Rocket power assisted launcher and its method

A launcher and booster technology, which is applied in the field of rocket-assisted launchers, can solve the problems of high cost and low rocket carrying capacity, and achieve the effects of reducing launch costs, saving fuel consumption, and avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

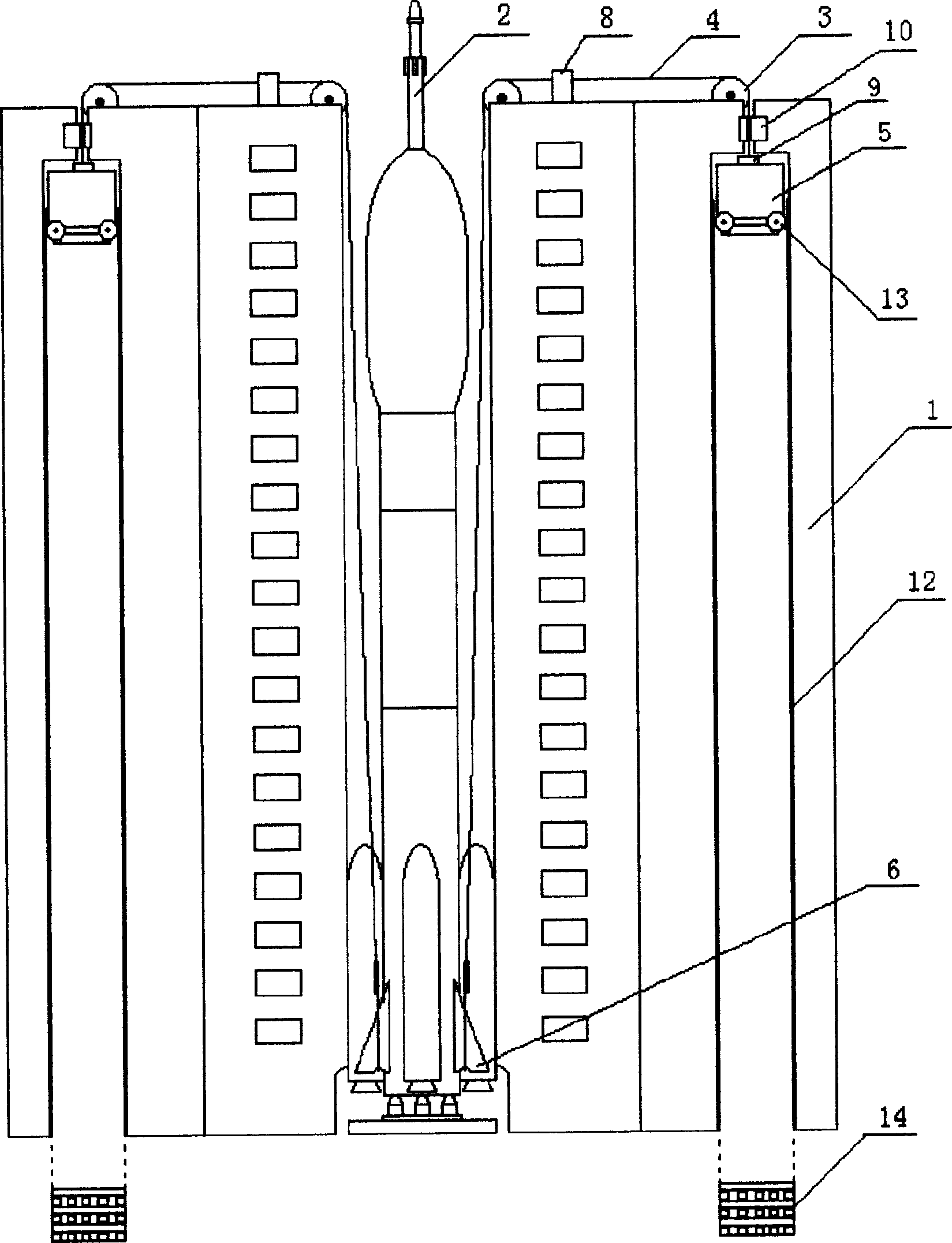

[0025] The following is a further explanation in conjunction with the drawings:

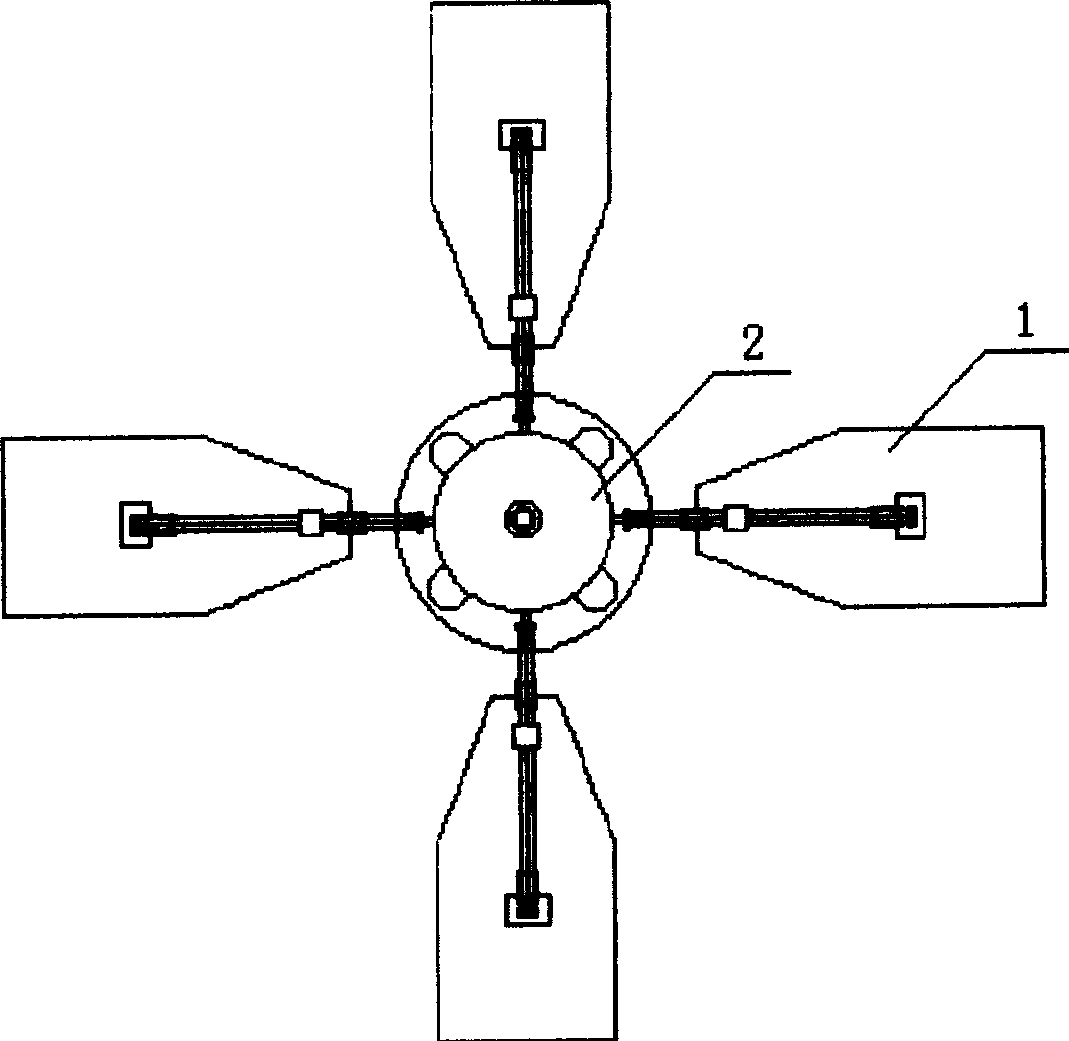

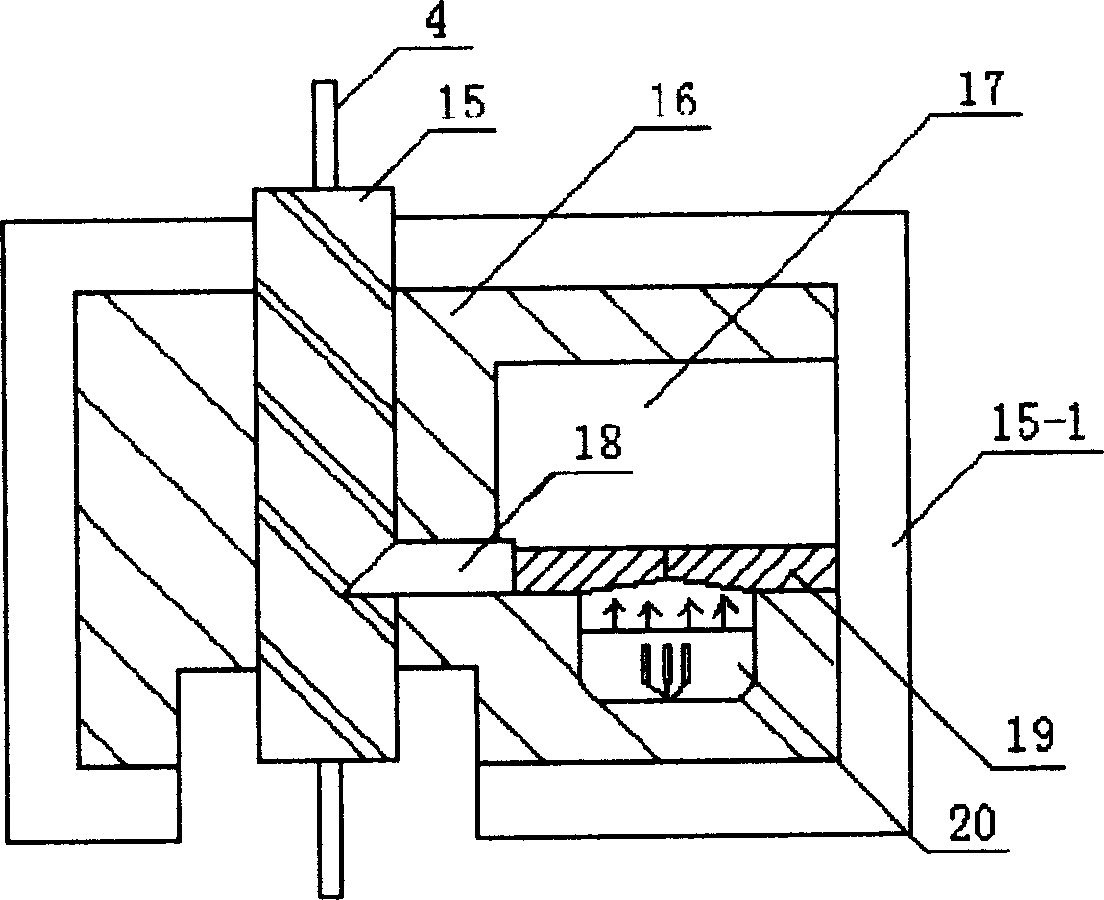

[0026] The first embodiment. The rocket booster launching device of the present invention includes a launching stand 1 and a rocket 2 located inside the launching stand 1, which is also equipped with a boosting device. The boosting device is a wire rope that is equipped with two fixed pulleys 3 on the top of the launching stand 1 and bypasses the fixed pulleys 3. One end of 4 is connected to a weight body 5 that can fall along the vertical track 12, and the weight body 5 is equipped with a guide wheel 13 that matches the vertical track 12. The other end of the wire rope 4 is connected to the rocket body in a detachable manner. The rocket 2 wire rope 4 After the weight body 5 is connected, the weight body 5 is located at the top dead center of the upper part of the launch frame 1. There are three wire ropes 4 in parallel, and the launching frame 1 is all located on the ground. The connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com