Tiltable bush spring sheet assembly for gas turbine

A technology of gas turbines and spring sheets, which is applied to engine components, mechanical equipment, machines/engines, etc., to achieve the effects of reducing unevenness, simple structure, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

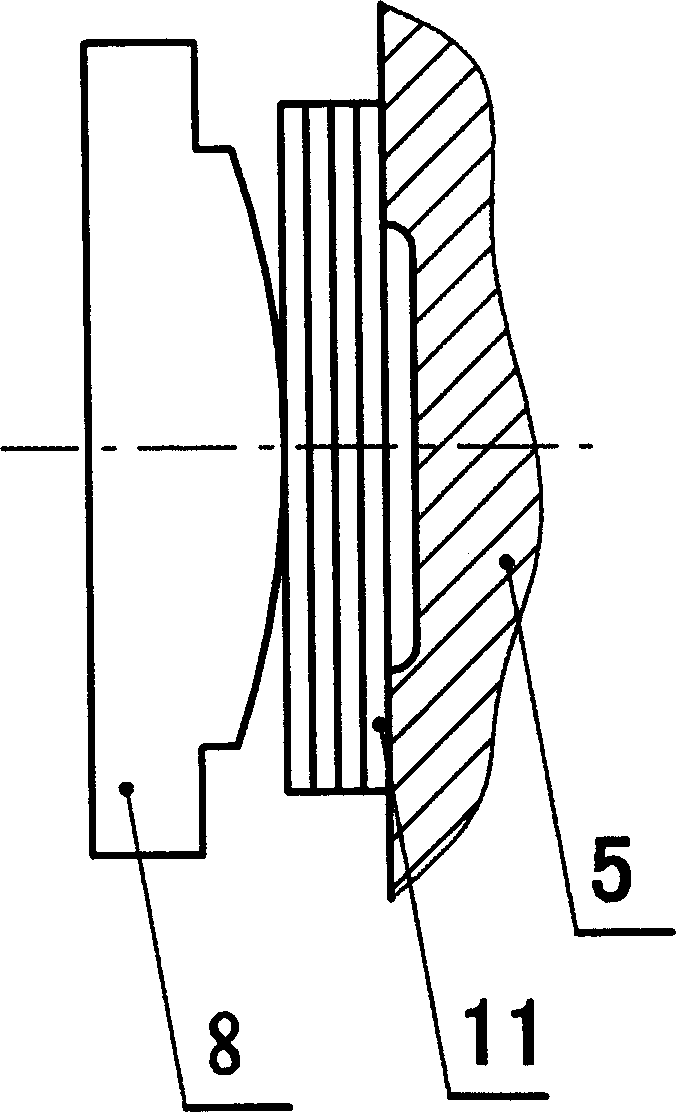

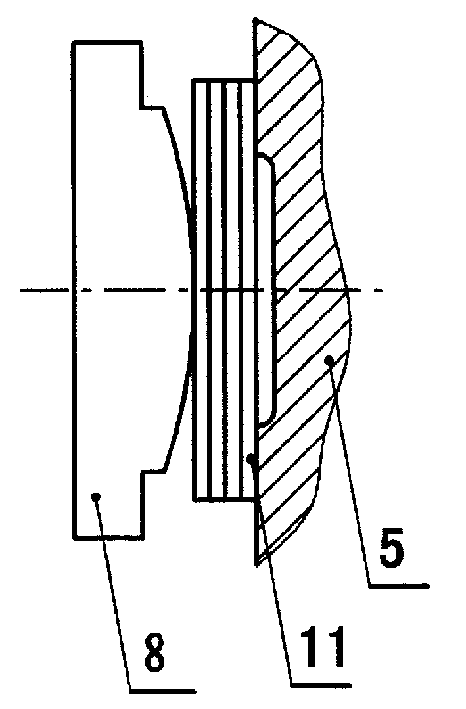

[0017] Depend on figure 1 It can be seen that the gas turbine (1) is composed of a compressor, a combustion chamber and a turbine, and the power generated by the turbine is used to drive a generator or other working machines except for driving the compressor, wherein the compressor casing, the combustion chamber and the turbine The casing (2) is stationary on the gas turbine, while the compressor and turbine rotating parts consist of several disks, shafts and blades, arranged on a common rotor part (3), all parts of the rotor are Rotate at high speed around the rotor axis of rotation.

[0018] There are shafts (4) at the front and rear ends of the rotor of the gas turbine, and the rotor is supported on the stationary casing of the gas turbine through radial sliding bearings (6) and bearing casings (5) on the front and rear shafts to transmit the rotor mass force and rotational unbalance Force to the stationary receiver.

[0019] A thrust disc (9) is fixed on the front shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com