Liquid detergent automatic adding device for washing machine

A liquid detergent, automatic input technology, applied in the field of washing machines, can solve the problem of difficult to adjust the amount of detergent input, to achieve the effect of improving the use efficiency and washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

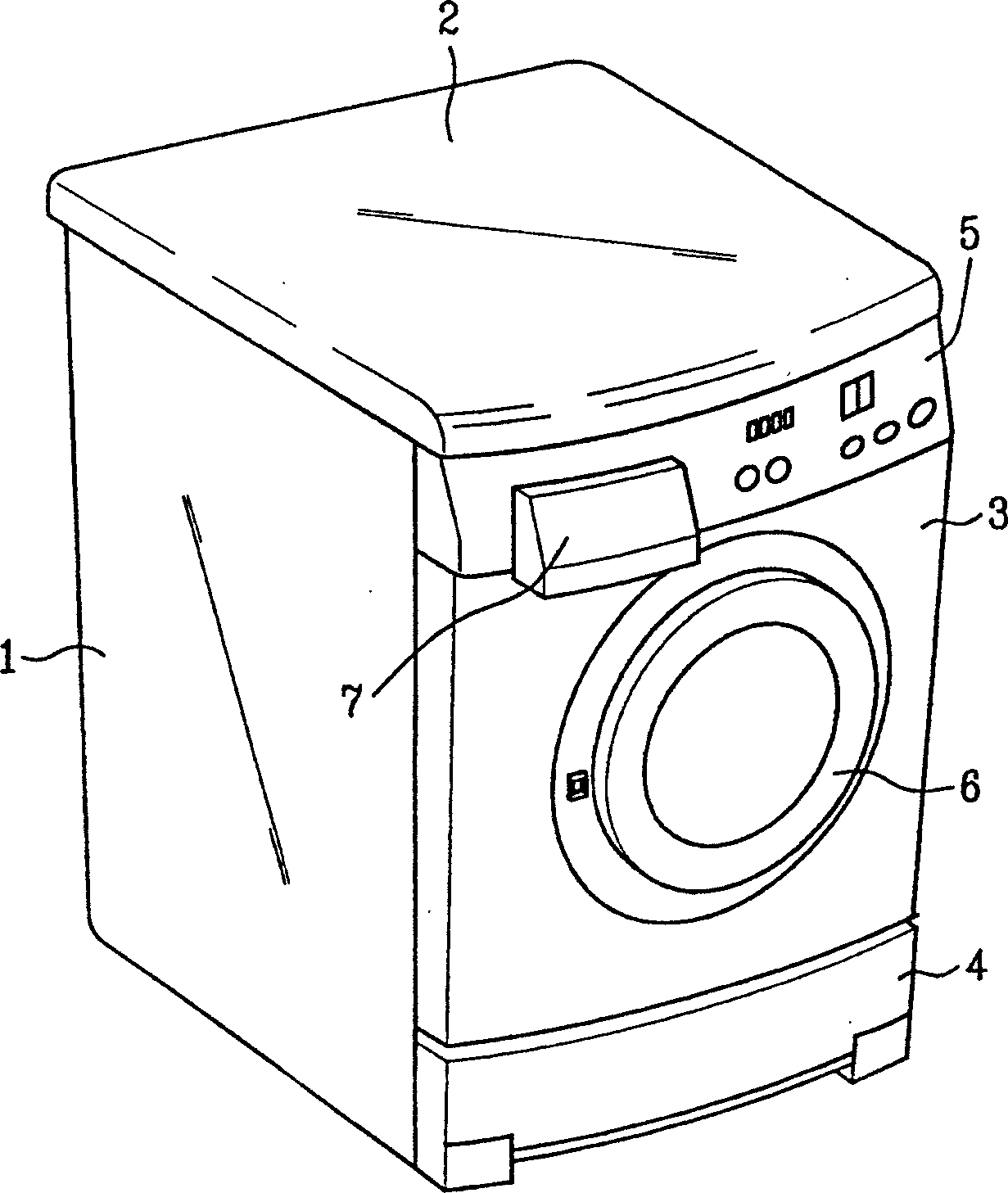

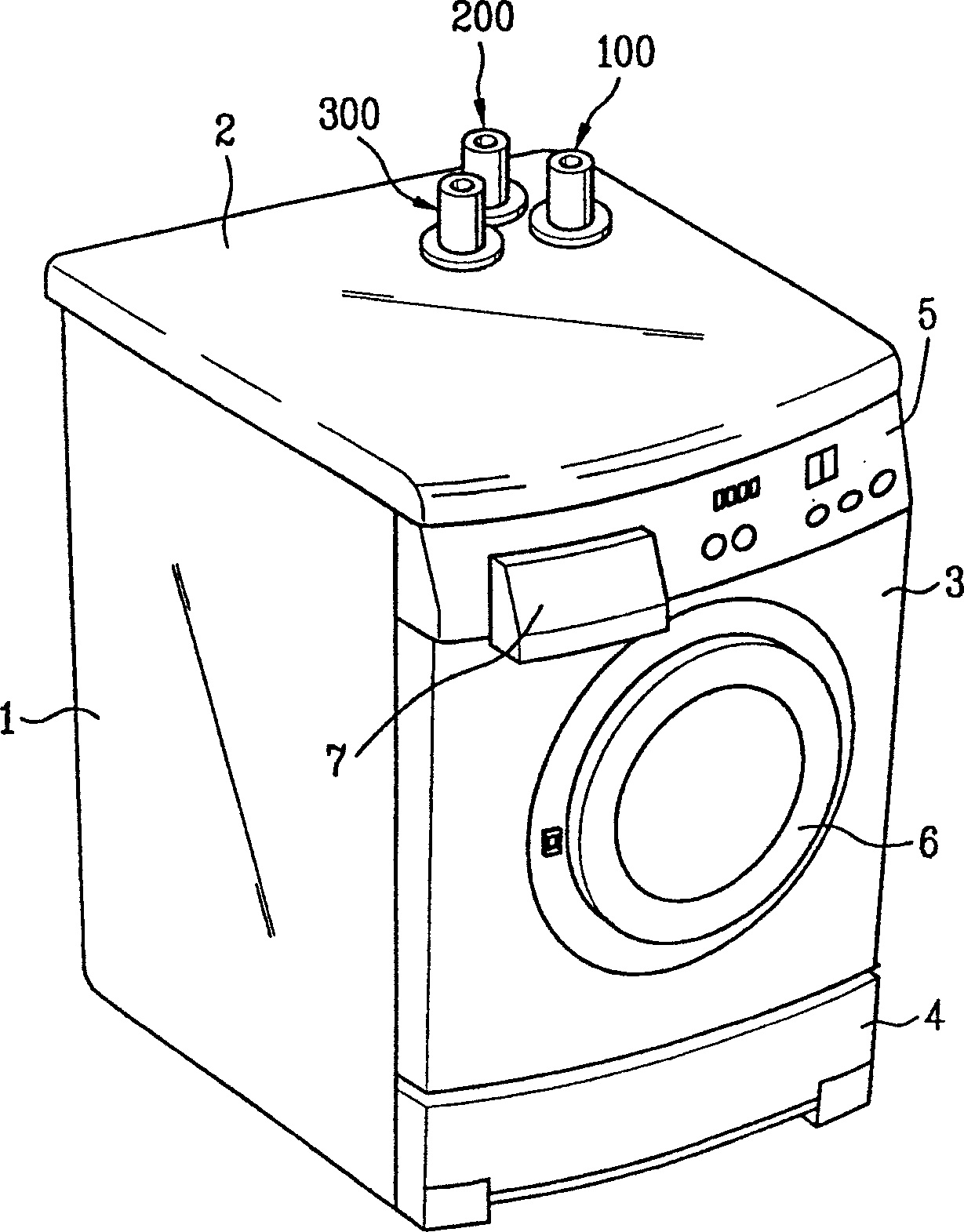

[0025] As shown in the figure, the appearance of the drum washing machine generally includes a casing (1), an upper panel (2) and a front cover (3). In order to protect the washing tank (not shown in the drawing) and various accessories contained in the shell (1), it is composed of left and right sides and the back; the upper panel (2) covers the open upper face of the shell (1); the front A door (6) is arranged on the cover (3).

[0026] At this moment, the top of the front cover (3) is provided with a control panel (5) and a detergent bucket (7). The control panel (5) provides various washing information for the user, and is also provided with a plurality of buttons simultaneously, and the buttons are used for the operation of the user; the detergent bucket (7) is arranged on one side of the control panel (5) for Stores detergent and fabric softener, etc., and automatically injects detergent, etc.

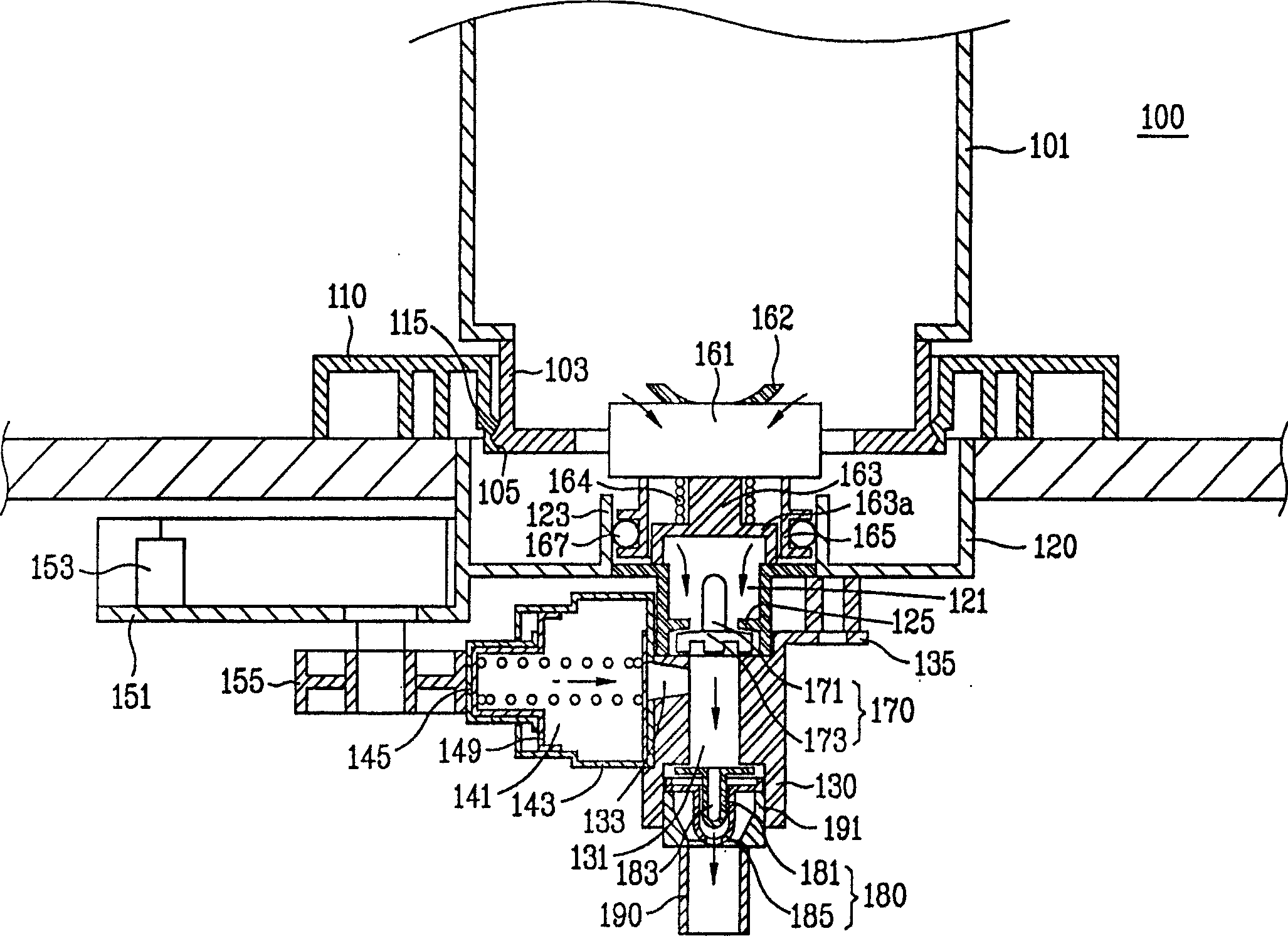

[0027] In addition, the rear side of the upper panel (2) is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com