Hot air removable nozzle

A technology of hot air and nozzles, applied in the direction of elastic/clamping devices, assembly of printed circuits with electrical components, circuit layout on support structures, etc., can solve problems such as low operating efficiency, difficulty in determining the position of nozzle brackets, and time-consuming, etc. To achieve the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

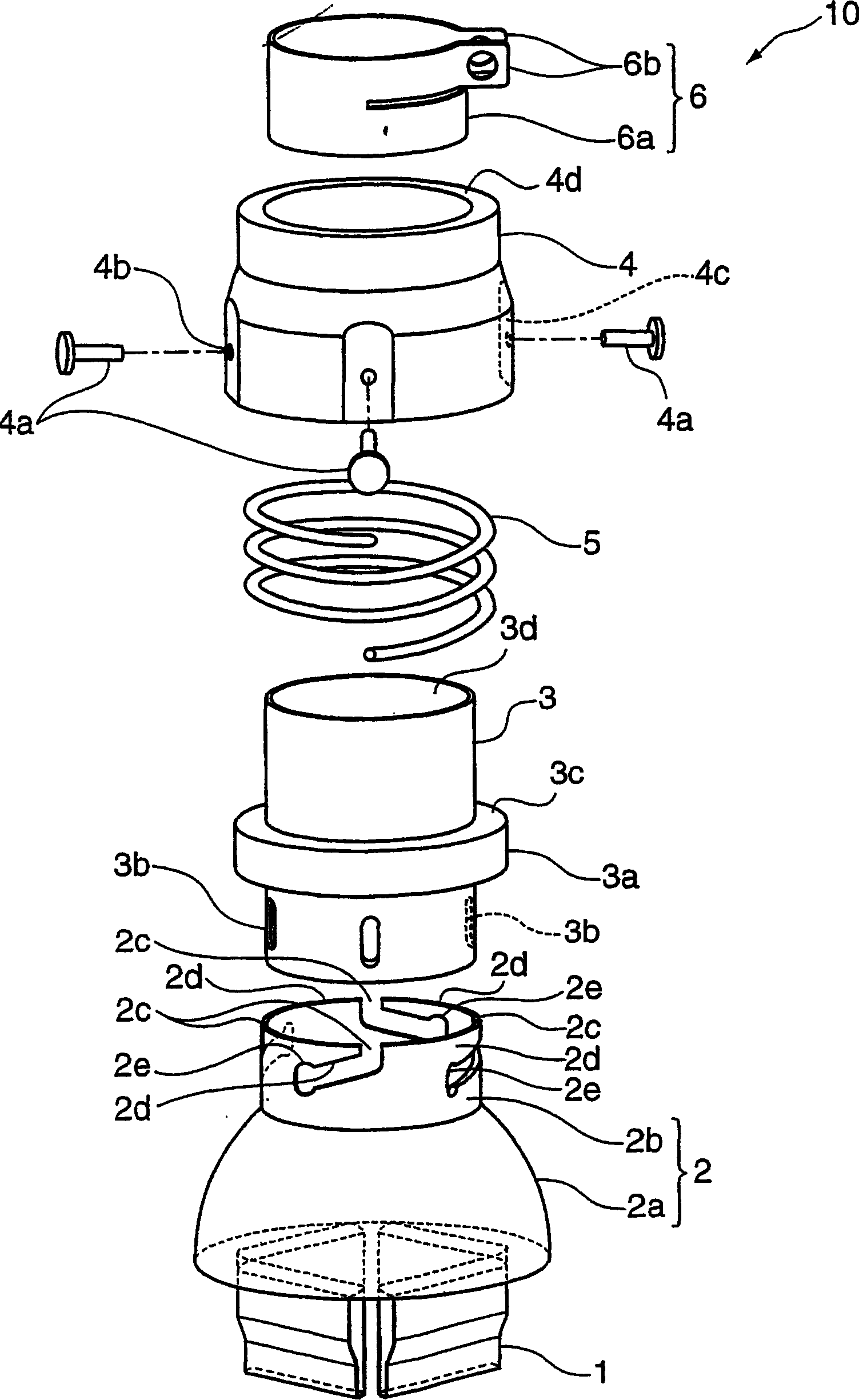

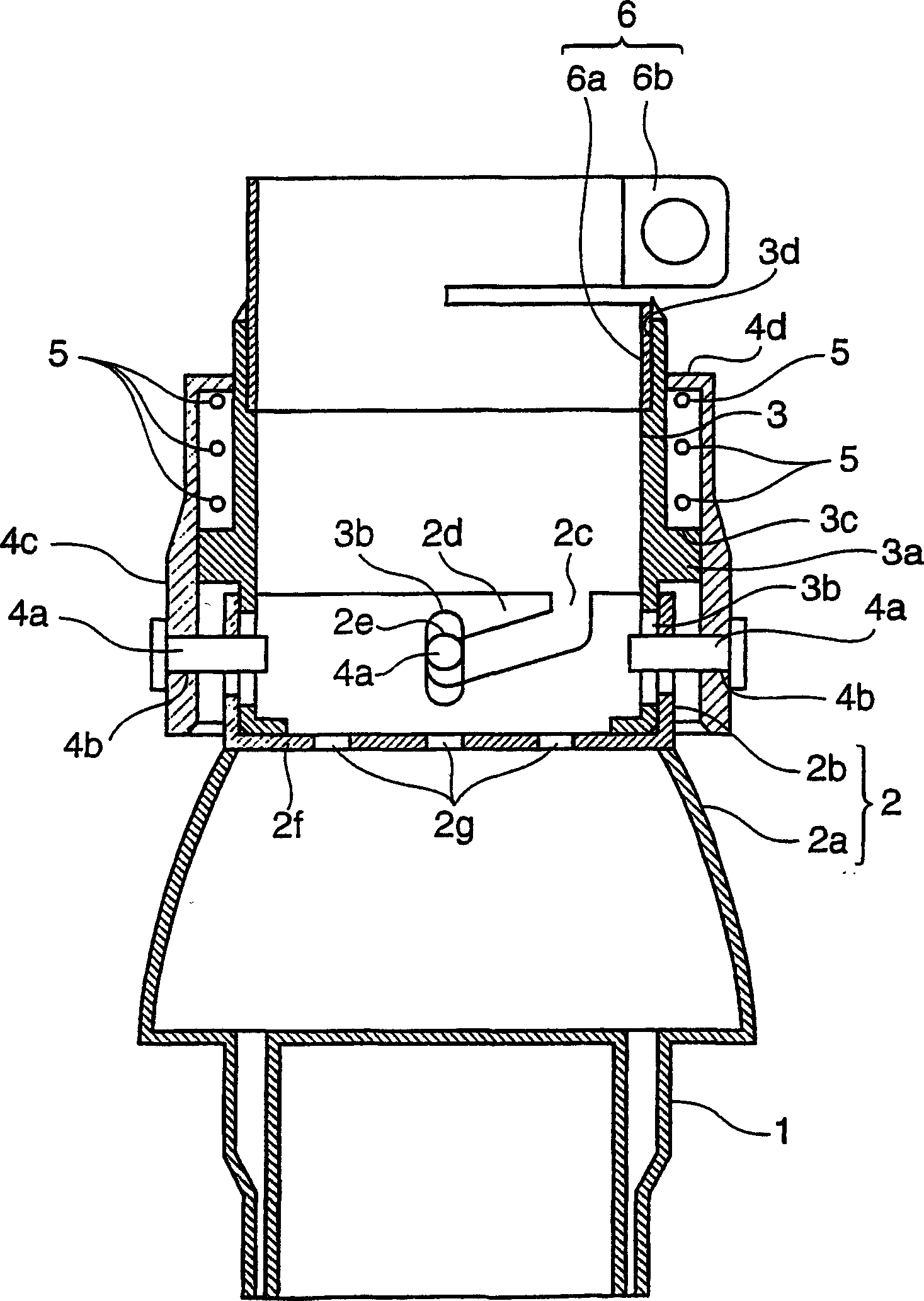

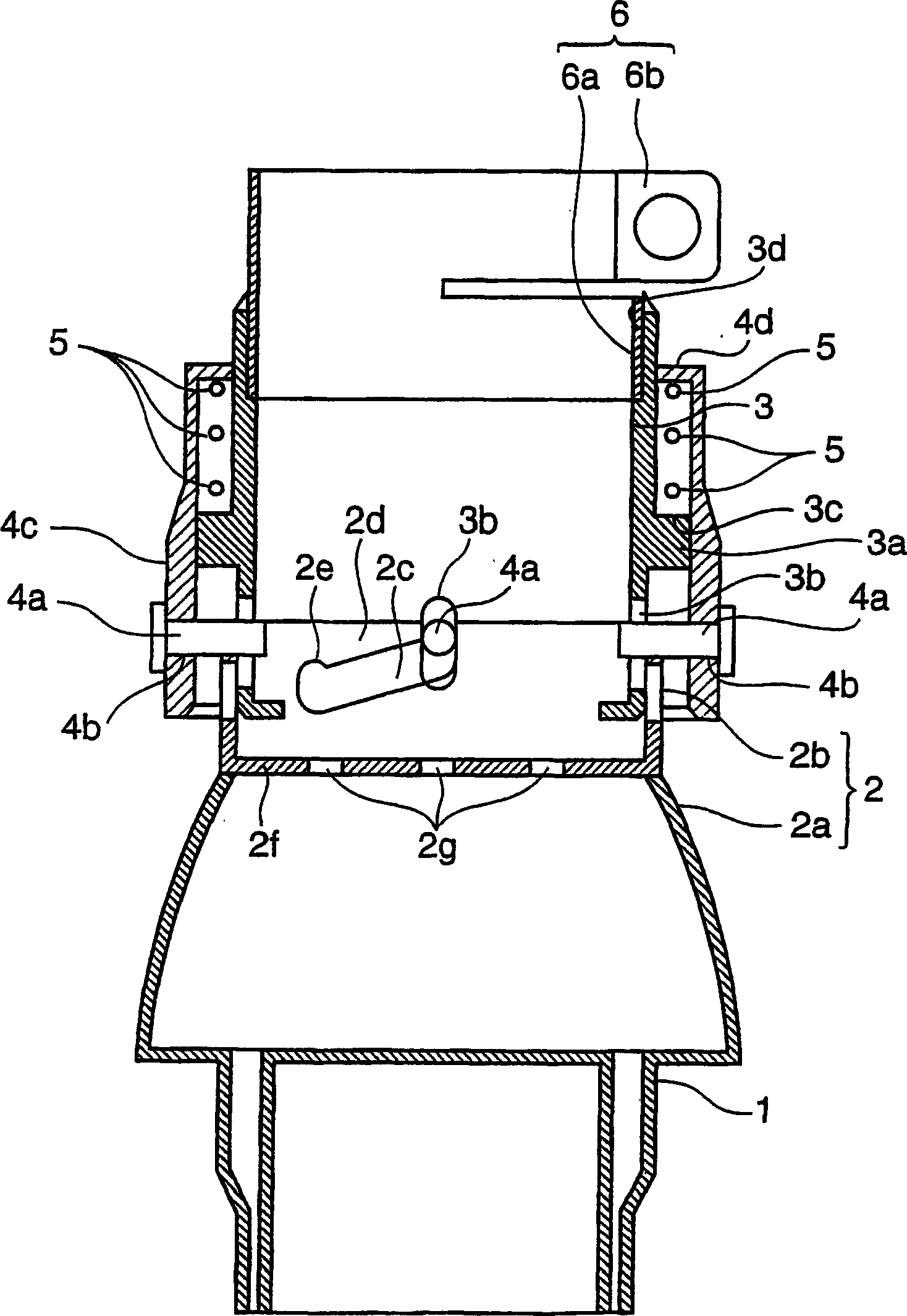

[0015] figure 1 It is an exploded perspective view showing the general structure of the detachable hot gas nozzle according to the embodiment of the present invention, figure 2 It is a cross-sectional view showing a schematic structure of a detachable hot gas nozzle according to an embodiment of the present invention.

[0016] Referring to these figures, the detachable hot gas nozzle 10 related to the embodiment of the present invention includes a nozzle holder 2 supporting the nozzle 1 for spraying hot gas, fittings 3 , a sleeve 4 , and a pressing part 5 .

[0017] In addition, as described later on the role, figure 2 It shows that the above-mentioned nozzle holder 2 is in a fixed state with respect to the fitting 3 .

[0018] The above-mentioned nozzles 1 are used to inject hot gas from the top end to the surroundings of the surface mount components to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com