Efficient builder and preparation method thereof

A kind of builder and high-efficiency technology, which is applied in the direction of detergent composition, detergent compounding agent, chemical equipment and methods, etc., can solve the problems of low conversion rate, influence on builder performance, poor dispersion of polymer products, etc., and achieve Reduce the harm of environmental pollution, improve the anti-redeposition ability, and increase the effect of dispersion retention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

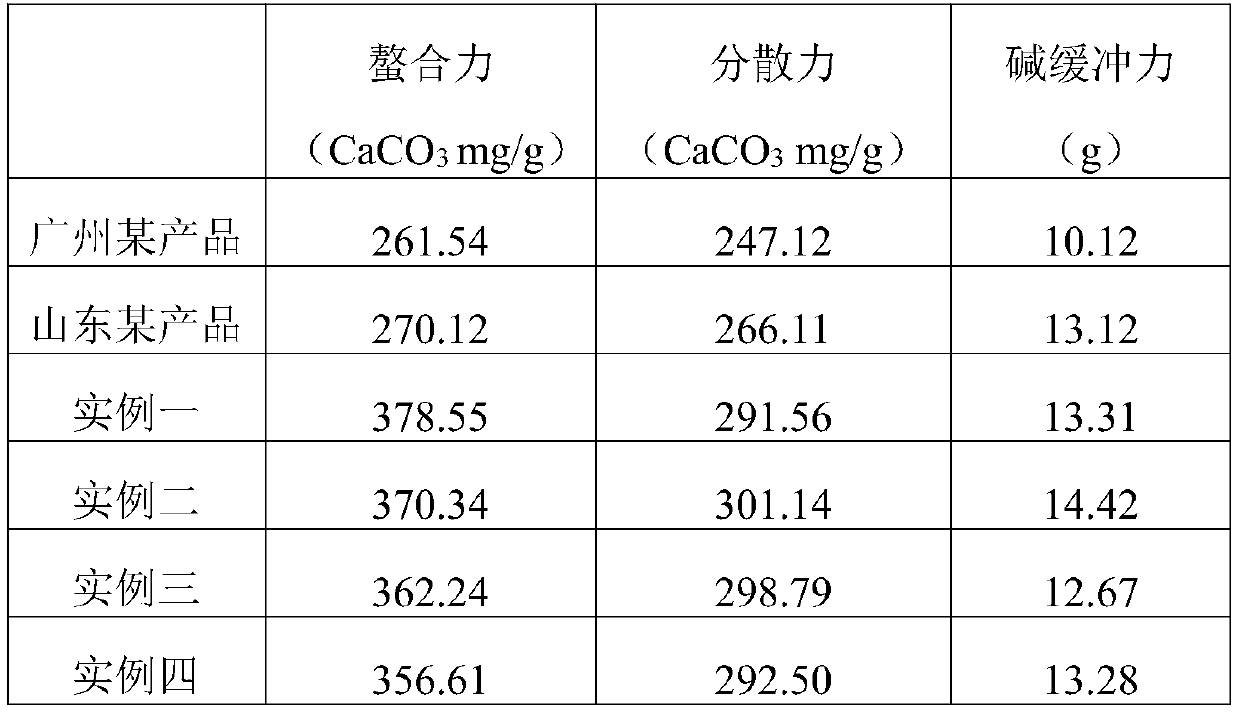

Examples

Embodiment 1

[0026] A kind of preparation method of efficient builder:

[0027] Partially react 1 mol of acrylic acid and 0.6 mol of neopentyl glycol phosphorus oxychloride to obtain unsaturated monomer I containing phosphate groups, and then add 0.6 mol of 2-amphetamine to the above reaction system for reaction to obtain amide group-containing The unsaturated monomer II, and 3 mol of acrylic acid, under the action of 0.01 mol of sodium persulfate and 0.03 mol of sodium bisulfite, were kept at 70°C for free radical reaction for 3 hours to obtain a polymer with a mass concentration of 30 % to obtain potassium hydroxide solution to adjust the pH to be neutral, add water to obtain a builder solution with a mass concentration of 40%.

[0028] The high-efficiency builder prepared according to the above-mentioned preparation method.

Embodiment 2

[0030] A kind of preparation method of efficient builder:

[0031] Partially react 1.2 mol of butyl acrylate and 0.6 mol of neopentyl glycol phosphorous oxychloride to obtain unsaturated monomer I containing phosphate groups, and then add 0.6 mol of 2-amphetamine to the above reaction system for reaction to obtain The unsaturated monomer II containing amide group, and 3 mol of acrylic acid, under the action of 0.01 mol of ammonium persulfate and 0.03 mol of sodium pyrophosphite, kept at 75°C for free radical reaction for 3.5 hours to obtain a polymer, with a mass concentration of The pH of the 40% sodium hydroxide solution is adjusted to be neutral, and water is added to obtain a builder solution with a mass concentration of 40%.

[0032] The high-efficiency builder prepared according to the above-mentioned preparation method.

Embodiment 3

[0034] A kind of preparation method of efficient builder:

[0035] Partially react 1 mol of acrylic acid and 0.6 mol of neopentyl glycol phosphorus oxychloride to obtain unsaturated monomer I containing phosphate groups, and then add 0.6 mol of 2-amphetamine to the above reaction system for reaction to obtain amide group-containing The unsaturated monomer II, and 3 mol of acrylic acid, under the action of 0.01 mol of potassium persulfate and 0.03 mol of sodium bisulfite, kept at 80 ℃ for free radical reaction for 4 hours to obtain a polymer, with a mass concentration of 30% Liquid ammonia is used to adjust the pH to be neutral, and water is added to obtain a builder solution with a mass concentration of 40%.

[0036] The high-efficiency builder prepared according to the above-mentioned preparation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com