Acrylic resin emulsion for hair dressing, hair dressing containing same, and hair styling method

A technology of acrylic resin and hair conditioner, which is applied in the field of acrylic resin emulsion, which can solve the problem that hair can no longer be styled, and achieve the effect of excellent redispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

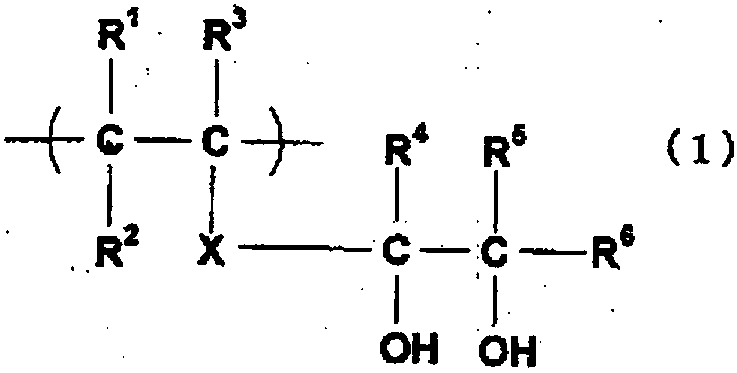

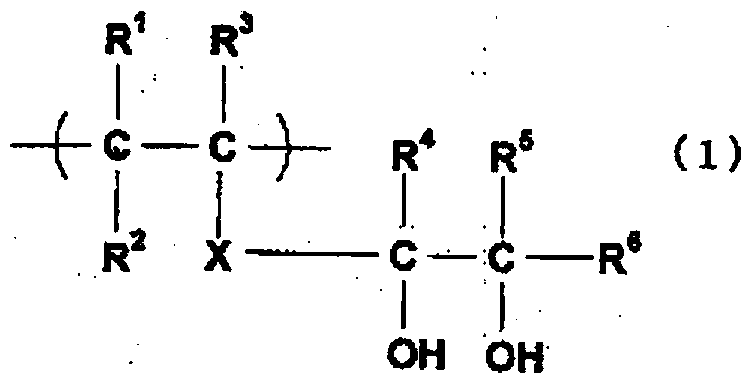

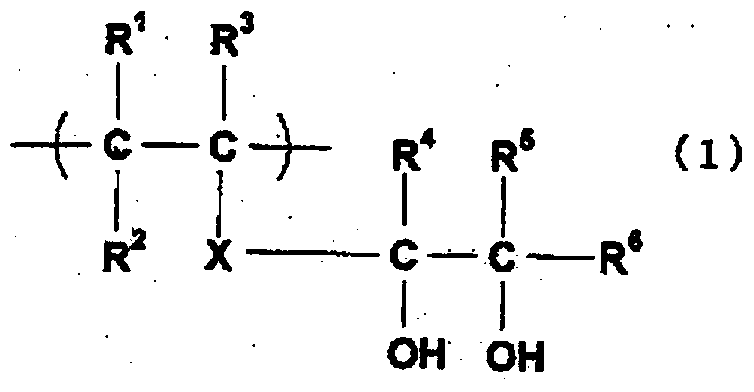

Image

Examples

Embodiment 1

[0143]

[0144] In a reaction tank made of SUS equipped with cooling pipes and stirring blades, a PVA-based resin containing a 1,2-diol structural unit in the side chain (average degree of saponification 99 mol%, average degree of polymerization 300, side chain 1,2- The content of diol structural unit (8 mol% / Nippon Synthetic Chemical Industry Co., Ltd.) 10 parts, 0.2 parts of sodium bisulfite and 0.4 parts of sodium carbonate trihydrate are completely dissolved in deionized water (92 parts), and the temperature is raised to 75°C.

[0145] Prepare in advance a substance emulsified with 77 parts of deionized water, unmodified PVA-based resin (manufactured by Nippon Synthetic Chemical Industry Co., Ltd.; trade name "GOHSENOL GL05"), and 100 parts of 2-ethylhexyl acrylate ( i), and 2.7 parts of 10% APS (ammonium persulfate) aqueous solution (ii), first add 10% of (i) and 30% of (ii) to the reaction tank, and make it react for 45 minutes.

[0146] Next, the remaining 90% of (i)...

Embodiment 2

[0149]

[0150] In embodiment 1, 100 parts of 2-ethylhexyl acrylate are changed to 90 parts of 2-ethylhexyl acrylate and 10 parts of methyl methacrylate, and then as unmodified PVA resin, "GOHSENOL GL05" (trade name , Nippon Synthetic Chemical Industry Co., Ltd.) was changed to the product name "GOHSENOL EG05" produced by Nippon Synthetic Chemical Industry Co., Ltd., except that it was carried out in the same manner as Example 1 to obtain an acrylic resin emulsion (2) (non-volatile component 43 %; viscosity 160 mPa·s (B-type viscometer 12 rpm, 23°C); glass transition temperature (Tg) of acrylic resin = -60°C). The acrylic resin emulsion (2) is dispersed and stabilized.

Embodiment 3

[0151]

[0152]In Example 2, 0.3 parts of ethylene glycol dimethacrylate (manufactured by MitsubishRayon Co., Ltd.; trade name "ACRYESTER ED") was further added as an acrylic acid monomer, and the procedure was carried out in the same manner as in Example 2. , to obtain an acrylic resin emulsion (3) (44% non-volatile content; viscosity 210mPa·s (B-type viscometer 12rpm, 23°C); glass transition temperature (Tg) of acrylic resin=-60°C). The acrylic resin emulsion (3) is dispersed and stabilized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com