Kerosene stove

A technology of kerosene and combustion chambers, which is applied to household stoves/stoves, combustion methods, heating fuels, etc., and can solve problems such as blocking flames, incomplete combustion, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

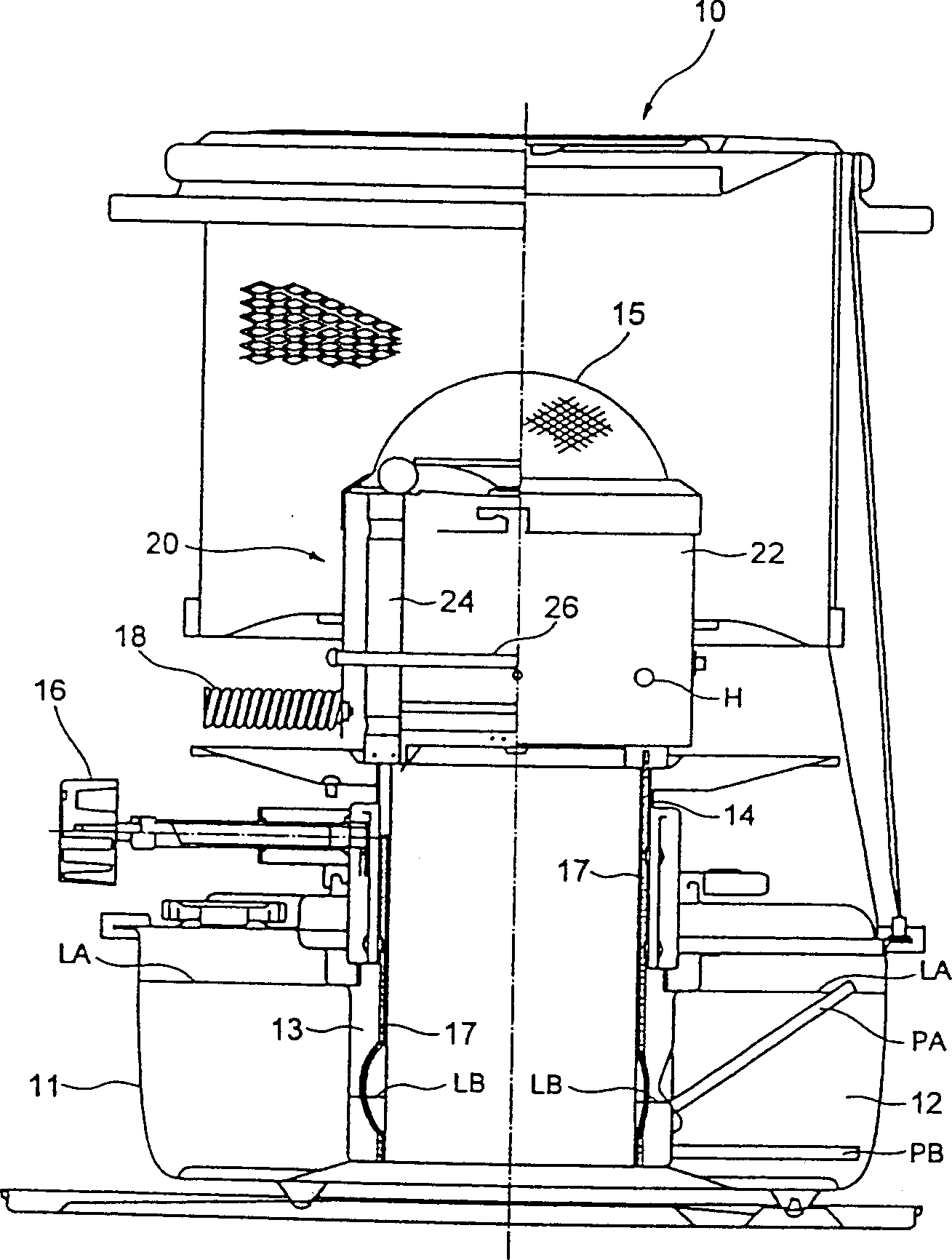

[0024] Embodiments of the present invention use Figure 2 ~ Figure 6 To illustrate.

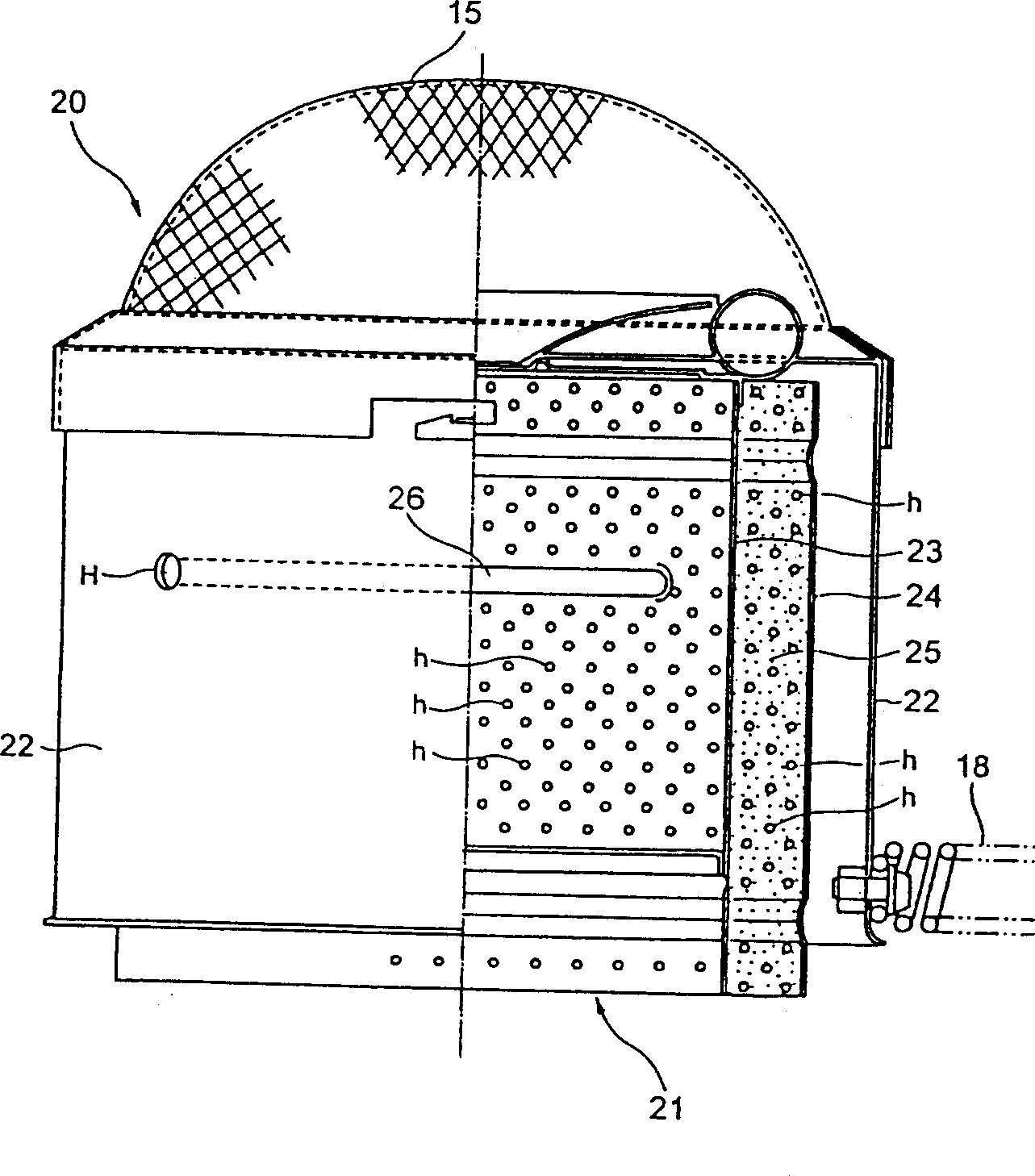

[0025] figure 2 means as mentioned above figure 1 A diagram of the combustion section 20 of the kerosene stove 10 is shown.

[0026] In addition, this combustion unit 20 is equipped with a flame stabilizing wire mesh on the upper part of the outer cylinder 22, and also has a knob 18 for opening and closing the combustion unit. The combustion chamber 25 is a circumferential space formed by the inner flame tube 23 and the outer flame tube 24; at the lower end of the combustion chamber 25, as figure 1 As shown, the top part of the combustion core body 17 is inserted or pulled out by the up and down adjusting knob 16.

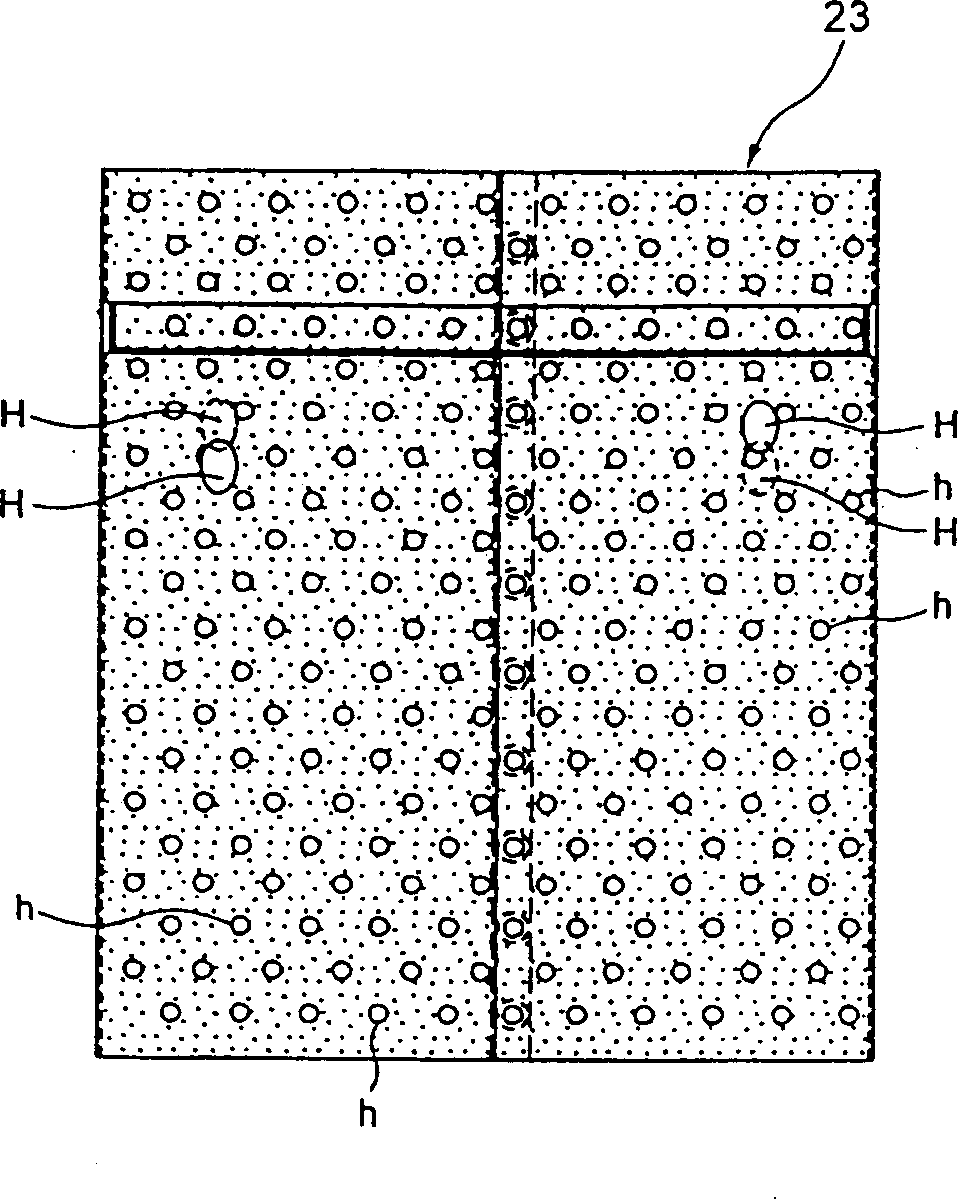

[0027] figure 2 The right half of the above-mentioned combustion part 20 is shown in section. In this figure, the inner flame tube 23 and the outer flame tube 24 each have a plurality of ventilation holes h~h, and air is supplied from the inner and outer sides of the combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com