Screw press

A technology for screw presses and fuselages, applied in the field of presses, which can solve problems such as insufficient lubrication, wear, and shortened service life of thread pairs, and achieve the effects of improving lubrication conditions, prolonging service life, and increasing forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

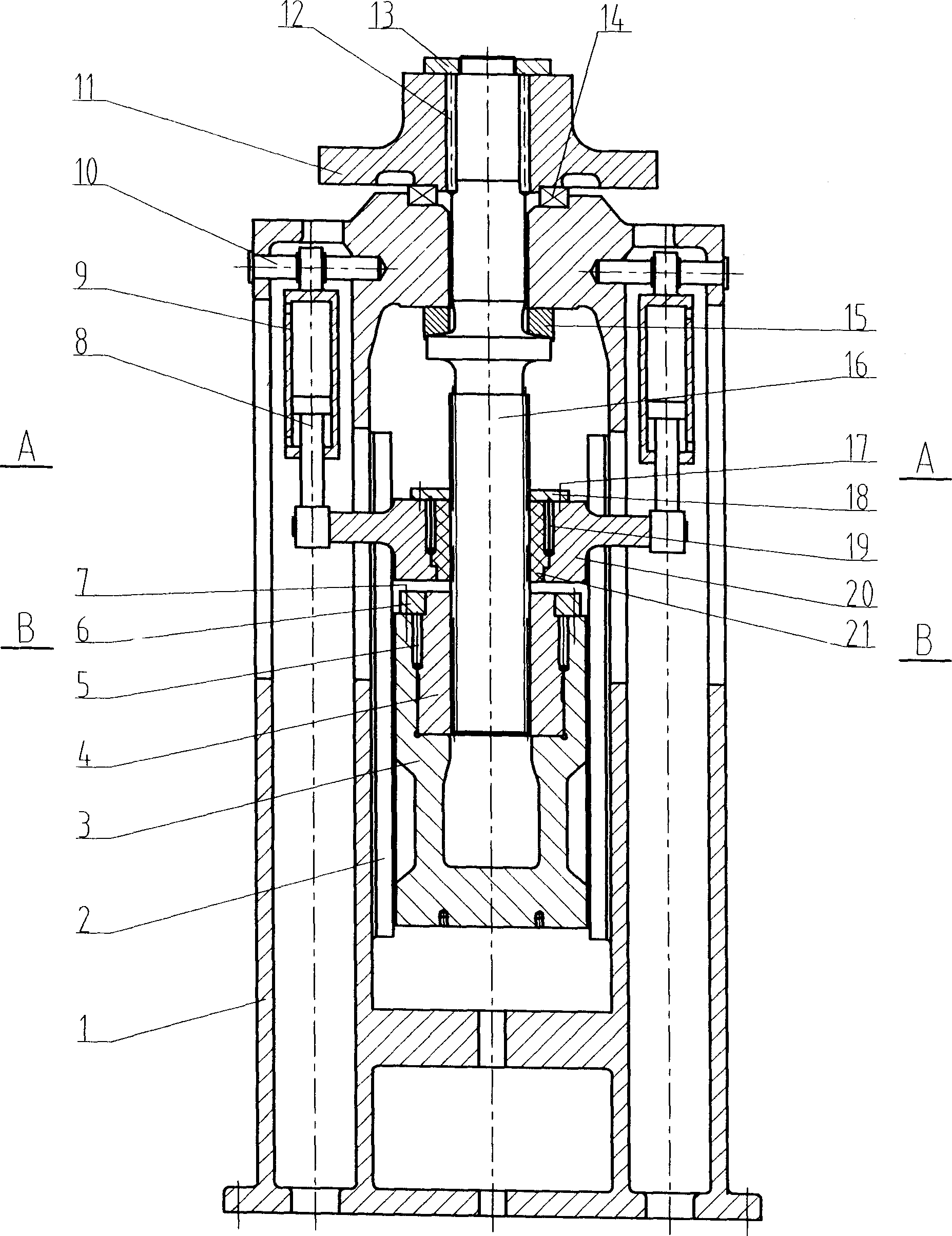

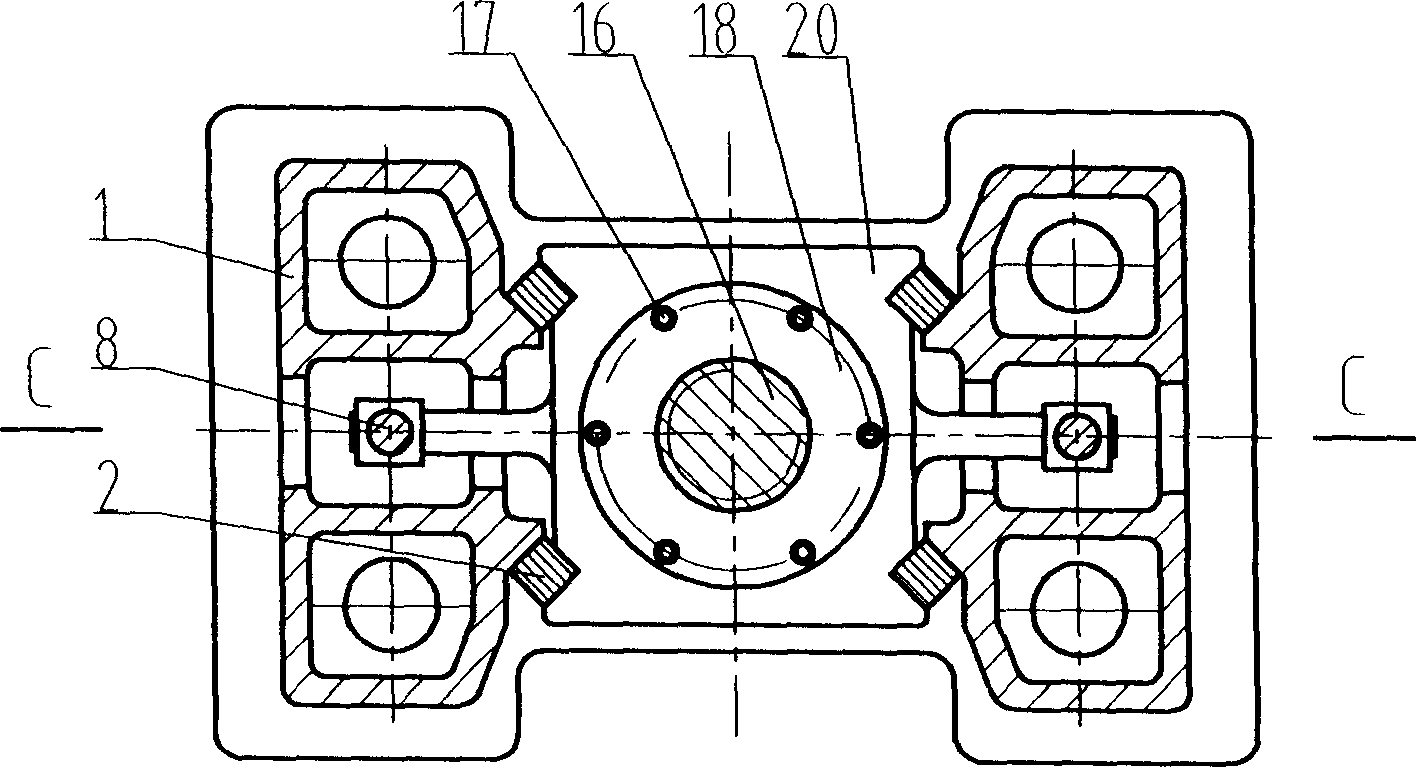

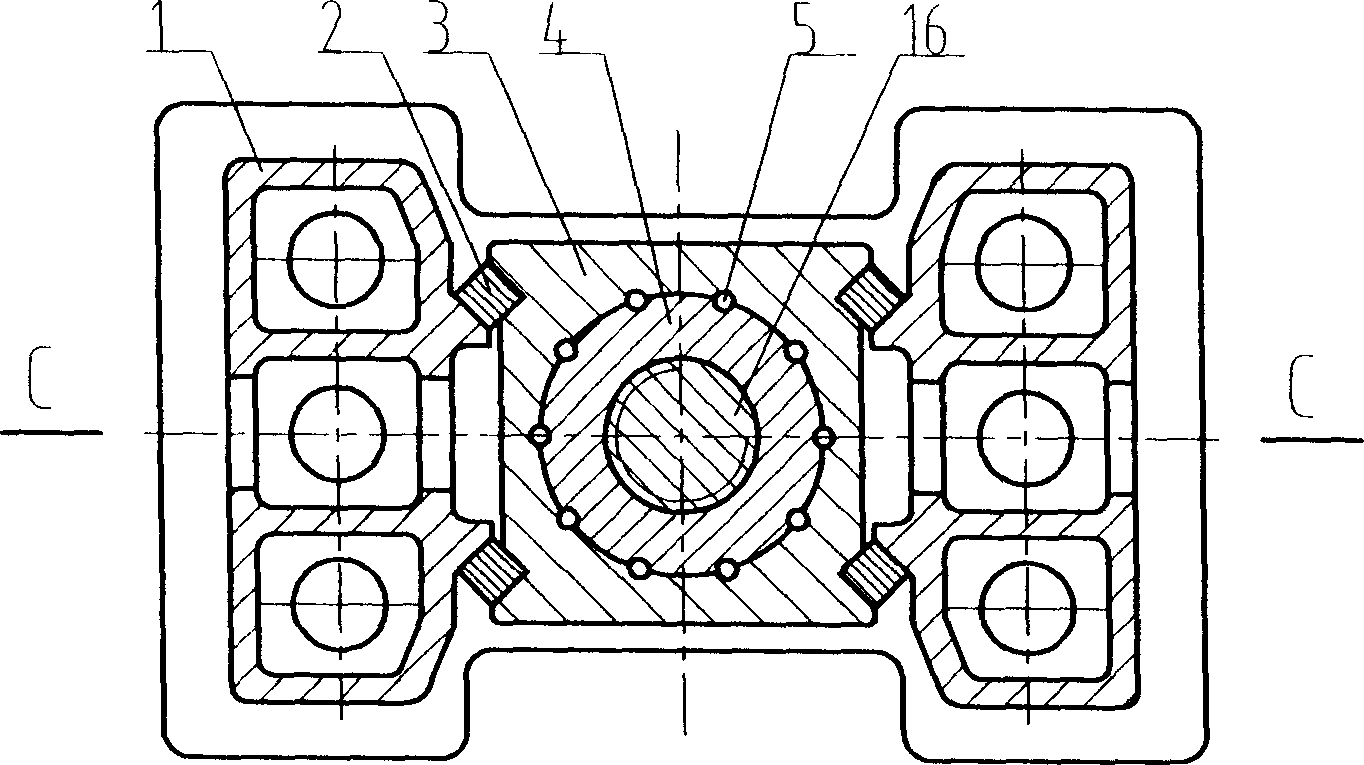

[0015] like figure 1 , figure 2 , image 3 As shown: four guide rails 2 are installed on the fuselage 1 of the screw press, and the main slider 3 and the auxiliary slider 20 can make reciprocating linear motion along the guide rails 2 . The main nut 4 is connected with the main slide block 3 as a whole through the main round pin 5, the main flange 6 and the main bolt 7, and the thread of the screw rod 16 is matched with the main nut 4. The auxiliary nut 21 is connected as a whole with the auxiliary slider 20 through the auxiliary round pin 19, the auxiliary flange 18 and the auxiliary bolt 17, and the thread of the screw rod 16 is matched with the auxiliary nut 21. The end of the piston rod 8 is hingedly connected with the auxiliary slider 20 , and the hydraulic cylinder 9 is installed on the fuselage 1 through the support pin 10 . The screw rod 16 is integrally connected with the inertia wheel 11 through the round pin 12 and the flat nut 13 , and is installed on the fusel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap