Techique of high thermal efficiency internal combustion engine with long pistion stroke and zero side pressure and devices

An internal combustion engine and high thermal efficiency technology, applied in mechanical equipment, machines/engines, etc., can solve problems such as life crisis and low thermal efficiency, and achieve the effect of ensuring thermal efficiency and reducing dependence or independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

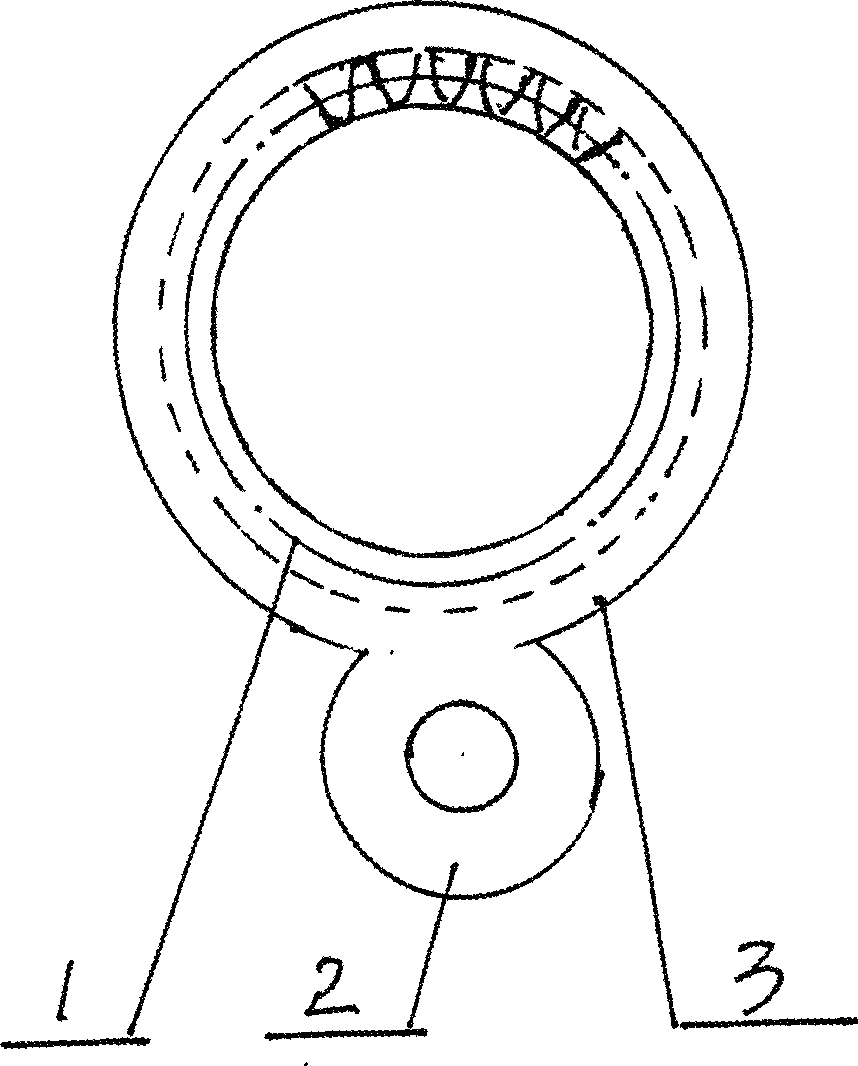

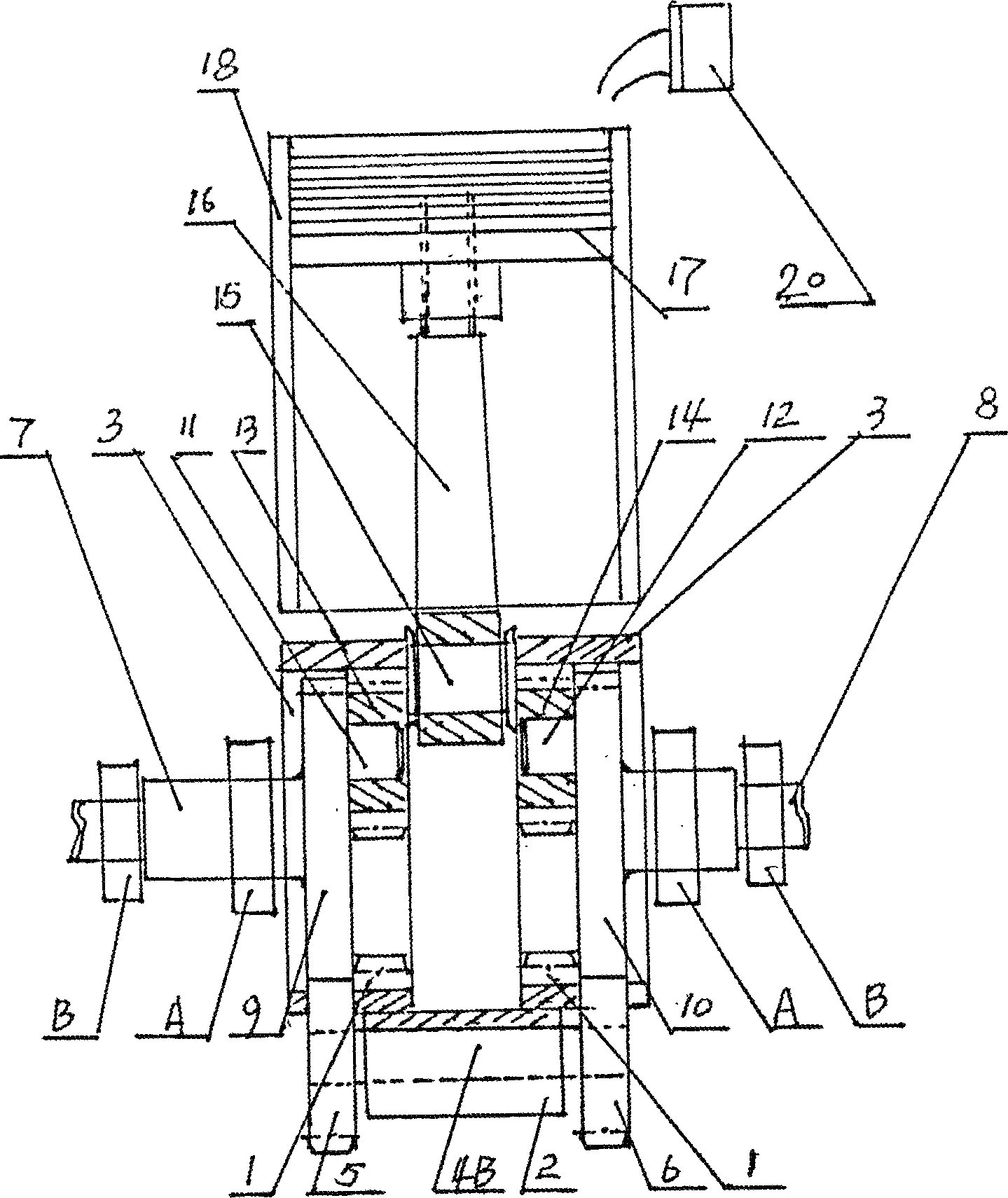

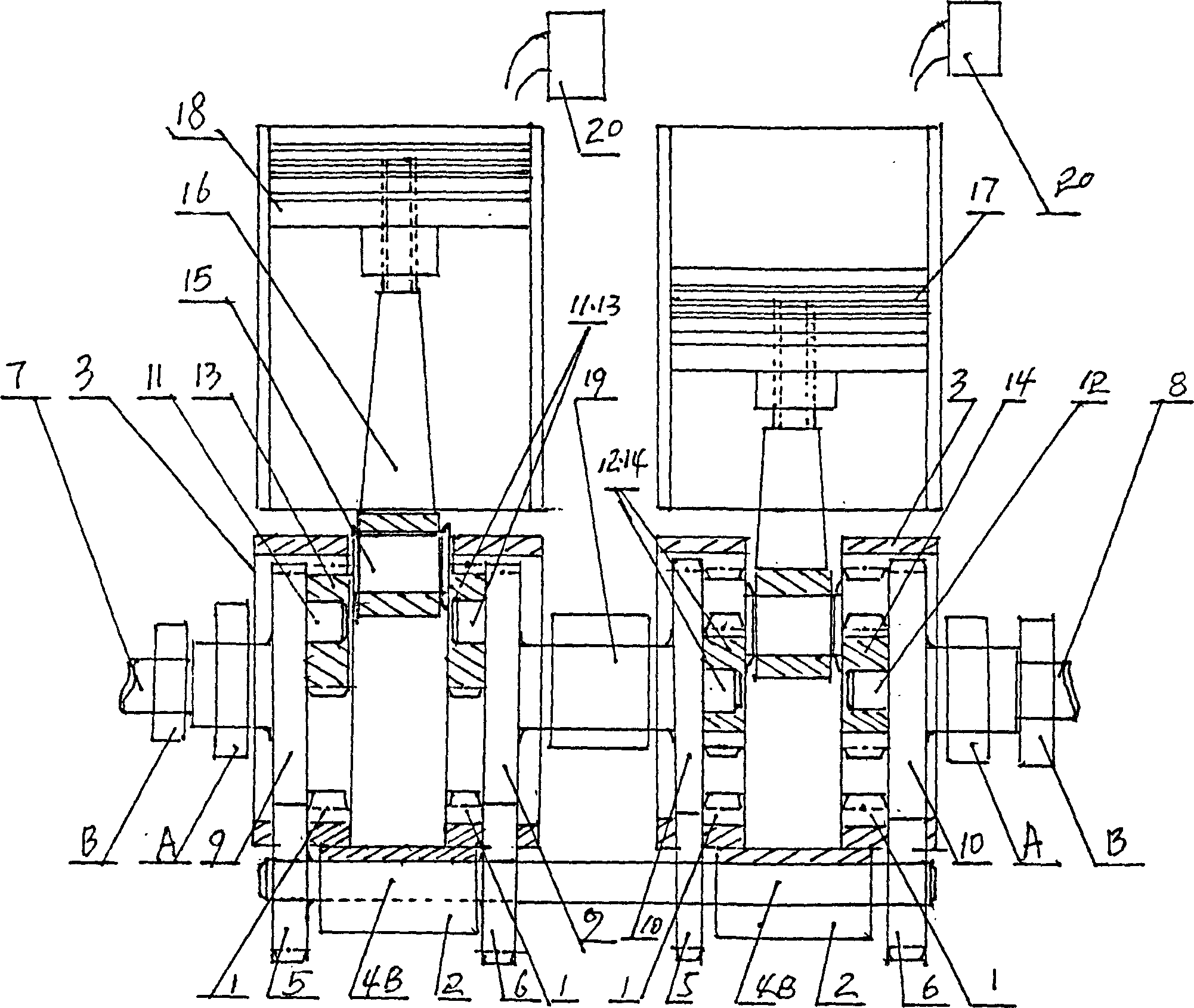

[0019] figure 1 , figure 2 It is a technical solution for a single-cylinder internal combustion engine. 1 in the figure is a double-unit fixed-circle internal gear seat, which is integrated with the force-taking synchronous gear bearing seat 2, combined with the conjoined seat 3, a synchronous shaft 4A is set on the synchronous gear bearing seat 2, and synchronous gears are arranged at both ends of it. 5, 6, fixedly install the conjoined seat group composed of fixed circle internal gear seat 1, synchronous gear bearing seat 2, conjoined seat 3, synchronous shaft 4A, synchronous gear 5, 6 under the cylinder 18 feet, so that the double conjoined The center of the fixed circle internal gear seat 1 is to the bearing seat center of the original crankshaft. Set the left and right output shafts 7, 8 with double bearings or bearing bushes and bushings, set conjoined co-force toothed discs 9, 10 at their inner ends, and set conjoined primary eccentric shafts or The holes 11 and 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com