Vehicle eddy current brake experiment unit

An experimental device, eddy current braking technology, applied to vehicle components, electric braking systems, electric vehicles, etc., can solve problems such as inability to simulate operating modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

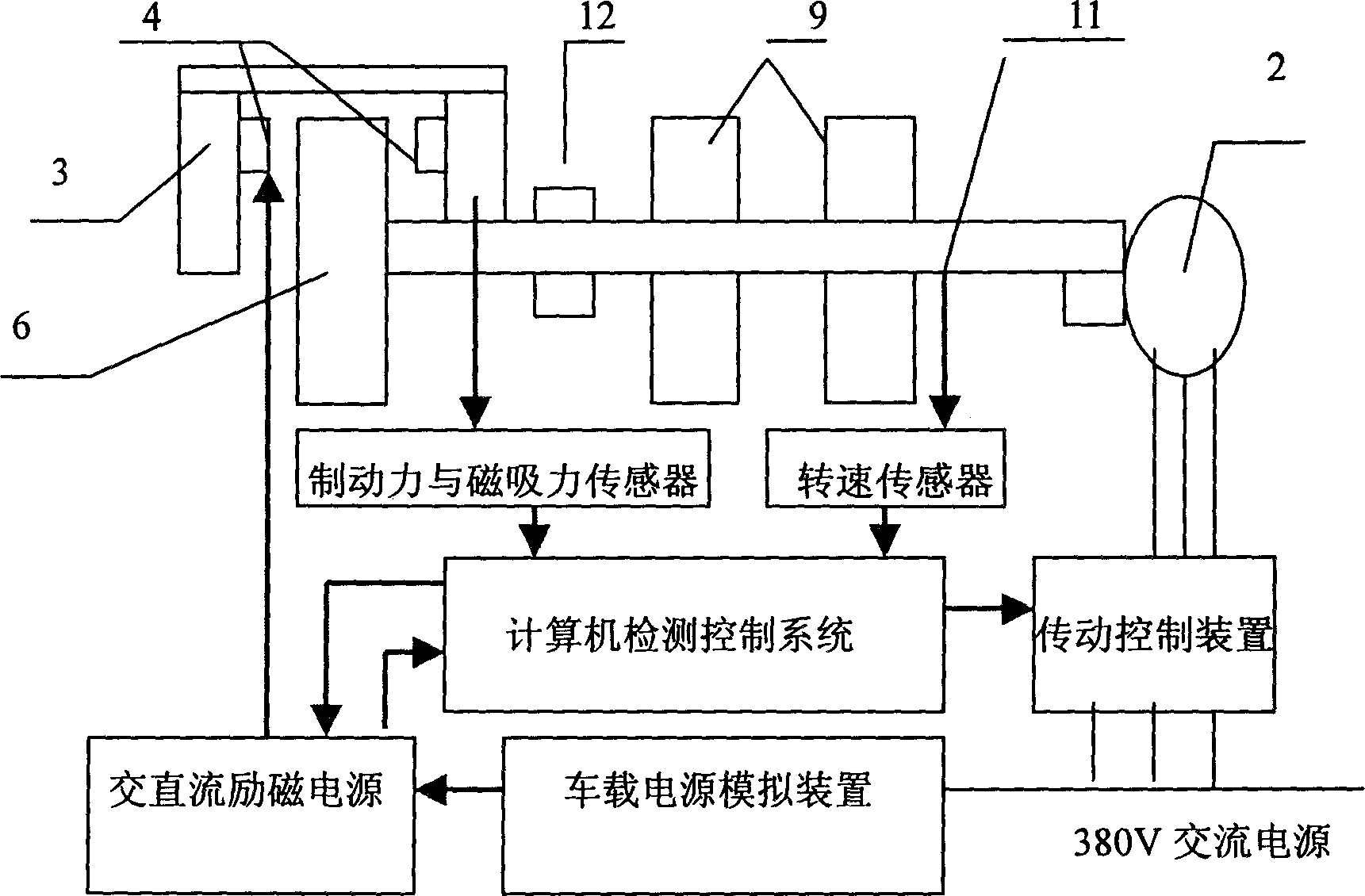

Method used

Image

Examples

Embodiment Construction

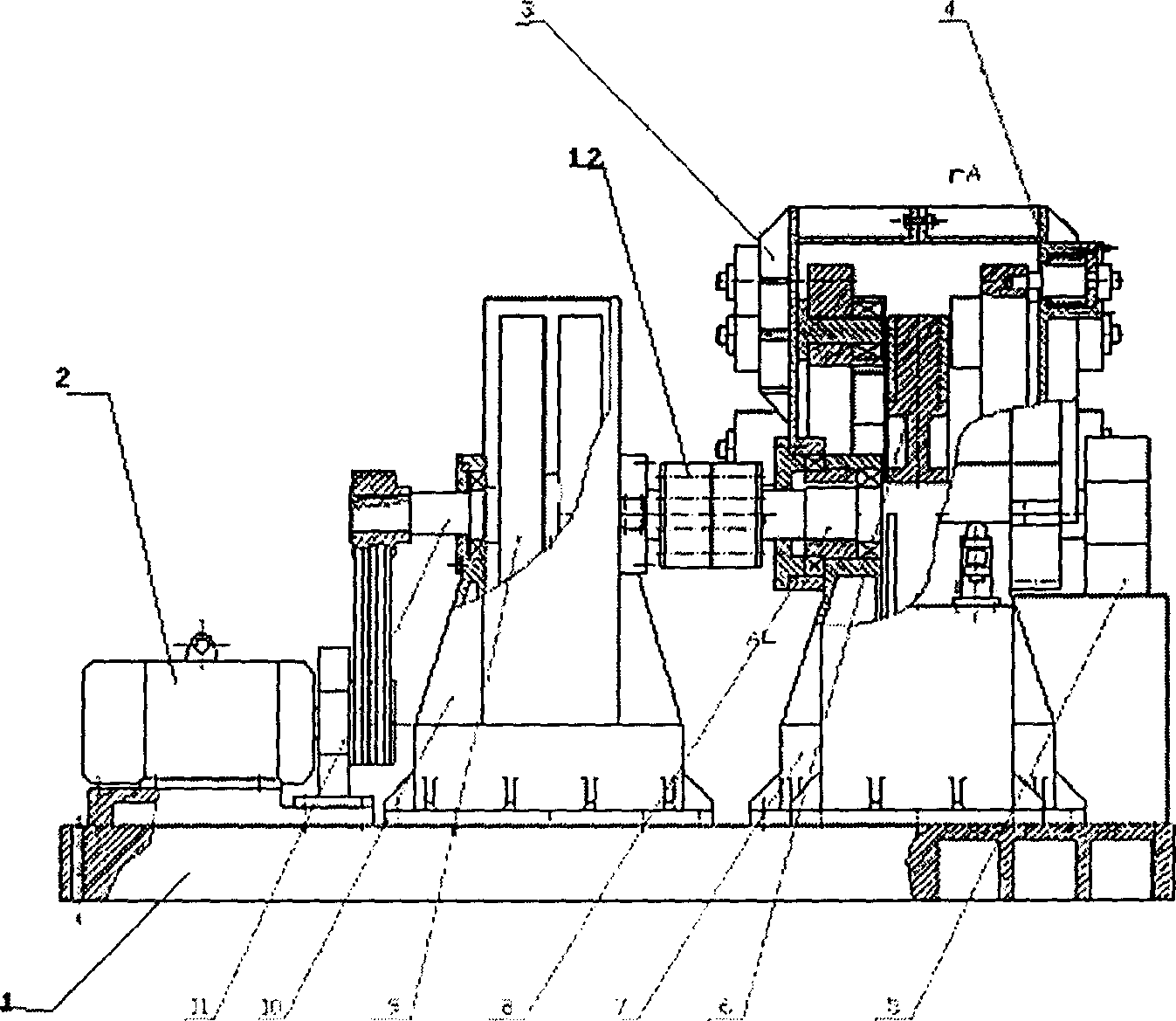

[0026] The present invention is further described below by way of examples.

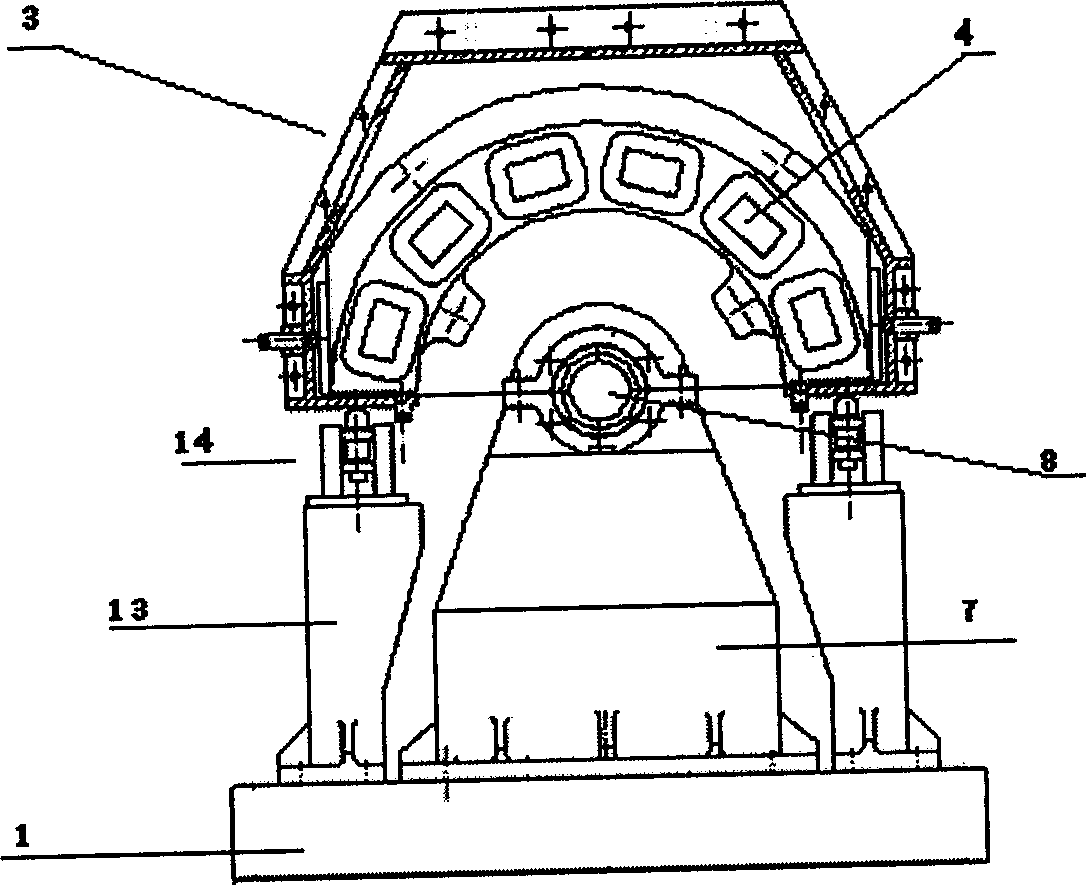

[0027] In the embodiment, the track test wheel has a diameter of 1380 mm and a thickness of 200 mm; the inertia wheel has a diameter of 1215 mm and a thickness of 150 mm. The speed is about 1470 rpm, and the outer edge speed of the track wheel test is 350km / h. The track wheel test consists of a wheel body and an induction board (a guide rail simulation board on a maglev line). 12 magnetic poles, 12 damping springs, and 10 magnetic attraction sensors are installed on the magnetic pole installation support device 3 . There are also four brake force sensors.

[0028] Maximum moment of inertia: ∑J 实际 =J 轨道轮 +2J 惯性轮 +J 零 =934.34N·m·s 2 . The size of the magnetic pole core is 190 x 250 x 90 mm long; the magnet winding is 350 turns, and the ampere-turns are 110 x 350 x 2 x 6. Dimensions of each electromagnet: 260mm×204mm; iron core 90×150mm. The maximum vertical magnetic attraction is greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com