High frequency heater

A high-frequency heating device and heating chamber technology, which is applied to electric heating devices, microwave heating, and electric heating of fuel, etc., can solve the problems of high material cost, poor cooling efficiency of high-voltage capacitors 2, and reduced assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

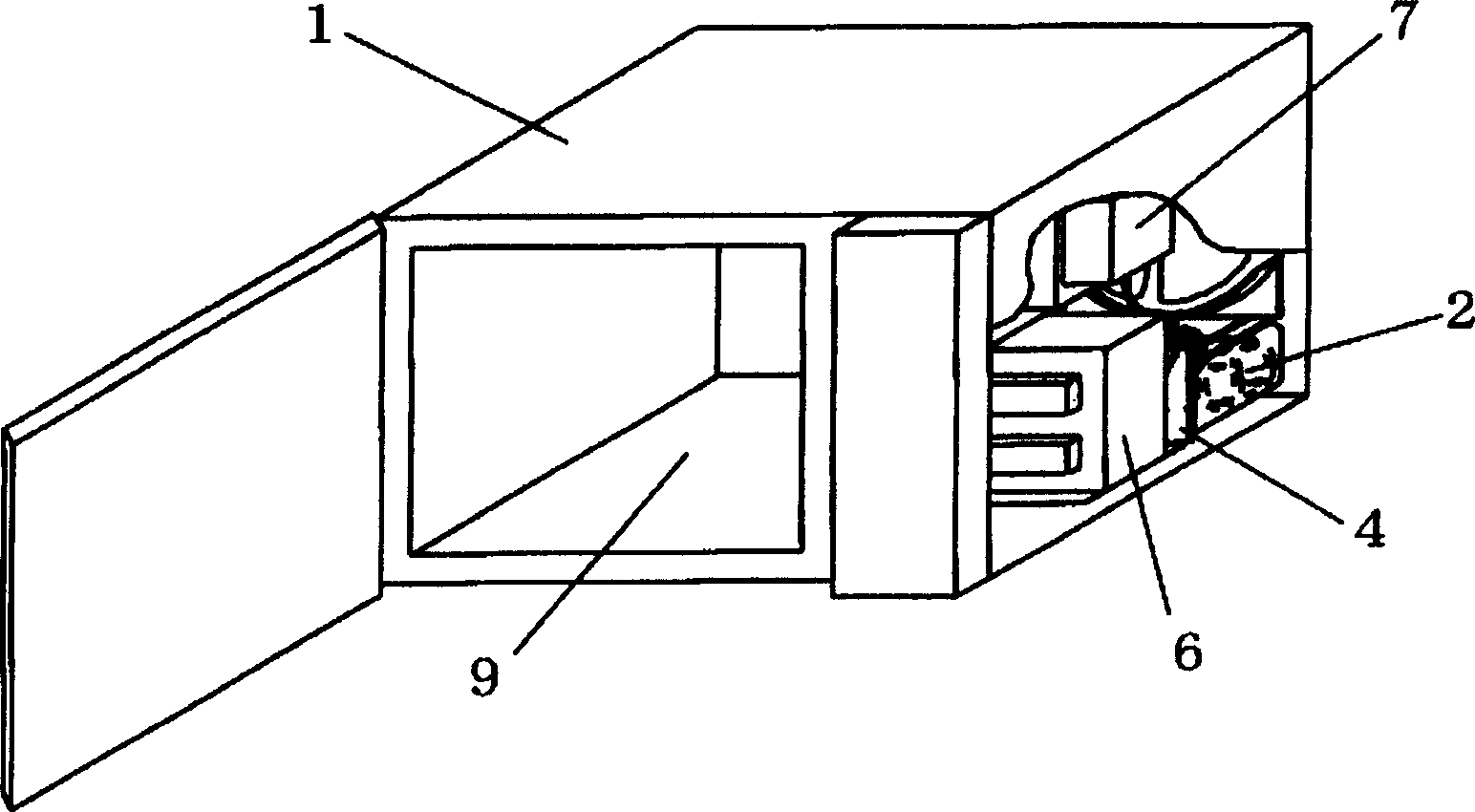

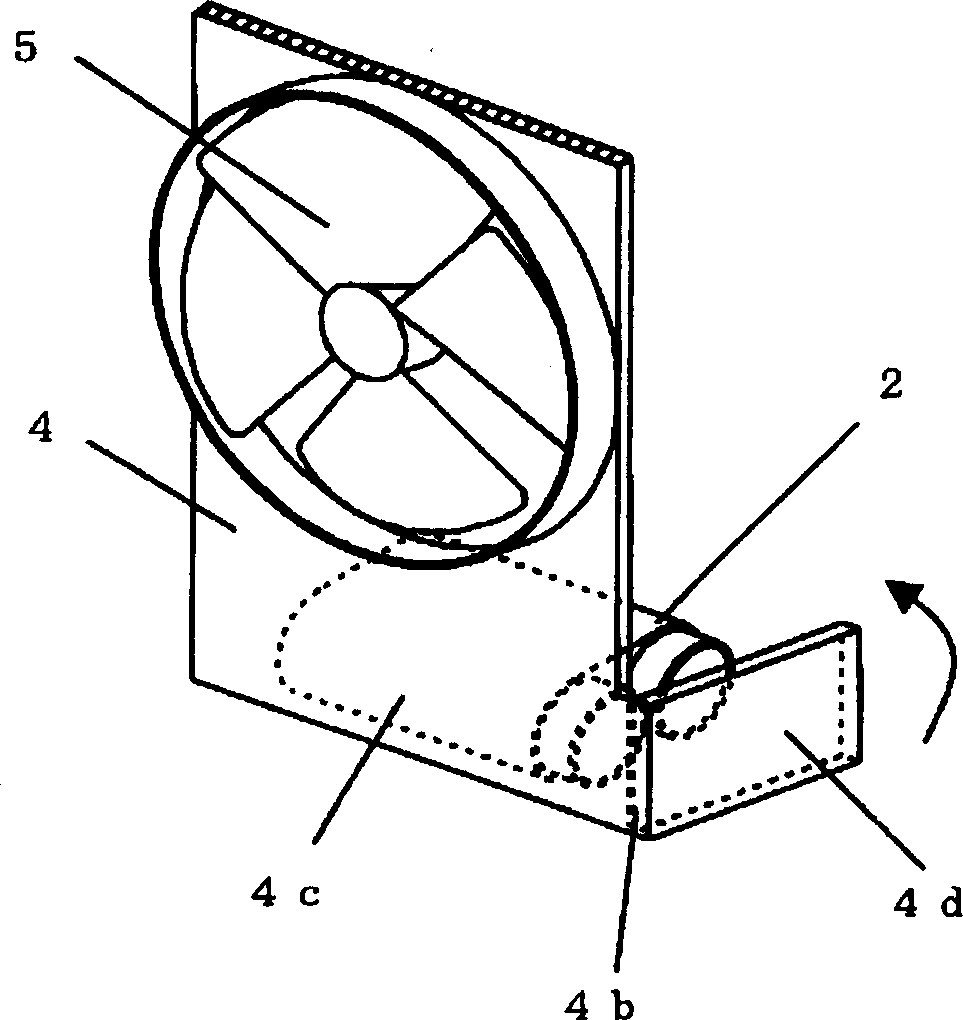

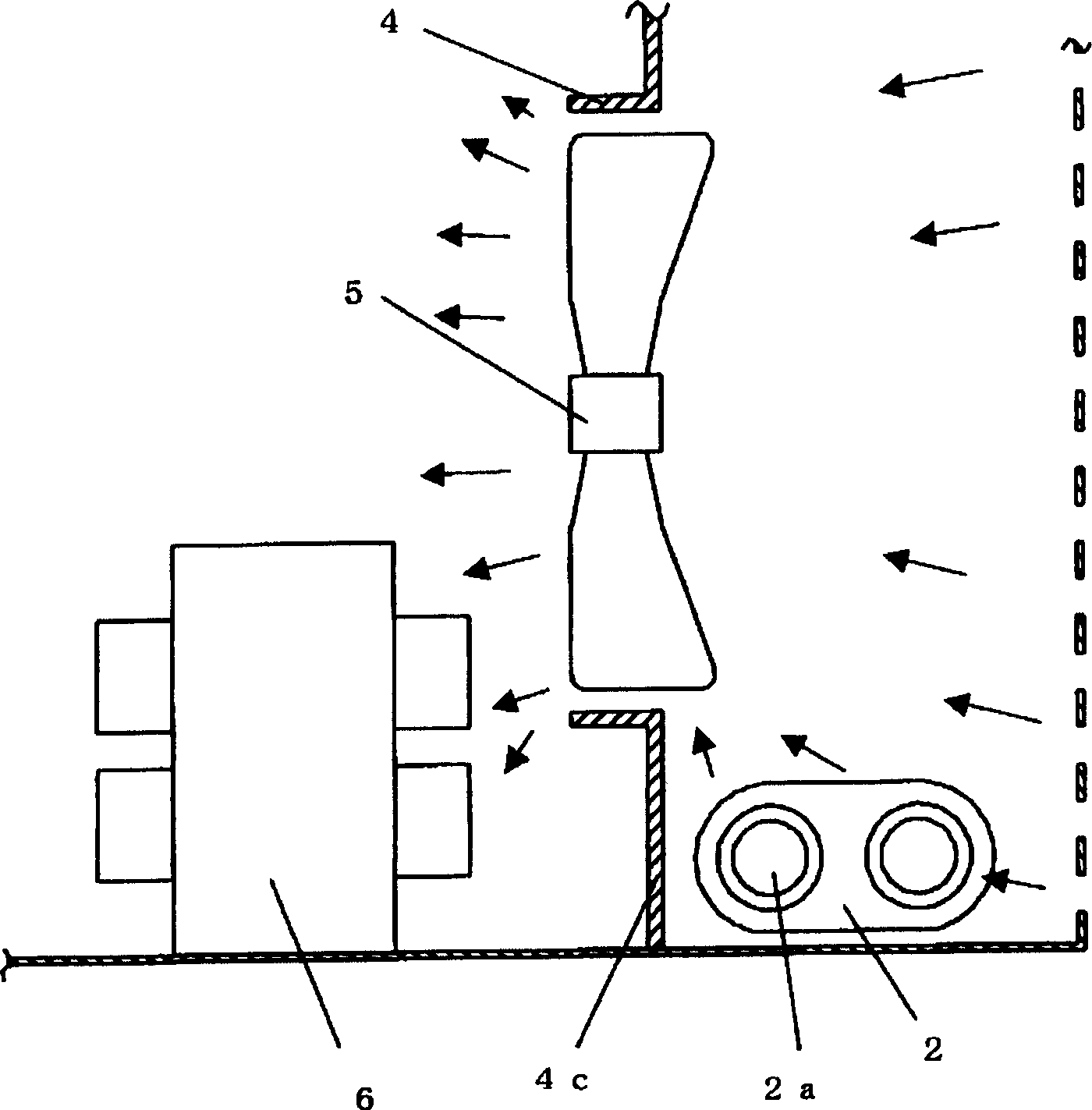

[0036] Figure 1 to Figure 3 shows the high-frequency heating device in the first embodiment of the present invention, figure 1 Its oblique cross-sectional view, figure 2 An enlarged schematic diagram of its main components, image 3 A cross-sectional view of its main components.

[0037] Figure 1 to Figure 3 Among them, 9 is a heating chamber, and the high-voltage capacitor 2 and the high-voltage transformer 6 supply the boosted power to the magnetron 7, and the food placed in the heating chamber 9 is heated. The air guiding member 4 has a partition wall 4c between the high-voltage transformer 6 and the high-voltage capacitor 2. The partition wall 4c is provided with a resin hinge 4b with a partially thinned thickness. When the resin hinge 4b is bent, its front end portion 4d It will be between the terminal part 2a of the high-voltage capacitor 2 and the housing cover 1 which is a non-charging metal.

[0038] As described above, in this embodiment, the resin hinge...

Embodiment 2

[0041] Figure 4 It is an enlarged schematic view of the main components of the air guide member 4 provided with the resin hinge 4b and the high voltage capacitor 2 in the second embodiment of the present invention. The front end part 4d is on the movement track when the casing cover 1 is installed, and the resin hinge 4b will be bent as the operation of installing the casing cover 1 is carried out. This point is different from Example 1. In addition, the same constituent elements as those in Embodiment 1 are assigned the same symbols, and their descriptions are omitted.

[0042] First, when the housing cover 1 is attached, the housing cover 1 contacts the front end portion 4d of the air guide member 4 on its mounting track, bending the resin hinge 4b. As a result, the front end portion 4d bent at the resin hinge 4b will protrude between the terminal portion 2a of the high voltage capacitor 2 and the case cover 1 which is a non-charging metal. The electrical insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com