Ultrahigh pressure mercury lamp

A mercury lamp, ultra-high voltage technology, applied in the direction of high-pressure discharge lamps, discharge lamps, gas discharge lamps, etc., can solve the problems of unevaporated mercury, unstable arc, shortened service life, etc., to suppress blackening and devitrification, Good service life characteristics, the effect of securing the initial beam quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

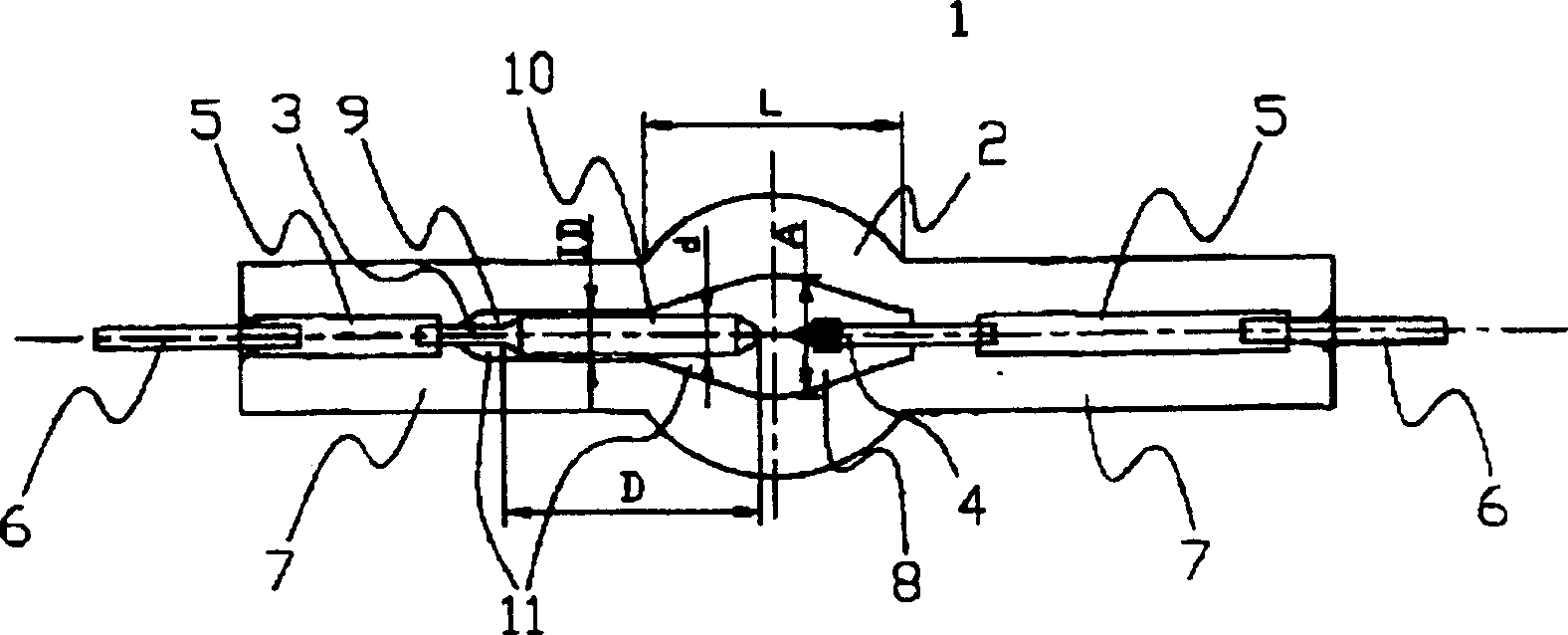

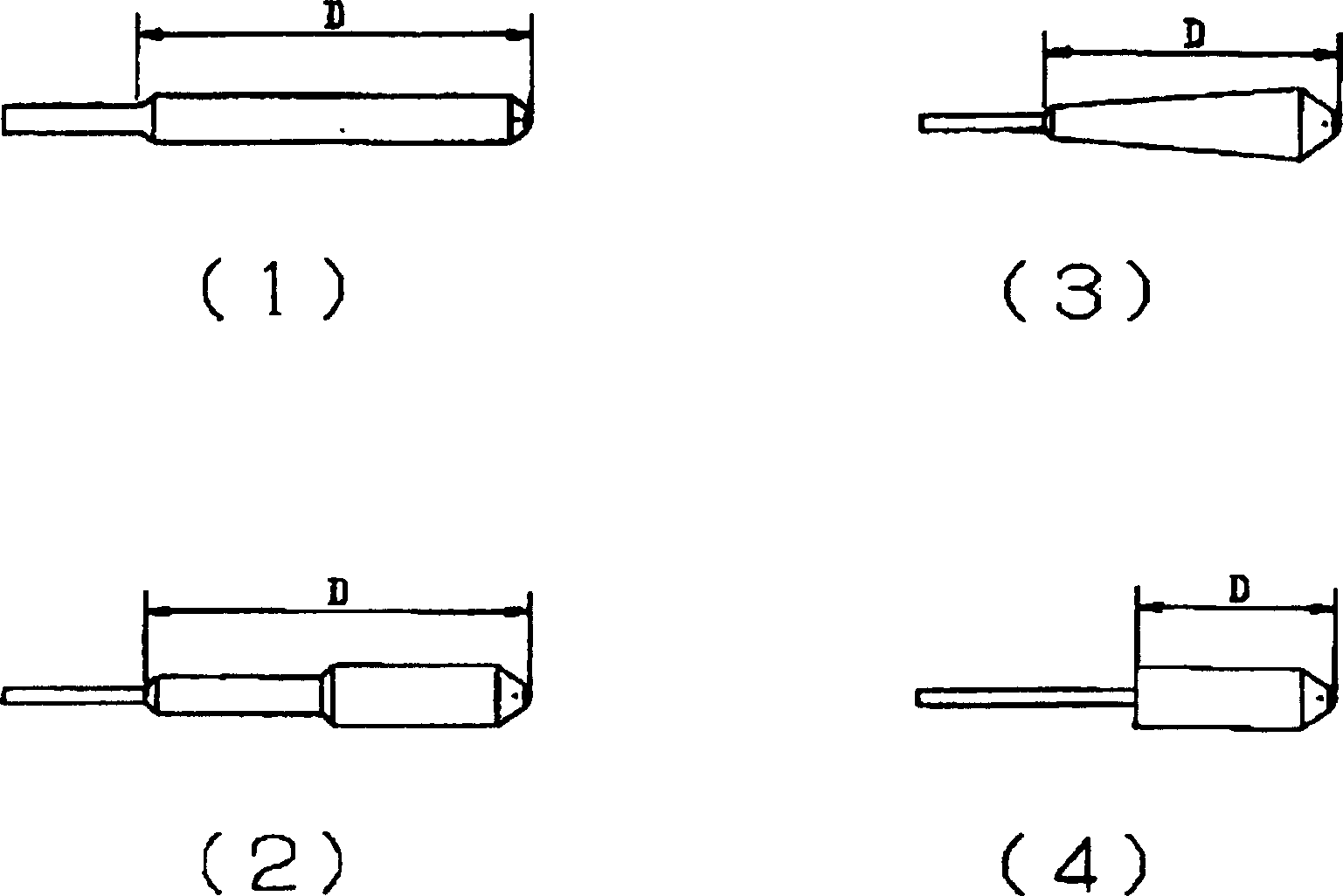

[0035] Embodiments of the present invention will be described below. figure 1 It is the first embodiment of the ultra-high pressure mercury discharge lamp of the present invention. The bulb portion 2 of this ultra-high pressure mercury discharge lamp 1 is an approximately ellipsoidal body made of quartz. Inside the bulb portion 2, an anode 3 and a cathode 4 made of tungsten are arranged at a distance between electrodes of 1.0 mm. A metal foil 5 such as molybdenum is welded to the rear ends of the electrodes 3 and 4 , and an external lead 6 is connected to the other end of the metal foil 5 .

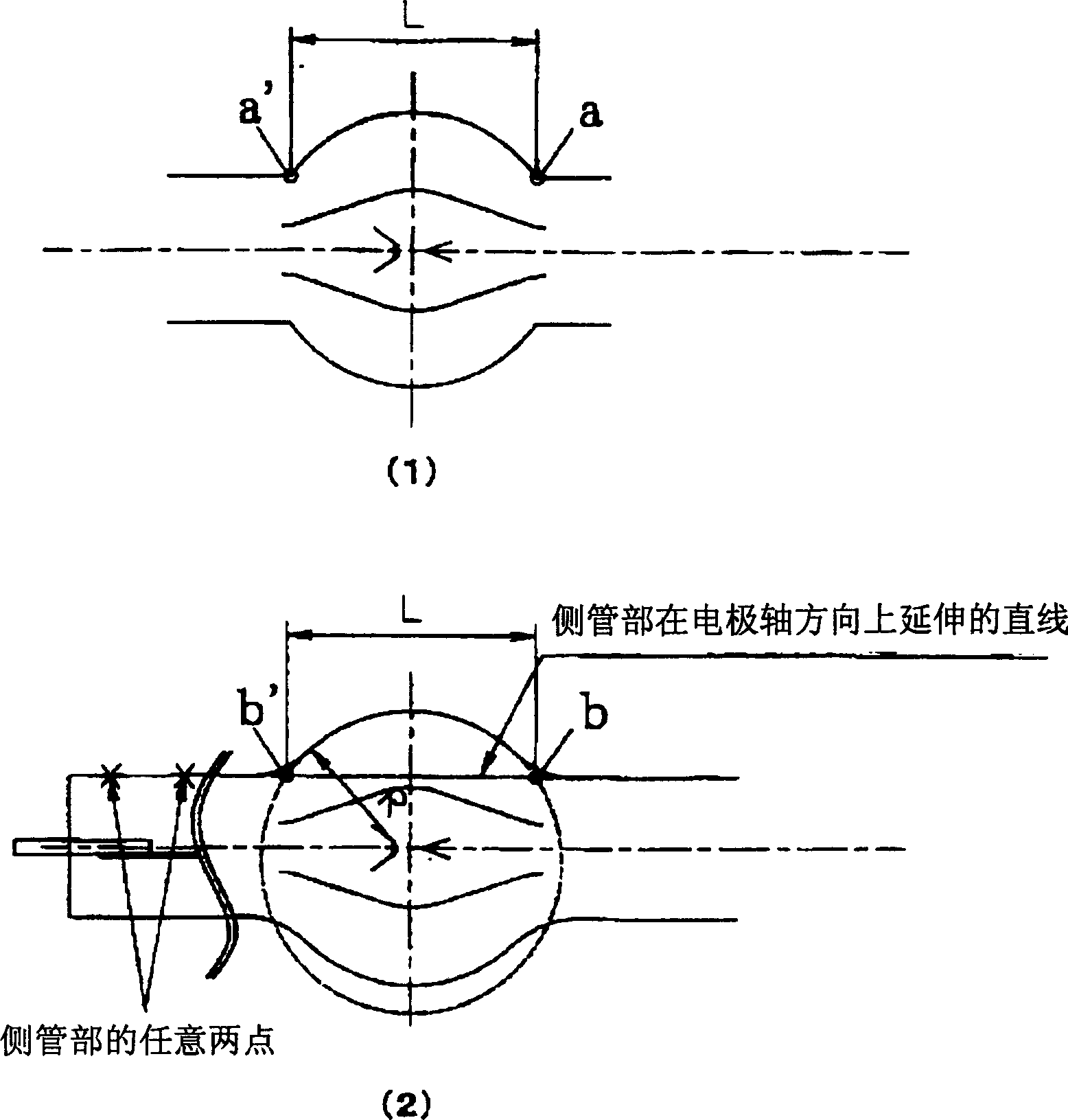

[0036] The maximum inner diameter A of the lamp tube of the lamp tube means the maximum inner diameter of the lamp tube in the direction perpendicular to the tube axis connecting the electrodes, and the maximum inner diameter A of the lamp tube is 4.8mm. In addition, the lamp tube length L in the tube axis direction of the tube portion 2 having a substantially ellipsoidal shape is 10.2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap