Device at axle head for blocking fiber fly

A kind of flying flower and shaft end technology, which is used in deburring devices, textile and papermaking, fiber processing, etc., can solve the problems of insecurity, high downtime, damage to card clothing, etc. Flying flowers, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

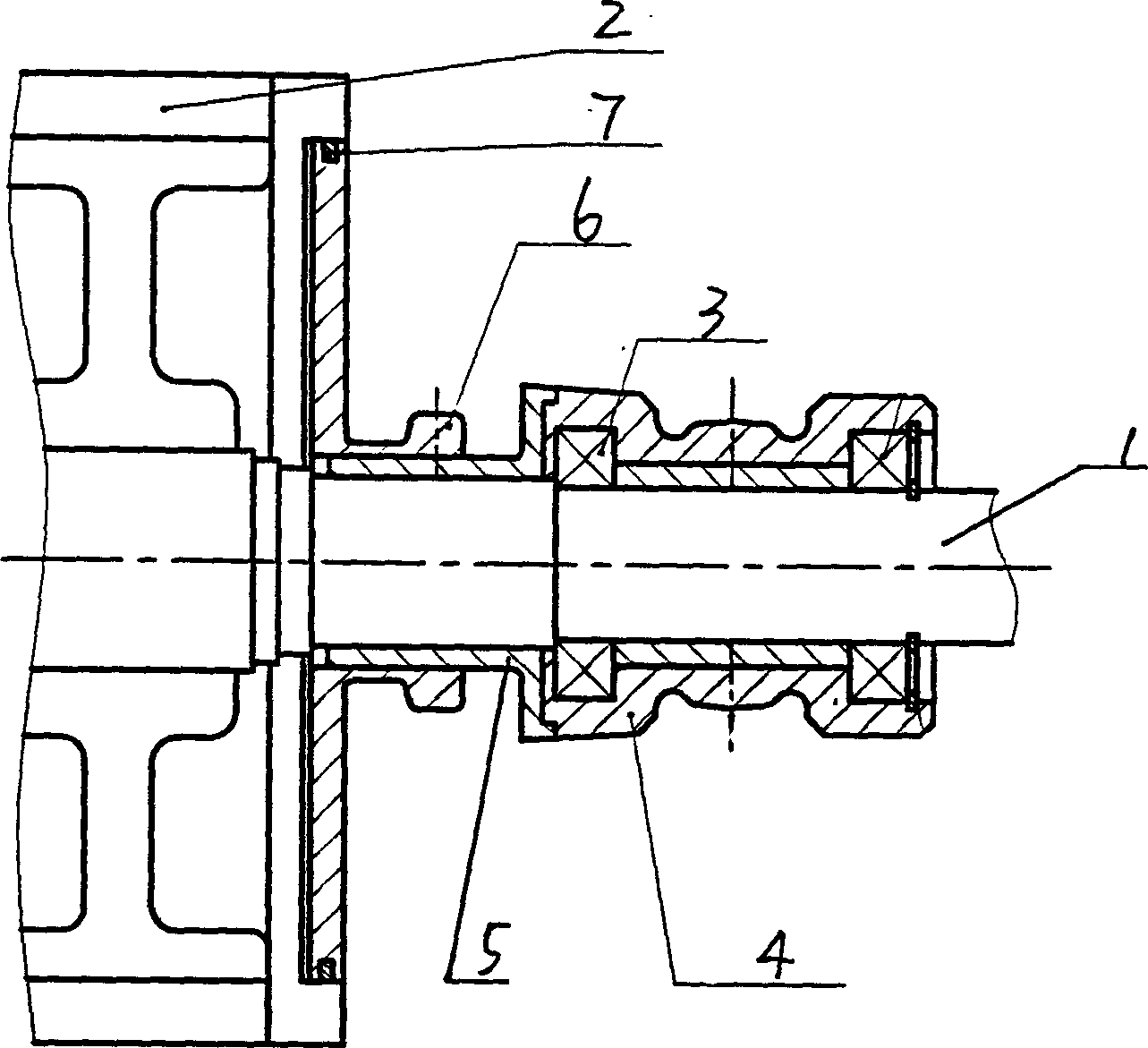

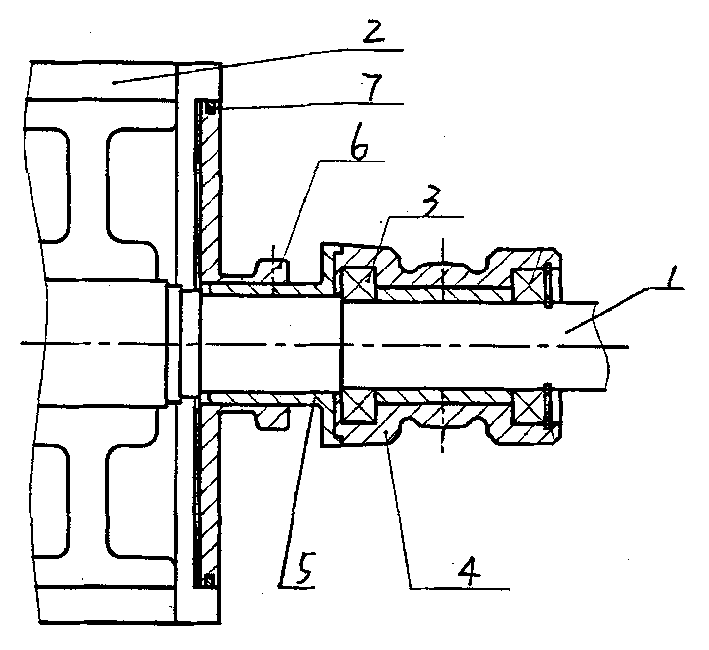

[0011] like figure 1 The shaft end flying flower device shown has a drum shaft 1, a drum 2 is arranged on the drum shaft 1, a bearing 3 is arranged at the end of the drum shaft 1, and the bearing 3 is fixed on the drum shaft 1 by a bearing seat 4, and the side of the drum 2 is opened. There is a concave part, and a shaft sleeve 5 is arranged between the end of the drum 2 on the drum shaft 1 and the end of the bearing seat 4 near the drum 2, and the adjustable bearing inner retaining ring 6 is arranged on the shaft sleeve 5, and the adjustable bearing inner The circular surface portion of the retaining ring 6 is arranged in the recess at the end of the drum 2 . A groove is formed on the circumferential surface of the adjustable bearing inner retaining ring 6 , and a felt ring 7 is provided on the circumferential surface of the recess at the end of the drum 2 and the groove of the adjustable bearing inner retaining ring 6 . The adjustable bearing inner retaining ring 6 is movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com