Method for preparing carbon nanotubes by low-pressure combustion of coking crude benzol

A technology for carbon nanotubes and coking crude benzene, which is applied in the fields of carbon nanotubes, chemical instruments and methods, nanocarbons, etc., can solve the problems of preparing carbon nanotubes that have not yet been discovered, and achieves low cost, stable flame state, and extended growth time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

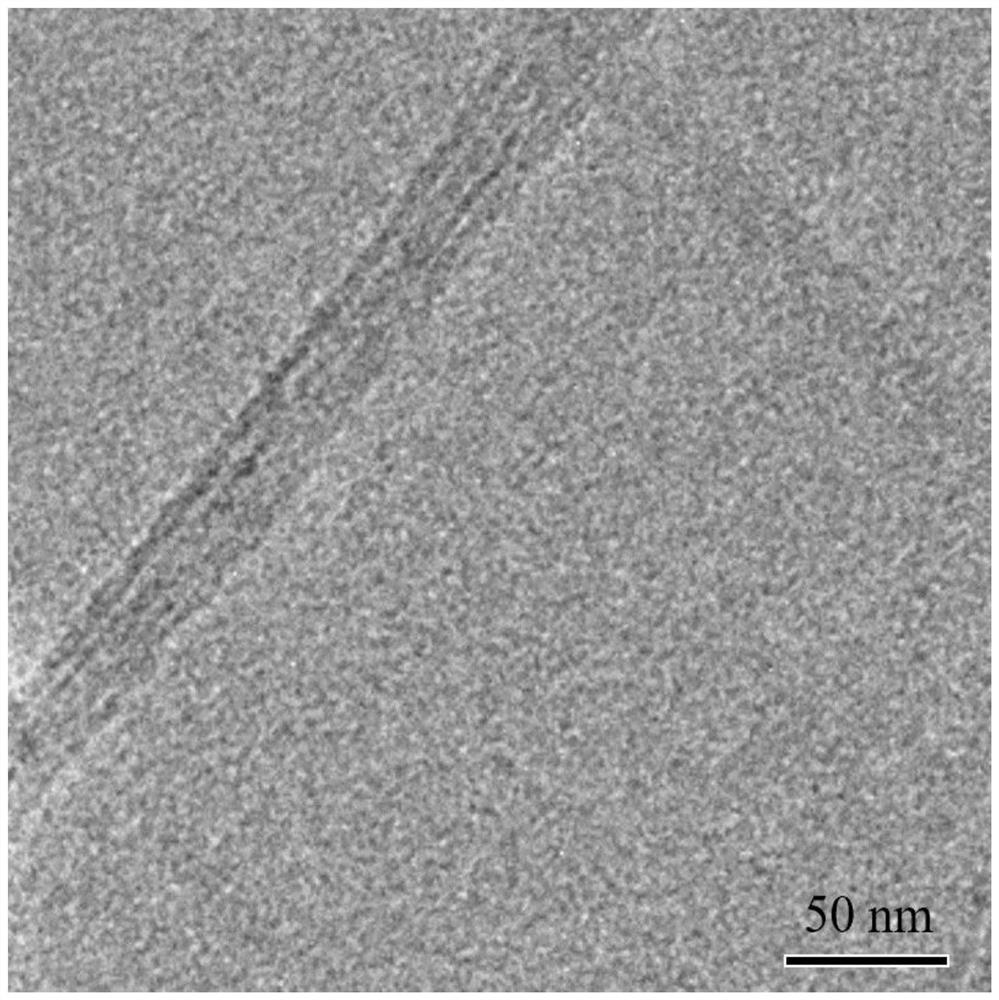

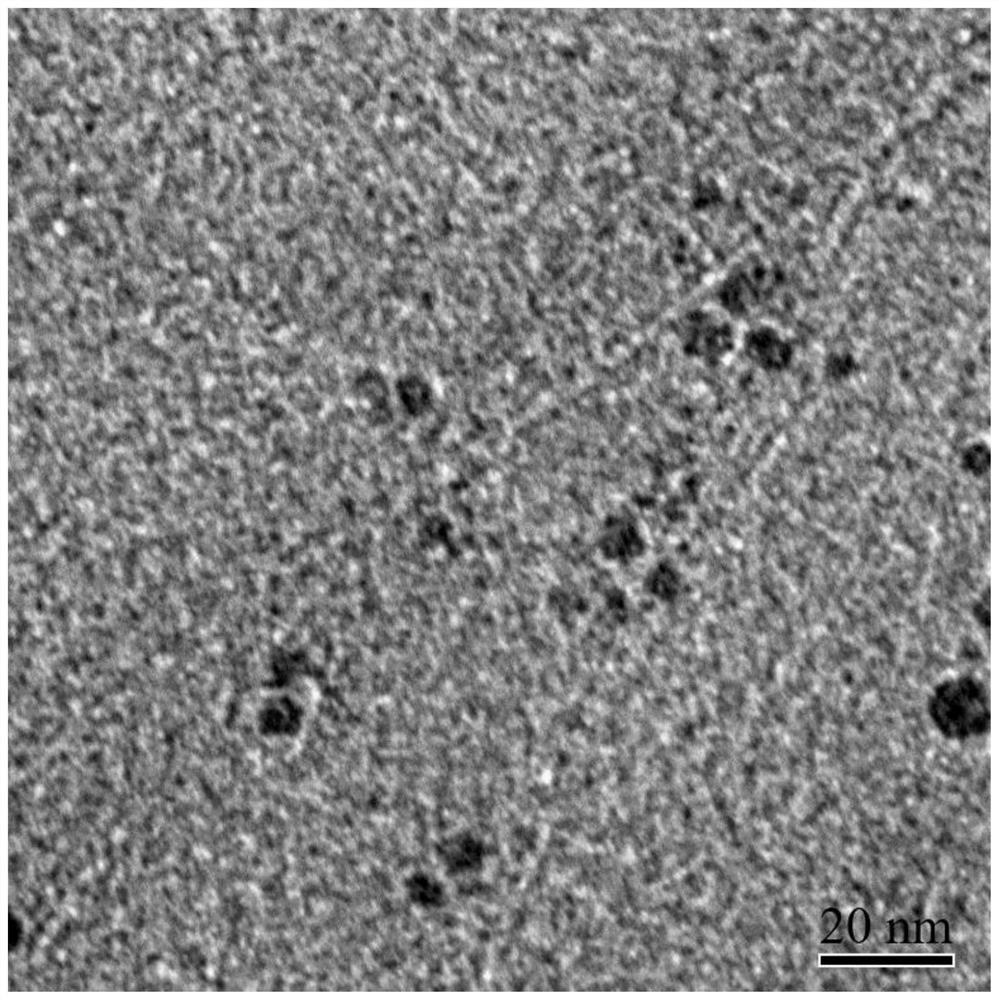

Image

Examples

Embodiment 1

[0031] Using coking crude benzene as raw material to prepare carbon nanotubes, the steps are as follows:

[0032] 1) Dissolve 0.75 mg of nickelocene in 50 mL of coking crude benzene, and stir at room temperature for 30 min to form an active component precursor solution;

[0033] 2) Under the low pressure space of 75KPa, the active component precursor solution obtained in step 1) is loaded into a syringe to control the supply rate of the active component precursor solution by a syringe pump, and it is atomized with an atomizing device and mixed with the solution. Oxygen, which is controlled by a gas mass flow meter, is mixed and ignited to establish a flame;

[0034] 3) Adjust the gas mass flowmeter to make the oxygen rate 2L / min, and adjust the injection rate of the syringe pump to make the supply rate of the active component precursor solution 4.5×10 -3 L / min, burn to obtain the crude carbon nanotube product; use the pressure difference formed between the low pressure space ...

Embodiment 2

[0038] Using coking crude benzene as raw material to prepare carbon nanotubes, the steps are as follows:

[0039] 1) Dissolve 0.70 mg of nickelocene in 50 mL of coking crude benzene, and stir at room temperature for 30 min to form an active component precursor solution;

[0040] 2) Under the low pressure space of 75KPa, the active component precursor solution obtained in step 1) is loaded into a syringe to control the supply rate of the active component precursor solution by a syringe pump, and it is atomized with an atomizing device and mixed with the solution. Oxygen, which is controlled by a gas mass flow meter, is mixed and ignited to establish a flame;

[0041] 3) Adjust the gas mass flowmeter to make the oxygen rate 3L / min, and adjust the injection rate of the syringe pump to make the supply rate of the active component precursor solution 5.0×10 -3L / min, burn to obtain the crude carbon nanotube product; Utilize the pressure difference formed between the low pressure spa...

Embodiment 3

[0045] Using coking crude benzene as raw material to prepare carbon nanotubes, the steps are as follows:

[0046] 1) Dissolve 0.75 mg of ferrocene in 60 mL of coking crude benzene, and stir at room temperature for 30 min to form an active component precursor solution;

[0047] 2) Under the low pressure space of 70KPa, the active component precursor solution obtained in step 1) is loaded into the syringe and the supply rate of the active component precursor solution is controlled by a syringe pump, and it is atomized with an atomizing device and mixed with the solution. Oxygen, which is controlled by a gas mass flow meter, is mixed and ignited to establish a flame;

[0048] 3) Adjust the gas mass flowmeter to make the oxygen rate 2.5L / min, and adjust the injection rate of the syringe pump to make the supply rate of the active component precursor solution 3.0×10 -3 L / min, burn to obtain the crude carbon nanotube product; Utilize the pressure difference formed between the low pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com