Method for designing high-vacuum freeze, sublimation, drying and pulverization integrated machine and its equipment

A technology of vacuum freezing and design method, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problem that the crushing of flammable and explosive materials is prone to sparks, it is difficult to meet the national GMP standard, and the finished product is reduced. Medicinal value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

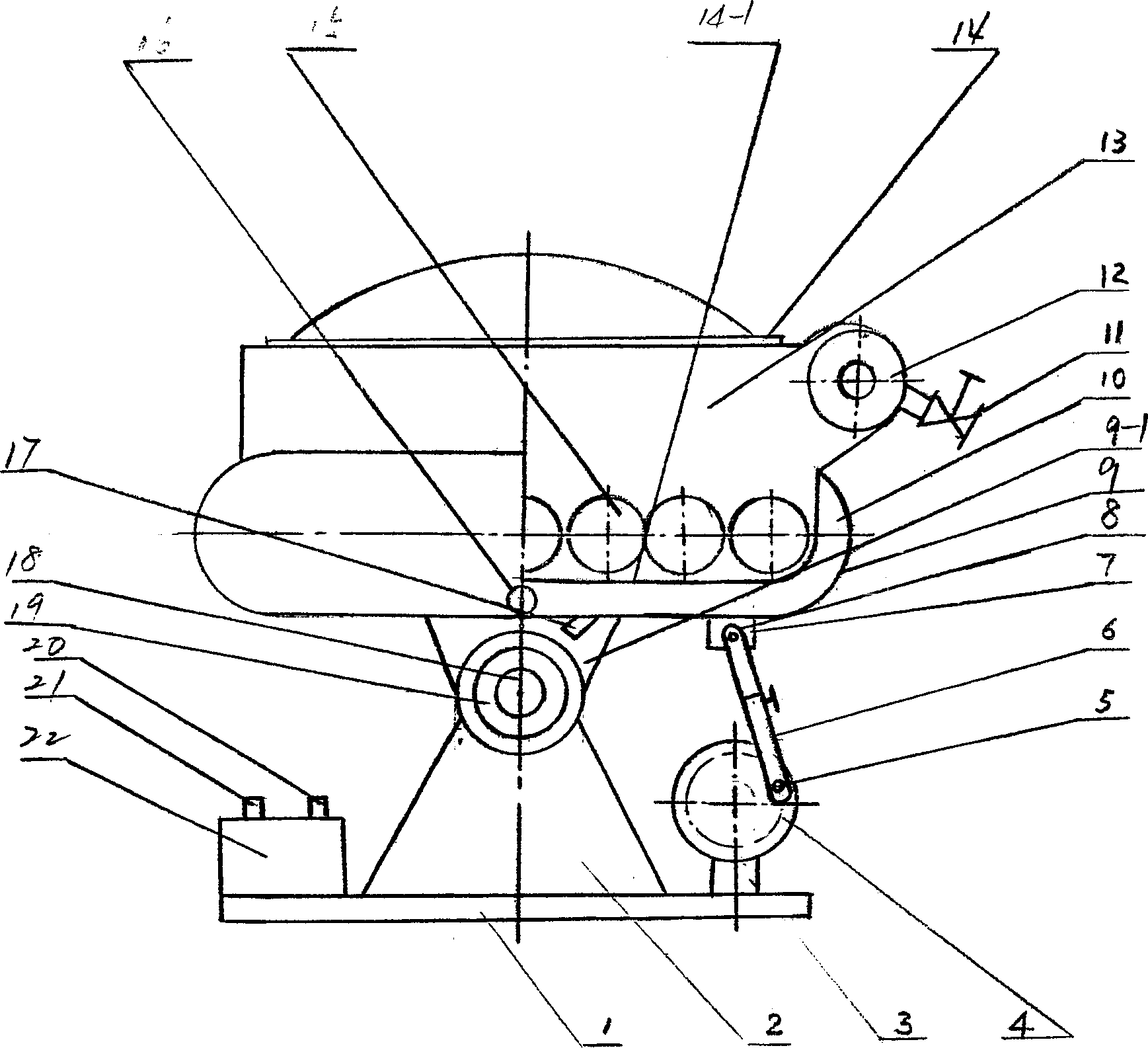

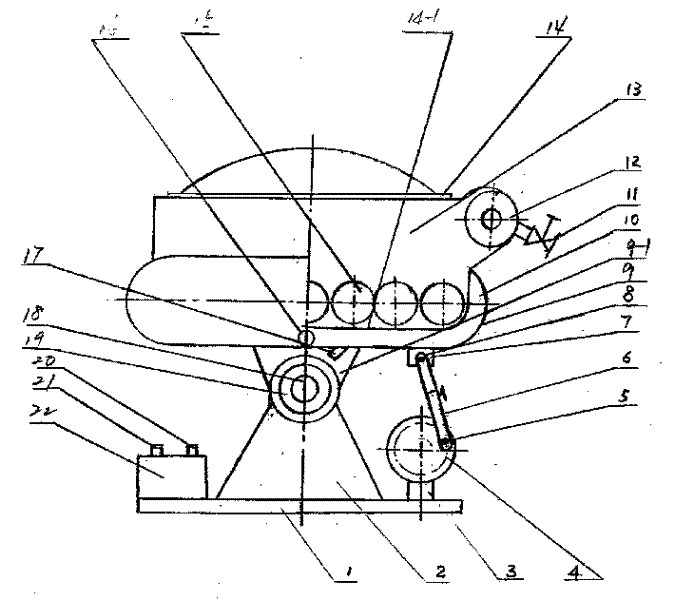

[0018] Below in conjunction with accompanying drawing, the present invention is further described with the high-vacuum freezing, sublimation, drying and pulverizing integrated machine of 7 grinding shaft rollers:

[0019] See accompanying drawing 1, there are inherently two bearing blocks 2 on the base 1, bearing blocks 2 are provided with bearings 19, the bearings 19 at the two ends are worn with grinding and swinging shaft rollers 18, and the grinding and oscillating shaft rollers 18 between the two bearing blocks 2 Through the matching hole of the swing arm 9-1 under the grinding cavity 9, the swing arm 9-1 is fixed with the grinding cavity 9, and one end of the bottom surface of the grinding cavity 9 is fixed with a bracket 8, and the pins 5, 7 , the swaying power unit 4 is flexibly connected to the bracket 8 through the telescopic link 6, the swaying power unit 4 is seated on the swaying power unit bracket 3, the swaying power unit bracket 3 is fixed on the base 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com