3D printing metal powder material manufacturing equipment

A technology of metal powder and 3D printing, which is applied in the field of 3D printing, can solve the problems that metal powder is easy to block in the screening hole and the screening hole is blocked, so as to solve the problem of flying around, better use effect and smooth flow sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

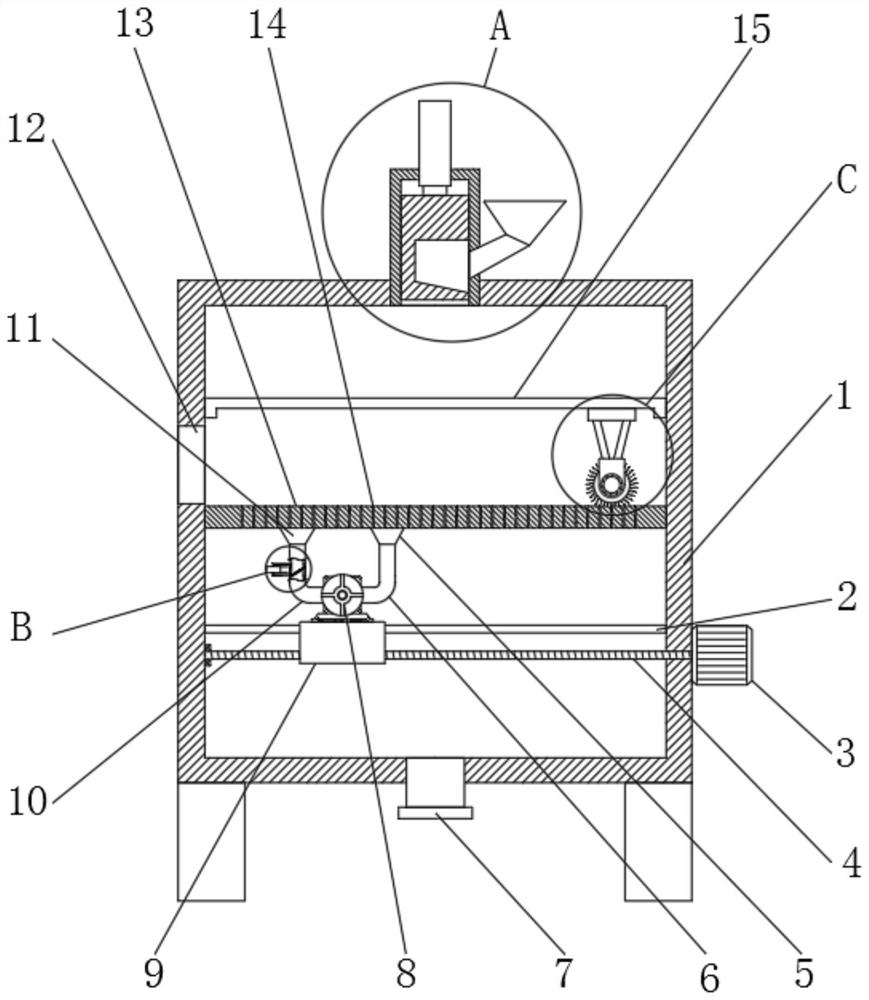

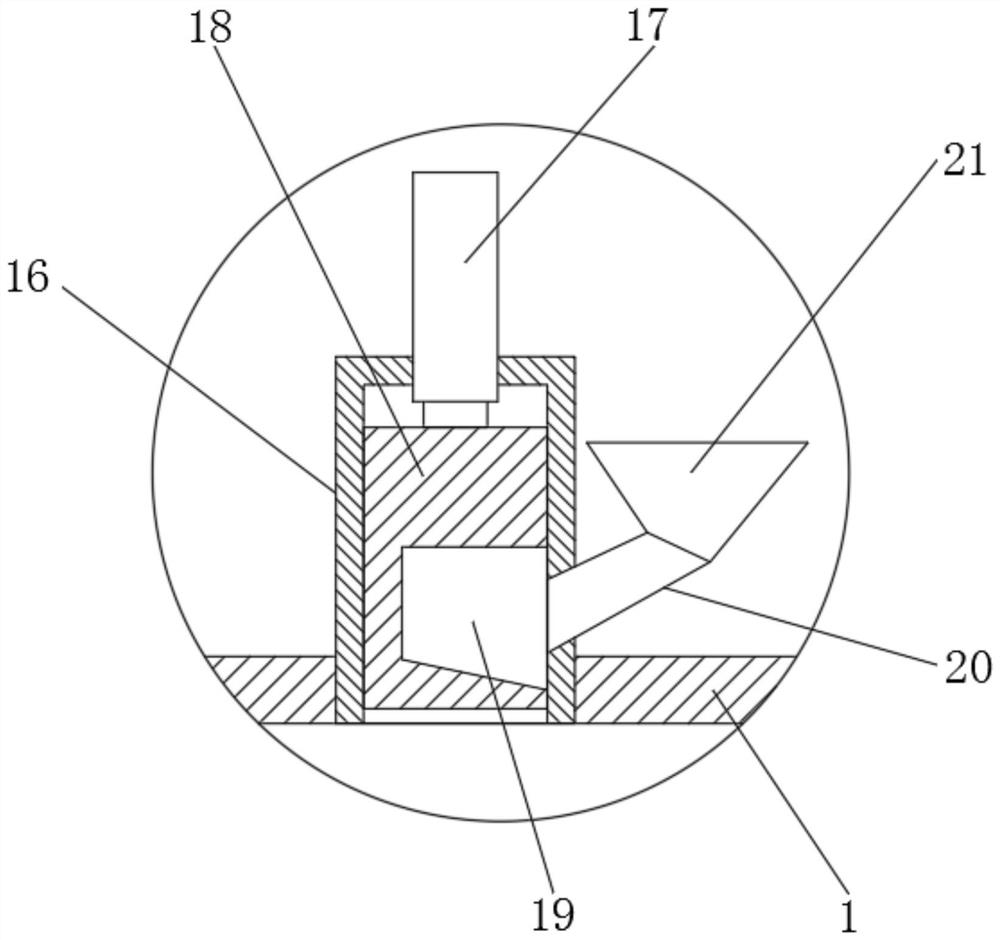

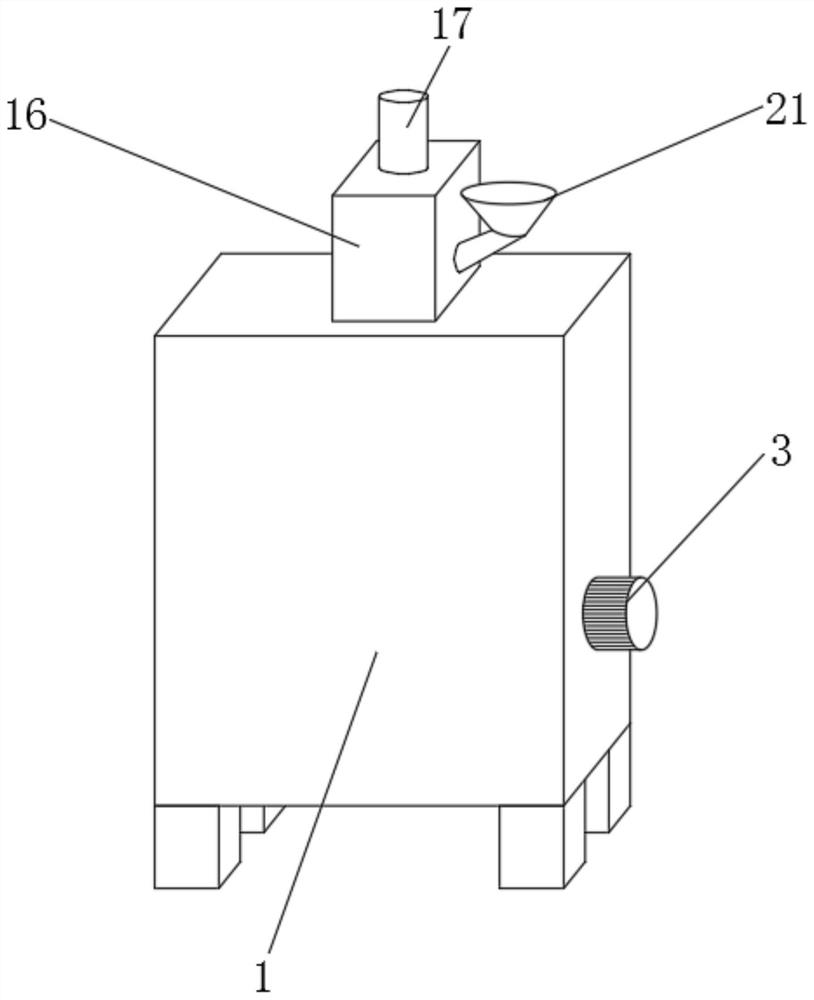

[0031] refer to Figure 1-5 , a 3D printing metal powder material manufacturing equipment, including a processing box 1, the top outer wall of the processing box 1 is provided with a feeding mechanism, the inner wall of the processing box 1 is provided with a sieve plate 13, and the top outer wall of the sieve plate 13 is provided with a plurality of Screening holes 14, a first motor 3 is arranged on one side outer wall of the processing box 1, and one end of the output shaft of the first motor 3 is provided with a screw rod 4, the outer wall thread of the screw rod 4 is provided with a movable block 9, and the inner wall of the processing box 1 is provided with There is a fixed rod 2, and the movable block 9 is slidably arranged on the fixed rod 2. The top outer wall of the movable block 9 is fixedly connected with a fan 8, and the exhaust end of the fan 8 is connected with an exhaust hood 11 through an exhaust pipe 10, and the air guide of the fan 8 End is connected with win...

Embodiment 2

[0040] refer to Figure 6 , a 3D printing metal powder material manufacturing equipment. Compared with Embodiment 1, this embodiment also includes that the inner walls on both sides of the processing box 1 are fixedly connected with material blocking plates 33 .

[0041] Working principle: when in use, the material blocking plate 33 can prevent metal powders from accumulating in the dead corners around the processing box 1 and cause difficulty in discharge, and the use effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com