Deterget feeding device for drum washing machine

A technology of a drum washing machine and a supply device, which is applied to washing devices, other washing machines, applications, etc., to achieve the effect of satisfying diversity and improving washing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The first embodiment and the second embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

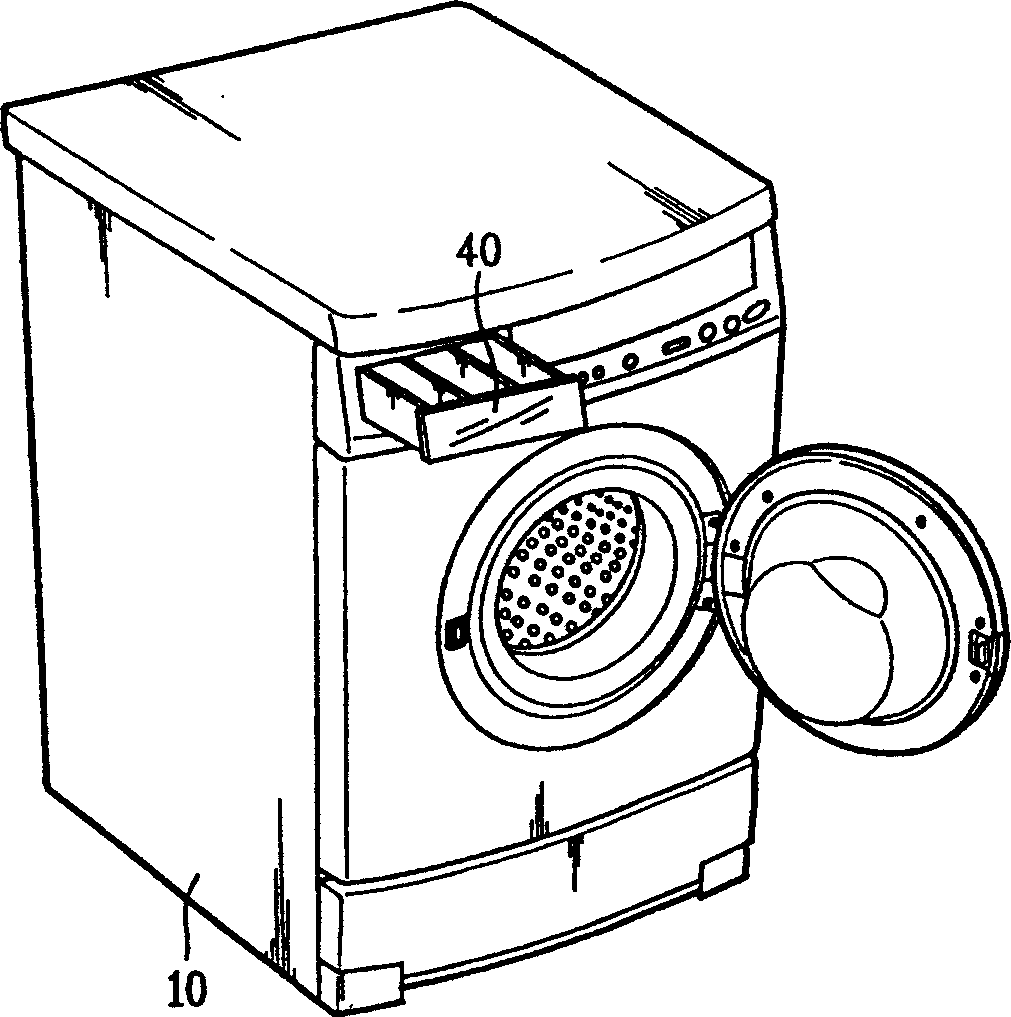

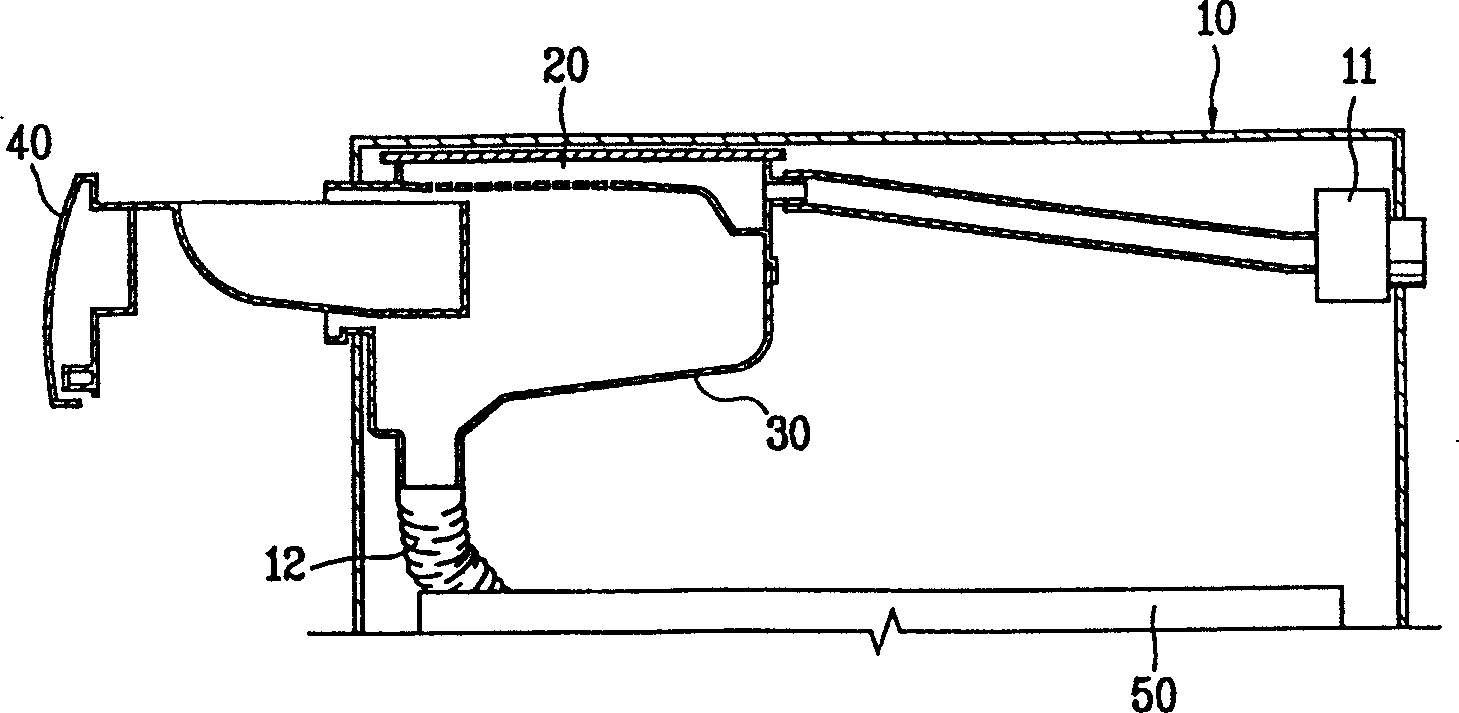

[0038] In the following description, for the main structure of the detergent supply device of the present invention, the same parts as those in the prior art, and figure 1 and figure 2 The components shown have the same reference numerals, and explanations of the same parts are omitted.

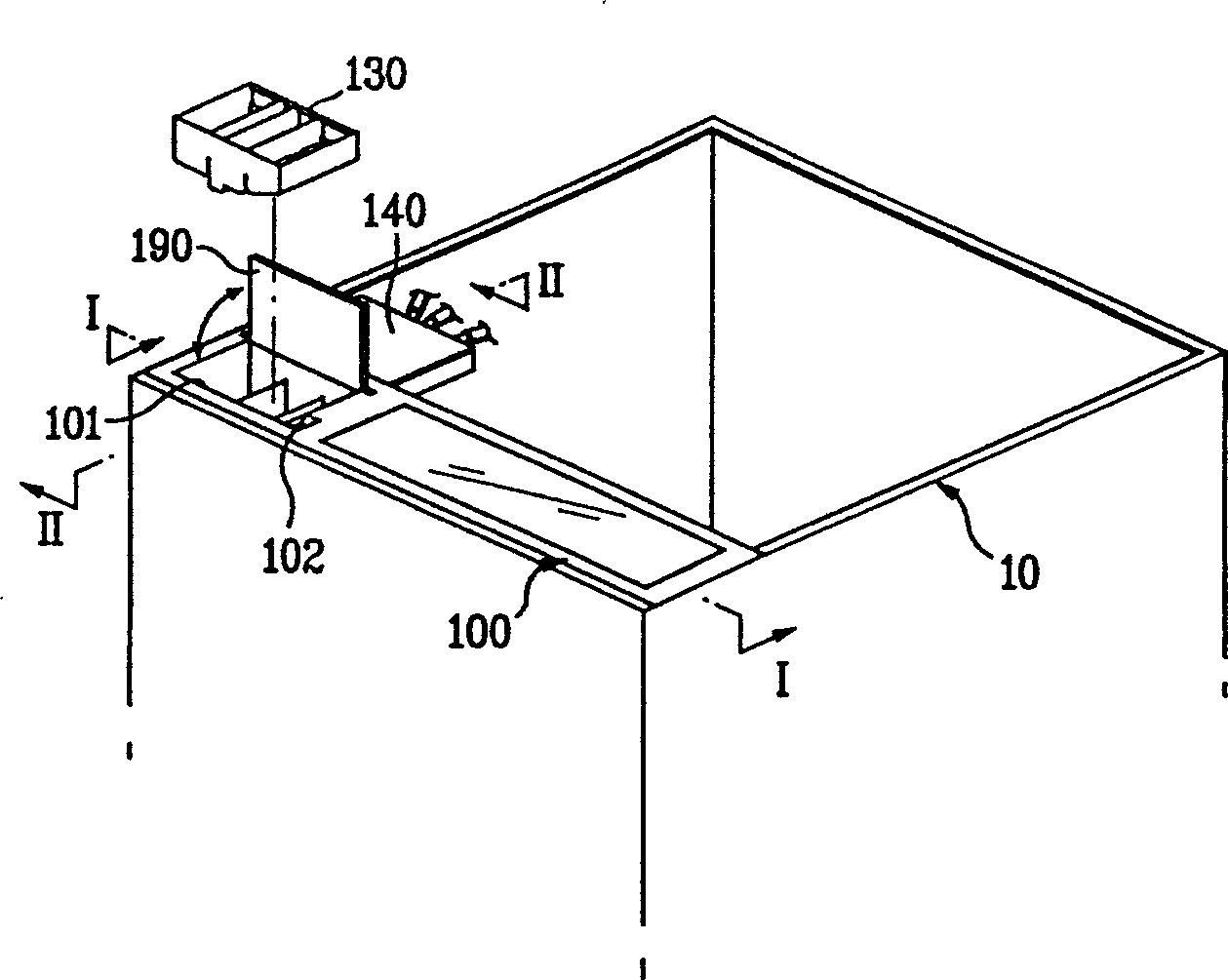

[0039] image 3 A perspective view showing the disassembled state of the composite detergent cylinder of the detergent supply device according to the first embodiment of the present invention, Figure 4 Showing the detached state of the combined detergent cartridge image 3 The I-I line profile, Figure 5 Showing the combined state of the combined detergent cartridge image 3 The II-II line profile, Figure 6 A plan view showing a detached state of the combined detergent tub from the detergent supply device viewed from above.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com