Pipe body making method, pipe body and image forming device using the same

A manufacturing method and a technology for a pipe body, applied to the manufacture of the pipe body, can solve the problems of unconfirmed occurrences and increased cost, and achieve the effects of suppressing cost increase, improving strength, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

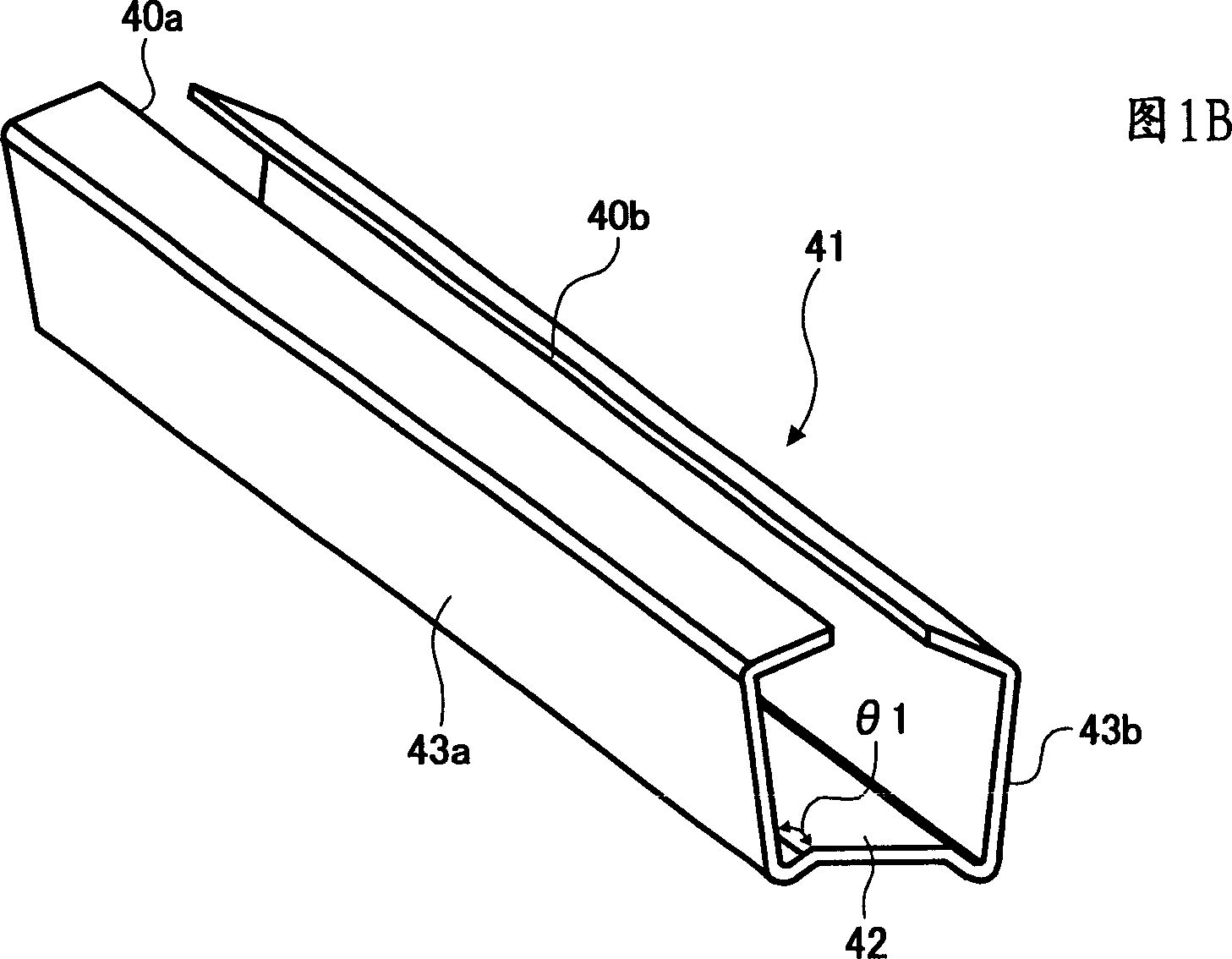

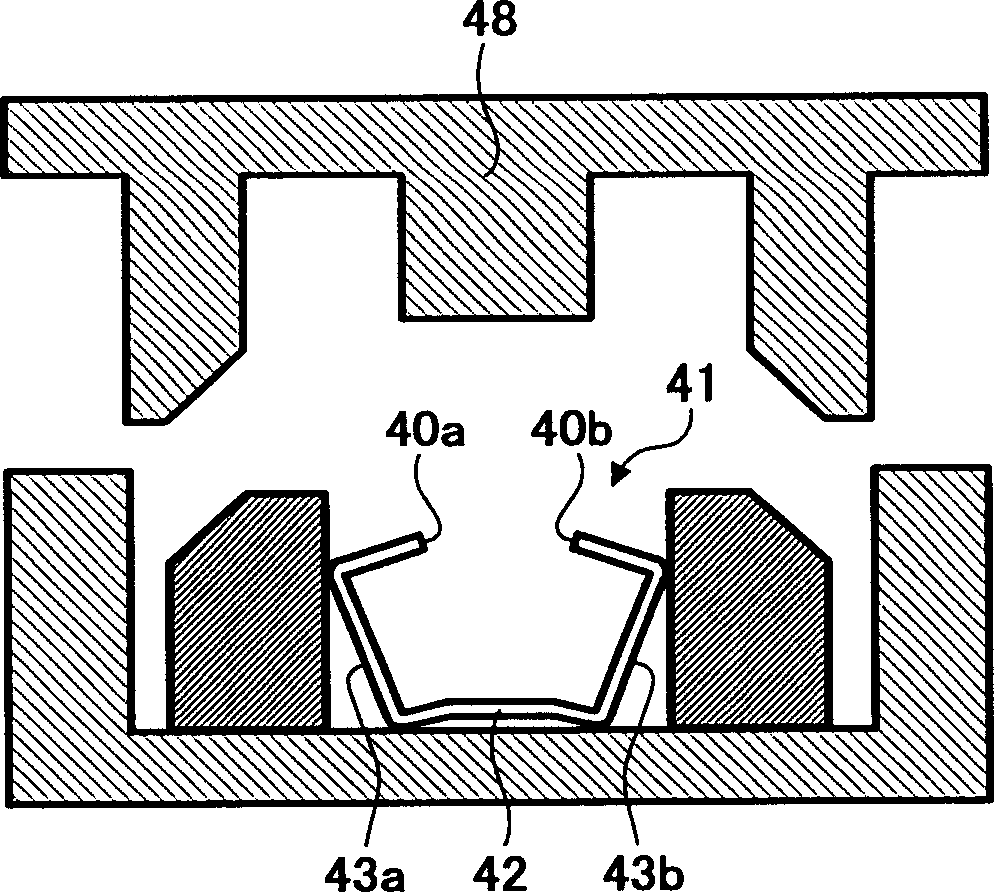

[0086] Fig. 2 is a perspective view of the pipe body involved in the first embodiment of the present invention, image 3 It is a front view showing the pipe body in FIG. 2 . Figure 2 and image 3As shown, the pipe body 1 has a rectangular cross-section, which includes a bottom wall 2, a pair of side walls 3 and 4 adjacent to the bottom wall 2, and an upper wall facing the bottom wall 2. 5, as the four faces corresponding to the sides of the rectangle. The top wall portion 5 is composed of a pair of seam wall portions 5a, 5b. The seam wall portions 5a, 5b are respectively provided with end faces 5c, 5d, and the above end faces 5c, 5d are in close contact with each other. A joint portion 5e that is a seam is formed in the center.

[0087] like Figure 4 As shown, the pipe body 1 is formed by pressing a rectangular metal plate 6 as a raw material. The metal plate 6 includes a pair of sides 6e, 6e parallel to each other. As the material of the above-mentioned metal plate 6, a...

no. 2 example

[0112] In the pipe body manufacturing method involved in this embodiment, in the third processing step, use Figure 19 In place of the pressure forming device 21, a pressure forming device 21a is shown. This pressure forming device 21a is different from the pressure forming device 21 in that it is provided with frictional contact members 27c, 27c with high friction coefficients on the punch surfaces 27b, 27b of the third pressurizing punch members 27, 27, and is different from the pressure forming device 21 in other points. One embodiment is the same, the same part is marked with the same symbol, and the description is omitted.

[0113] like Figure 19 As shown, for the secondary intermediate molded product 14 obtained through the first processing step and the second processing step, as the third processing step, it is first placed in the facing space of the third pressing punch parts 27, 27 28, so that a constituting wall 15 faces downward. If the upper die 23 is lowered f...

no. 3 example

[0120] In the pipe body manufacturing method according to the present embodiment, as shown in FIG. 25 , in the first processing step and the second processing step, the secondary intermediate molded product 14 is formed so that a constituting wall portion 15 and an adjoining surface constitute the wall portion. The angle θ4 formed by 16a, 16b = 90°. In the third processing step, instead of the pressure forming device 21, the pressure forming device 21b is used. This pressure forming device 21b is different from the pressure forming device 21 in that the protrusions 27e, 27e are provided on the punch surfaces 27b, 27b of the third pressurizing punch members 27, 27, and the other is the same as the first embodiment. The same part is marked with the same symbol, and the description is omitted.

[0121] As for the secondary intermediate molded product 14 obtained through the first processing step and the second processing step, as a third processing step, it is placed in the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com