Integrated lamp optical system and projector with the system

An illumination optical system and integral technology, applied in the field of integral illumination optical system, can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

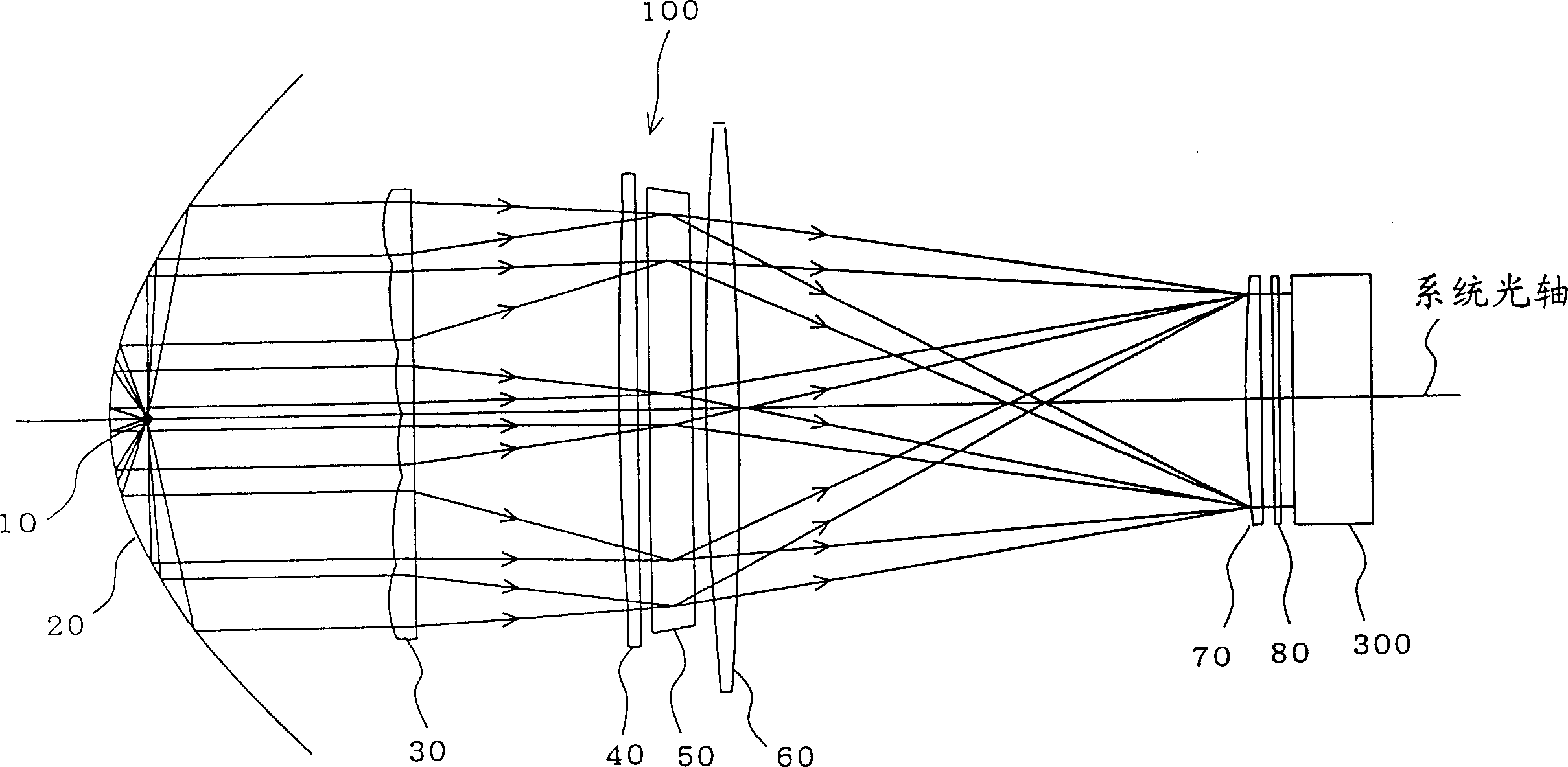

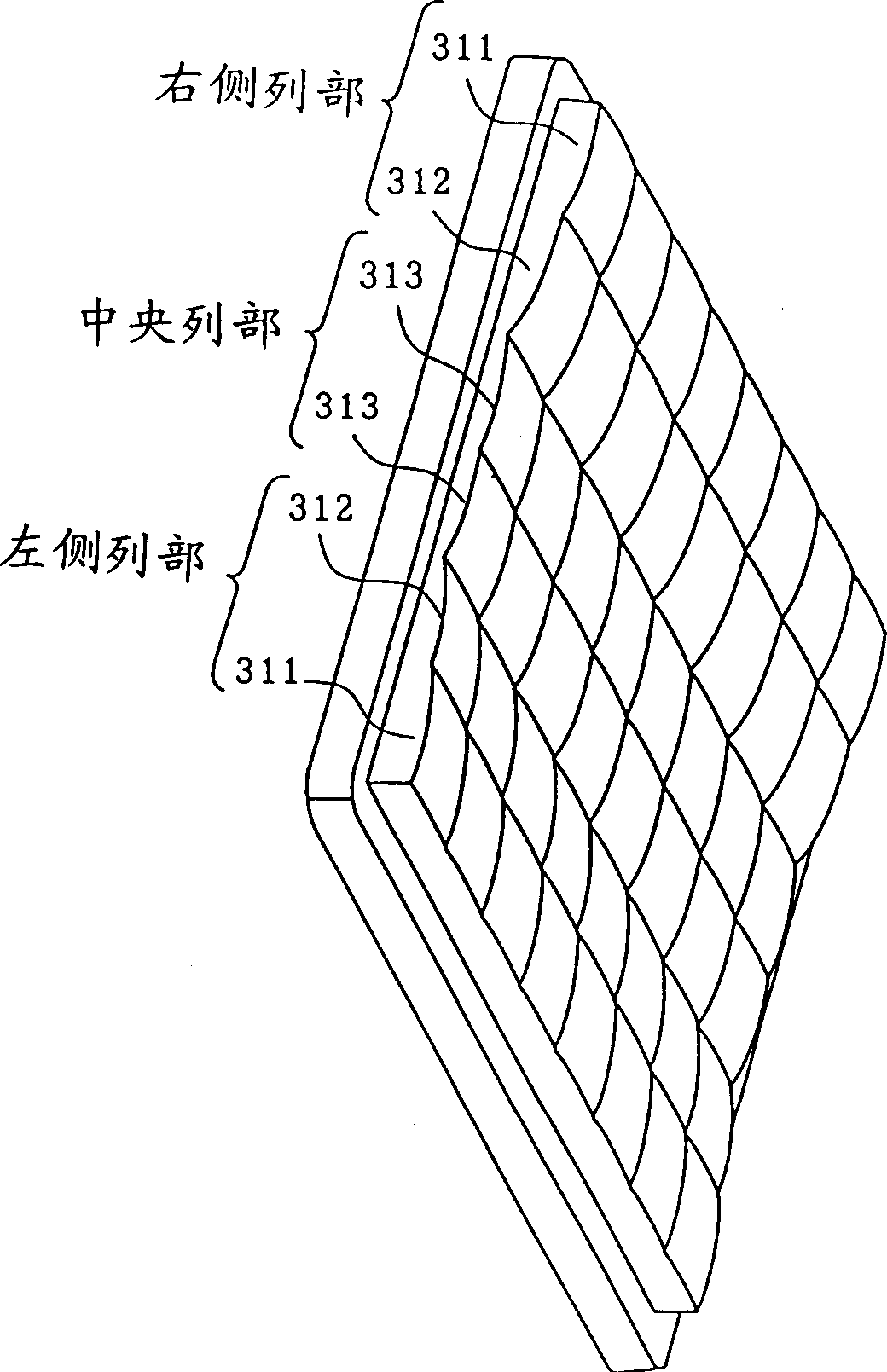

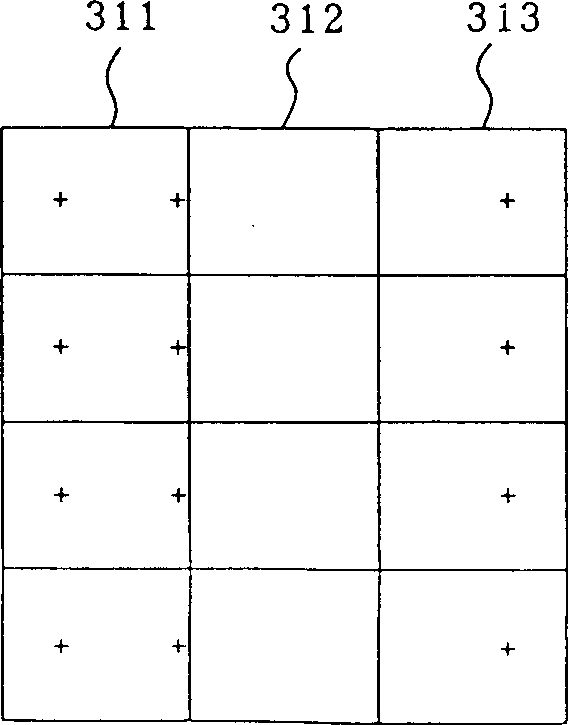

[0022] figure 1 It is an explanatory diagram of the structure and action of the integral illumination optical system according to the embodiment of the present invention, figure 2 is showing figure 1 A perspective view of the shape of the first lens array in, image 3 It is a front view showing the optical axis position of each lens unit constituting the first lens array, Figure 4 is showing figure 1 A perspective view of the shape of the second lens array in, Figure 5 is a front view showing the optical axis position of each lens unit constituting the second lens array, Image 6 is a front view of the light source image formed on the polarization conversion element 50 condensed by the first lens array, Figure 7 is showing figure 1 A perspective view of the structure of the polarization conversion element in Fig.

[0023] The integral illumination optical system 100 of the present embodiment, such as figure 1 As shown in , it includes: a lamp 10 as a light sou...

Embodiment approach 2

[0035] Next, an embodiment of a projector including the above-described integral illumination optical system 100 will be described. The projector of this embodiment, such as Figure 8 As shown in the optical system structure diagram, it is composed of the following parts: integral illumination optical system 100; color light separation optical system 200; liquid crystal panel 300 (300R, 300G, 300B); cross dichroic prism 400; and projection lens 500.

[0036] The color light separation optical system 200 includes first and second dichroic mirrors 201 and 202 , and separates light emitted from the illumination optical system 100 into three color lights of red, green, and blue. The first dichroic mirror 201 transmits the red light component of the light emitted from the illumination optical system 100 , and reflects blue light and green light components. The red light transmitted through the first dichroic mirror 201 is reflected by the reflection mirror 211 , passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com