Electric vehicle, liquid delivery device adaptive to electric vehicle, and heat dissipation method

A technology of electric vehicles and infusion devices, which is applied in the direction of electric vehicle charging technology, electric vehicles, battery/fuel cell control devices, etc., can solve the problems of increasing energy consumption, achieve the effect of reducing load weight, increasing cruising range, and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

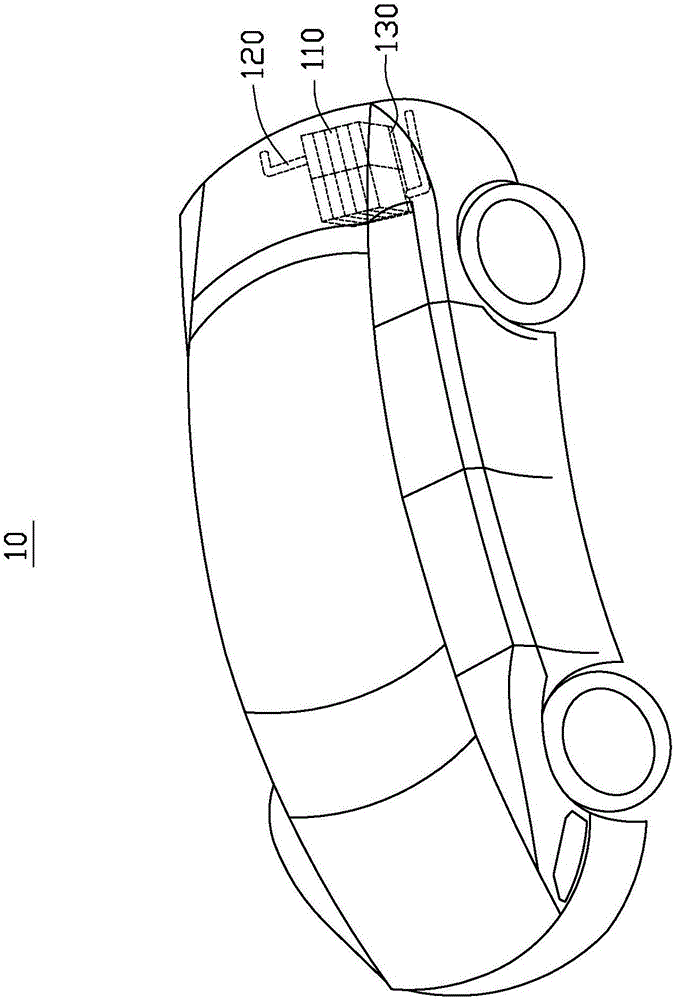

[0058] see figure 1 , an electric vehicle 10, comprising an electric vehicle battery pack 110 arranged at the rear of the electric vehicle, and a cooling device for dissipating heat from the electric vehicle battery pack 110.

[0059] The heat dissipation device includes a heat dissipation pipe 120 and a phase change material heat sink 130 , the phase change material heat sink 130 is adhered to the bottom of the battery pack 110 , and contacts with the battery pack 110 to form heat conduction. The size of the phase change material heat sink 130 matches the bottom of the battery pack 110 . Preferably, the phase change material radiator 130 is expanded graphite with a size of 283×274×10mm.

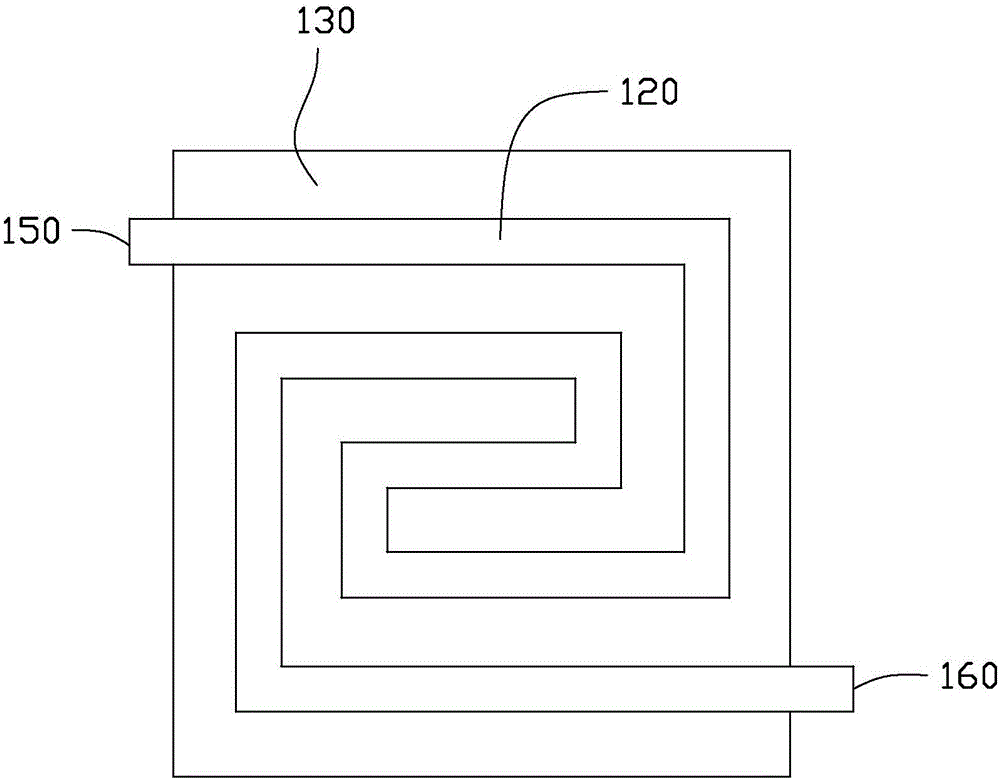

[0060] see figure 2 , the heat dissipation pipes 120 are embedded in the phase change material heat dissipation body 130 and are distributed in a "back" shape. The phase change material radiator 130 conducts the heat of the battery pack 110 to the heat pipe 120 . The heat pipe 120 has a...

Embodiment 2

[0073] see Figure 9 , the present invention provides an electric vehicle 20 in yet another embodiment, the structure of the electric vehicle 20 is basically the same as that in the first embodiment. The difference is that the battery pack 110 is arranged on the front of the electric vehicle, and the phase change material radiators 130a and 130b are adhered to the top and bottom of the battery pack 110 at the same time. The heat dissipation pipes 120 are respectively embedded in the phase change material radiators 130a and 130b, the heat dissipation pipes 120 enter from the phase change material radiators 130a at the top of the battery pack 110, and are arranged inside the phase change material radiators 130a S-shape, and then extending along the exterior of the battery pack 110 to the phase-change material radiator 130b at the bottom of the battery pack 110, and inside the phase-change material radiator 130b is arranged in an S-shape. Both ends of the heat dissipation pipe 1...

Embodiment 3

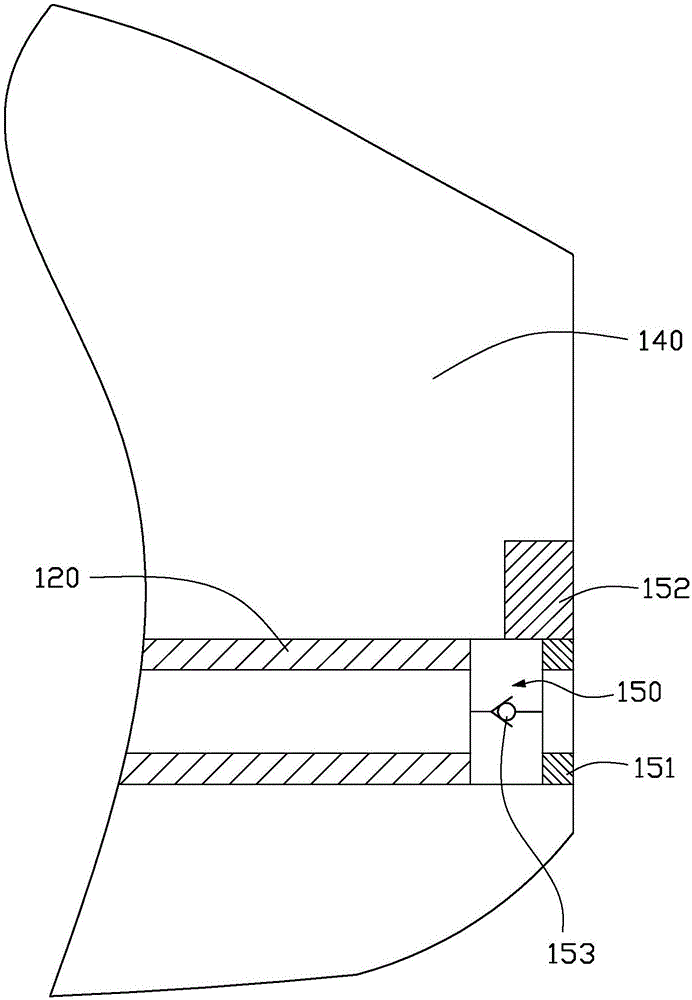

[0075] see Figure 10 , the present invention provides an electric vehicle 30 in another embodiment, the structure of the electric vehicle 30 is basically the same as that in the first embodiment. The difference is that the battery pack 110 is arranged at the rear of the electric vehicle, and the phase-change material radiators 130a and 130b are adhered to the top and bottom of the battery pack 110 at the same time, and there are two cooling pipes 120a and 130b respectively. 120b is embedded in the phase-change material radiators 130a and 130b, and the heat-dissipating pipes 120a and 120b are arranged as straight tubes inside the phase-change material radiators 130a and 130b respectively. Both ends of the heat dissipation pipes 120a and 120b respectively extend from the phase change material heat sinks 130a and 130b to the body 140 of the electric vehicle, and form a cooling liquid inlet 150 and a cooling liquid outlet 160 after being combined. The heat pipe 120 has a diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com