Rotary working table of rotary reflector type distribution photometer

A technology of goniophotometer and rotary table, which is applied in the direction of photometry, optical radiation measurement, measuring device, etc., can solve the problems affecting the measurement accuracy, and achieve the effect of high measurement accuracy and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

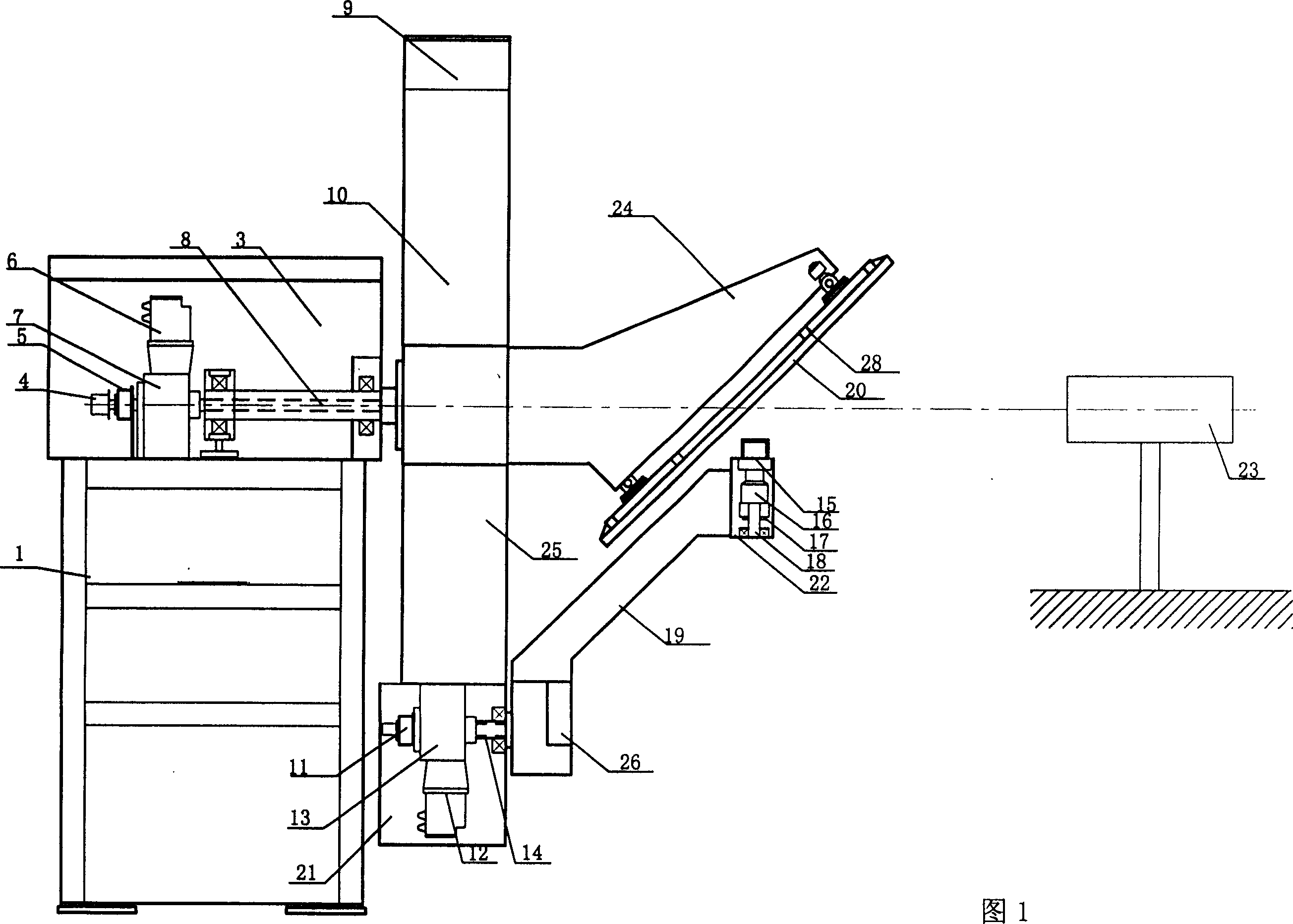

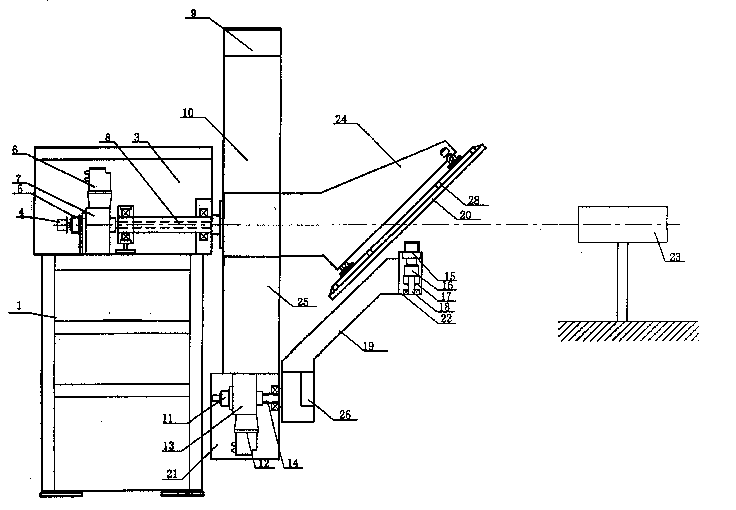

[0011] With reference to Fig. 1, the rotary table of the rotating mirror type goniophotometer of the present invention comprises base 1, is fixed on the main shaft drive box 3 on the base 1, utilizes bearing support to be installed with horizontal main shaft 8 in the main shaft drive box 3, here For example, the main shaft 8 adopts a hollow shaft, and a conductive slip ring 5 and a goniometer 4 for detecting the rotation angle are installed on the hollow shaft. The main shaft 8 is driven to rotate by a motor 6 with a reducer 7 placed in the box. Go out on the flange of the main shaft 8 end faces of driving box 3 and be fastened with boom 25 and cantilever 24, boom 25 is perpendicular to main shaft 8, and the centerline of cantilever 24 coincides with the axis of main shaft 8. The other end of the cantilever 24 is fixed with a reflector frame 28, and the mirror surface of the reflector 20 installed on the reflector frame forms an angle of 45 degrees with the axis of the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com