Automatic scale cleaning method for electric heating tube in electric water heater

An electric water heater, automatic cleaning technology, applied in the direction of deformation cleaning, combustion cleaning, cleaning heat transfer devices, etc., can solve the problems of shortening the service life of electric heating tubes, wasting resources, burning electric heating tubes, etc., to ensure heat exchange efficiency and prolong use Longevity and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A method for automatically removing scale from an electric heating tube in an electric water heater.

[0029] There is a clock in the controller; the controller has a preset time setting value for removing scale at 3 o'clock in the morning on the first day of each quarter every year; when the clock runs to 3 o'clock in the morning on the first day of each quarter, the controller will The following descaling work:

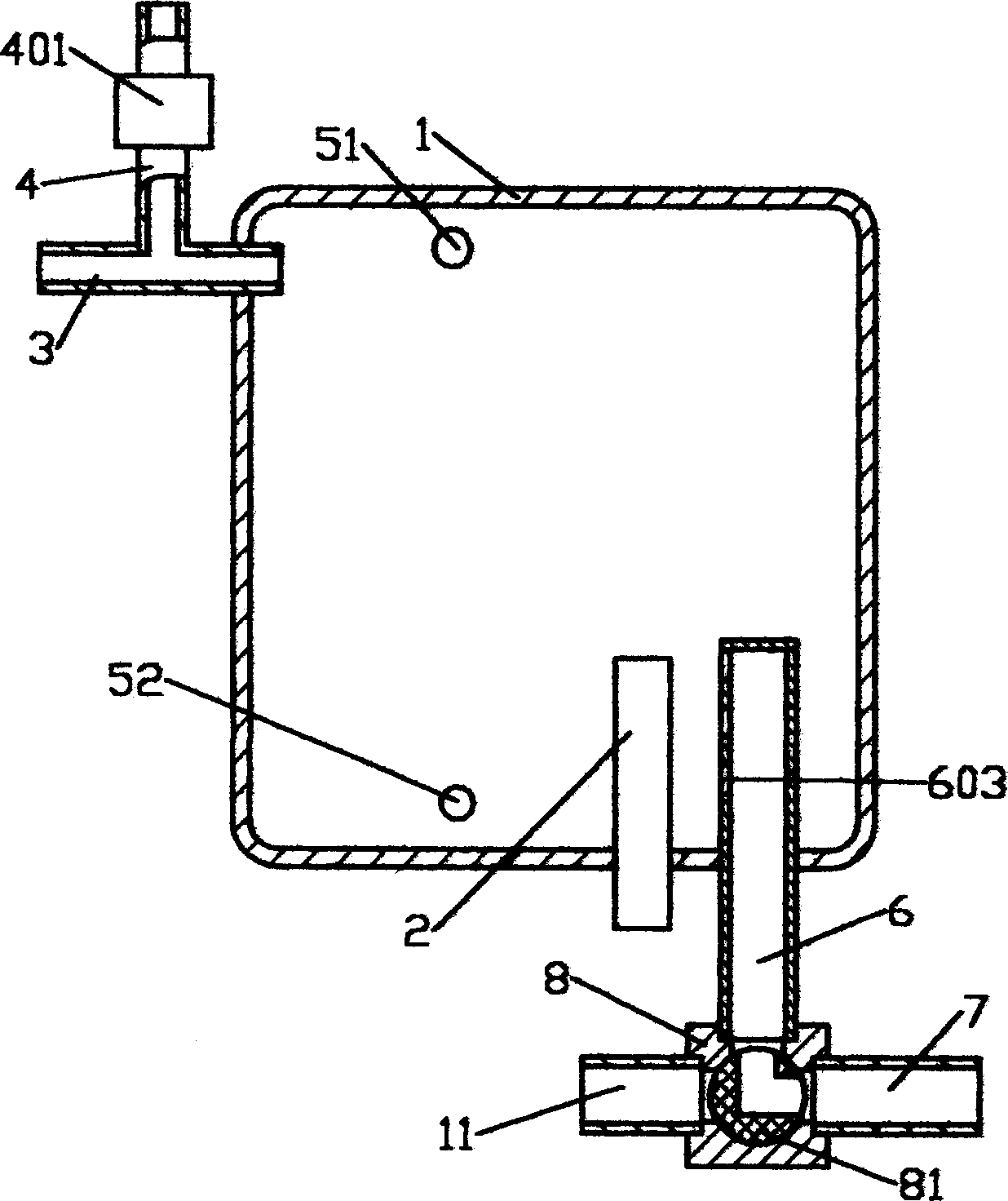

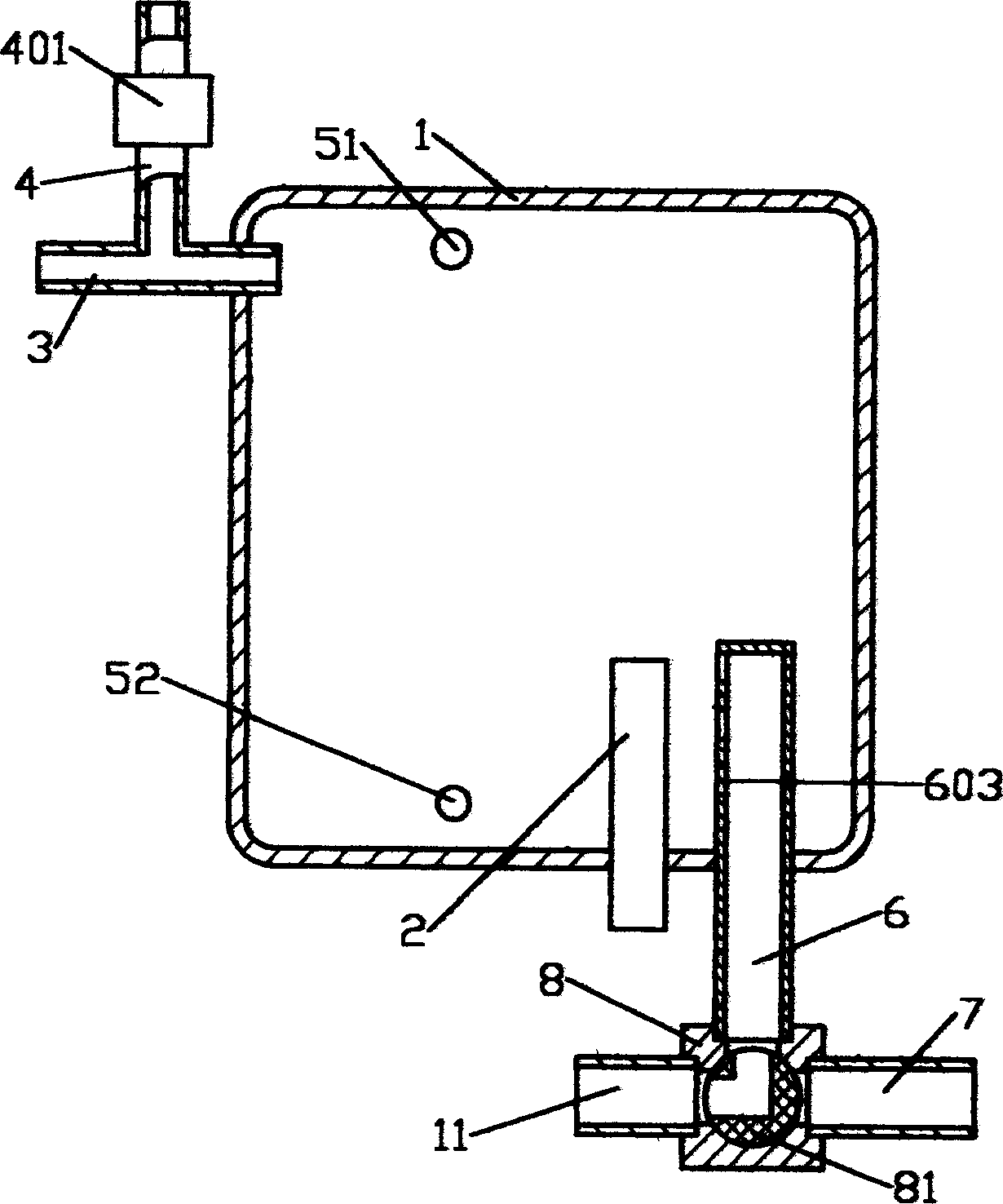

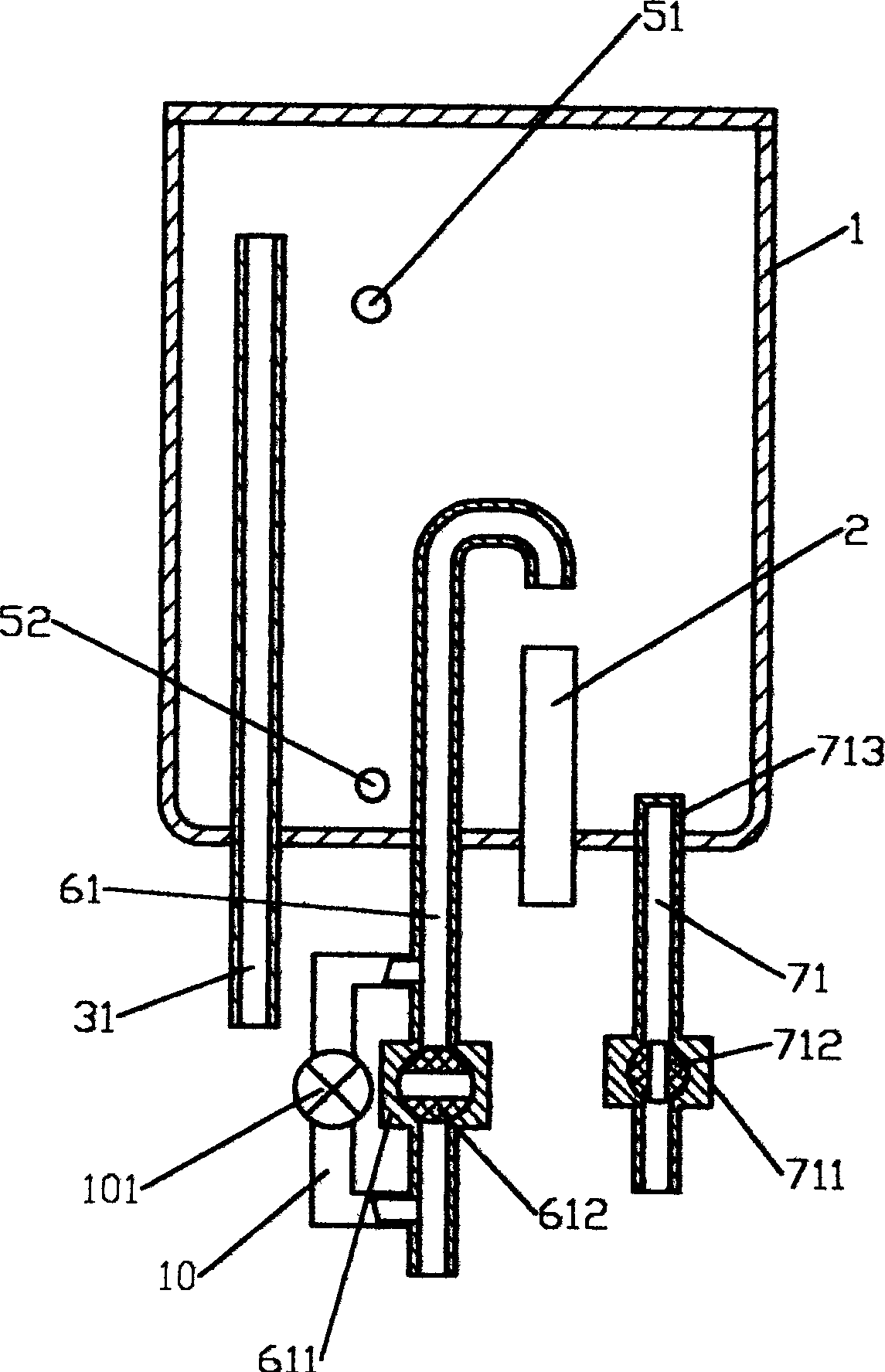

[0030] In the first step, the controller opens the electric control valve 401 on the balance air pipe 4 so that the water tank 1 communicates with the atmosphere, and at the same time controls the two-position three-way electric control valve at the station two (such as figure 1 ), the water in the water tank 1 is discharged through the side hole 603, the water inlet pipe 6 and the drain pipe 7, and when the water level drops to the sensing position of the low water level sensor, the electric heating tube has been exposed to the air in the water...

Embodiment 2

[0034] Embodiment 2: A method for automatically removing scale from an electric heating tube in an electric water heater.

[0035] The controller is equipped with an accumulative timer for the electric water heater; the controller is equipped with a set value when the accumulative working time of the electric water heater reaches 100 days; when the counting value of the timer reaches 100 days, the controller performs the following work of removing scale :

[0036] In the first step, the controller opens the electric control valve 401 on the balance air pipe 4 so that the water tank 1 communicates with the atmosphere, and at the same time controls the two-position three-way electric control valve at the station two (such as figure 1 ), the water in the water tank 1 is discharged through the side hole 603, the water inlet pipe 6 and the drain pipe 7, and when the water level drops to the sensing position of the low water level sensor, the electric heating tube has been exposed to ...

Embodiment 3

[0041] Embodiment 3: A method for automatically removing scale from an electric heating tube in an electric water heater.

[0042] The controller is equipped with an accumulative timer for the electric heating tube of the electric water heater; the controller sets the cumulative working time of the electric heating tube to 100 hours as the set value; when the timer value reaches 100 hours, the controller performs the following steps to remove scale operate:

[0043] Step 1: The controller resets the working accumulation timer of the electric heating tube of the electric water heater;

[0044] In the second step, the controller opens the electric control valve 401 on the balance air pipe 4 to make the water tank 1 communicate with the atmosphere, and simultaneously controls the two-position three-way electric control valve to the station two (such as figure 1 ), the water in the water tank 1 is discharged through the side hole 603, the water inlet pipe 6 and the drain pipe 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com