A control device for a gas infrared burner

A control device, infrared technology, applied in the direction of gas fuel burner, burner, combustion method, etc., can solve the problems of poor ignition performance, difficulty in ignition, low gas concentration, etc., and achieve good control performance and ignition performance, simple structure Reliable, good combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

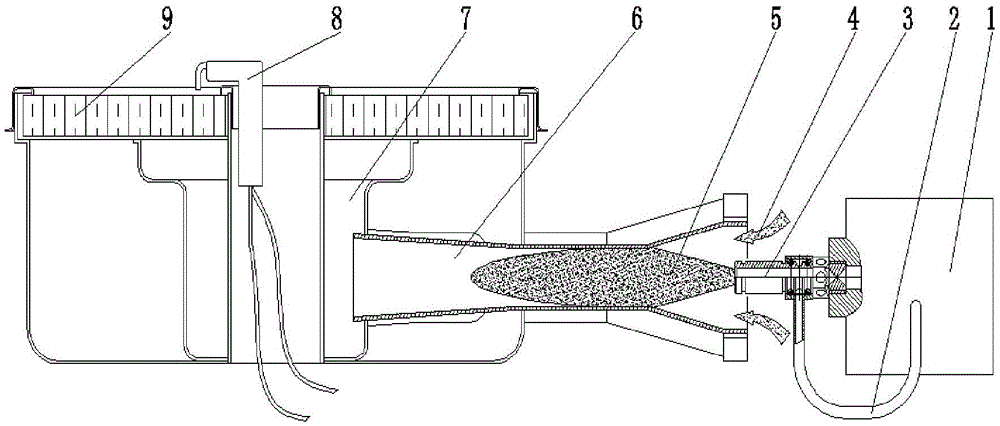

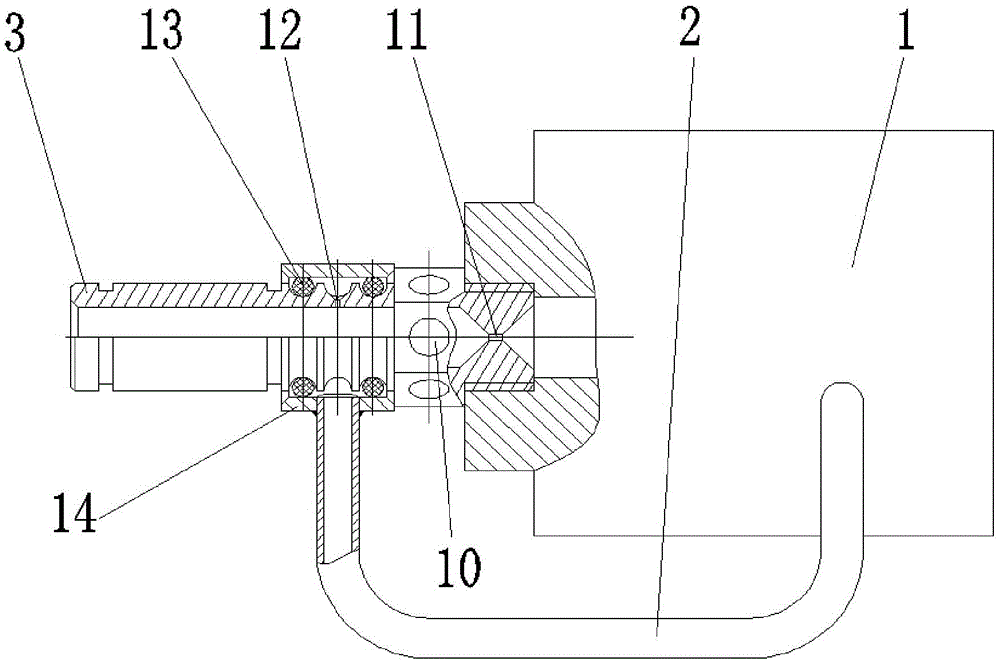

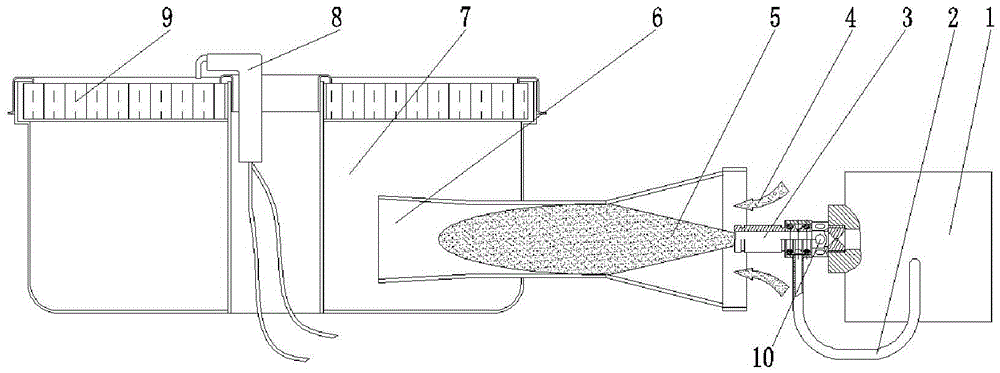

[0035] see figure 1 and figure 2 , the first embodiment of the control device for the gas infrared main burner of the present invention includes a gas channel composed of a gas control valve 1, a nozzle 3, an ejector tube 6 and a furnace chamber 7 through which the gas passes sequentially, and the gas passes through the gas channel. The axial gas flow is formed to flow to the porous combustion radiant plate 9 and is ignited and burned by the ignition needle 8. The gas channel is provided with a radial auxiliary nozzle, which injects a radial gas flow into the gas channel at the beginning of ignition. Immediately stop.

[0036] Specifically, for the embodiment in which the auxiliary nozzle is arranged on the nozzle when the control device is suitable for the double-ring main burner: the tubular nozzle 3 is covered with a sleeve 14, and the two ends of the sleeve or the nozzles corresponding to the two ends of the sleeve are provided with The concave ring is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com