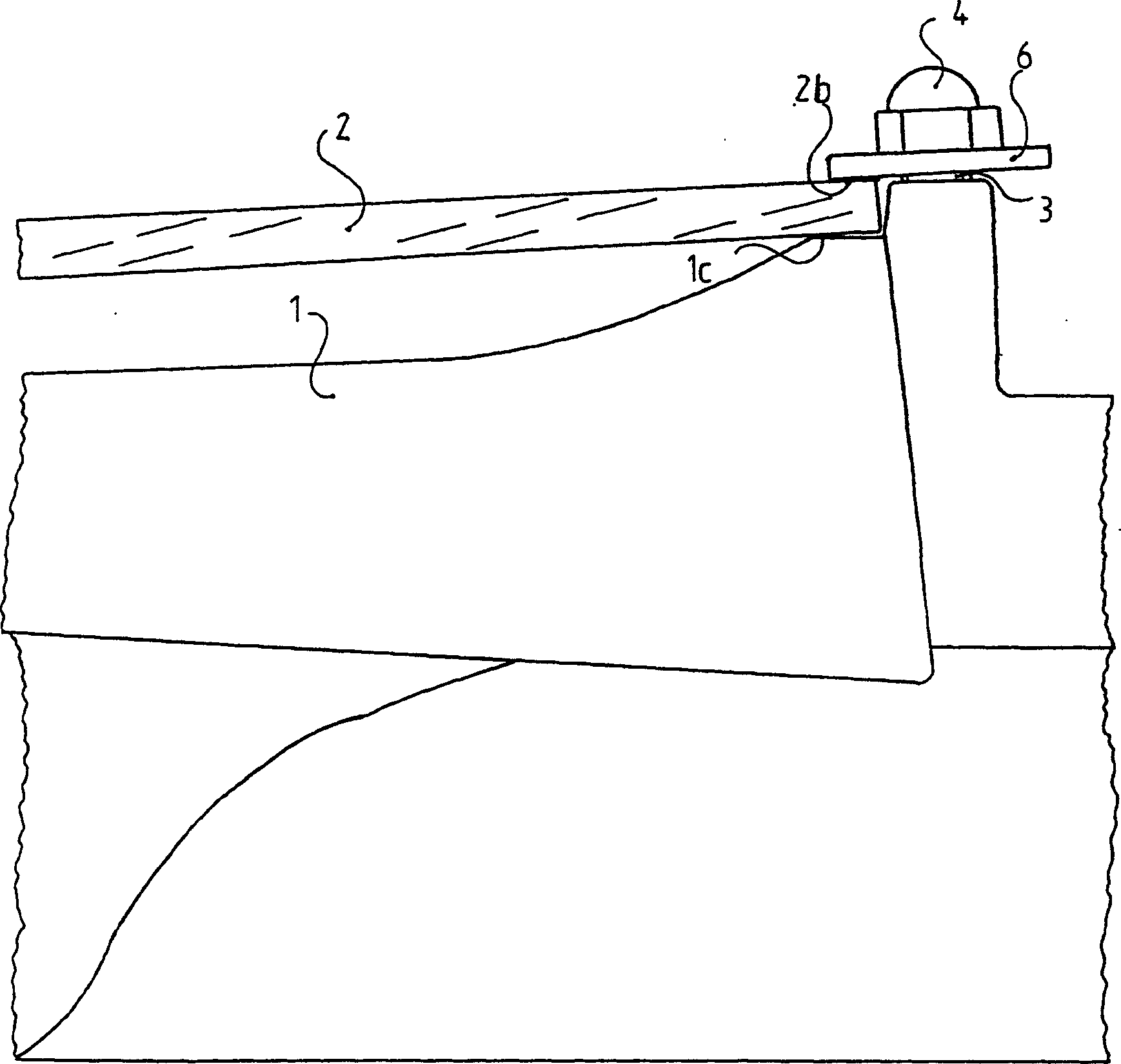

[0028]Please refer to shown in Fig. 1~4, the method of the present invention provides a kind of big big tile 1, and it is to make with the mould after the glass fiber reinforced concrete mixture is melted, then by the outer profile of big tile 1 in A photovoltaic panel 2 is defined thereon. The large tile 1 has an outer contour 1a, and the outer contour 1a is the same as the contour shape of a traditional tile, and its central part bends to a curved part 1b, and the curved part 1b goes up to a flat part 1c, on which the photovoltaic panel 2 rests . The side walls 1d of the large tiles can be combined (matched) with the conventional tiles that the large tiles 1 use for the rest of the roof if the contours of their connecting parts are continuous and complementary to each other. In addition, there is a fixing portion 1g on the underside of the outer side of the curved portion 1b for permanently fixing the photovoltaic cell-large tile to the supporting structure of the tile. Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com