Probe memory device and method for detecting data in probe memory device

A probe storage and probe technology, used in data recording, measurement devices, information storage, etc., to achieve the effect of low power consumption and improved reading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

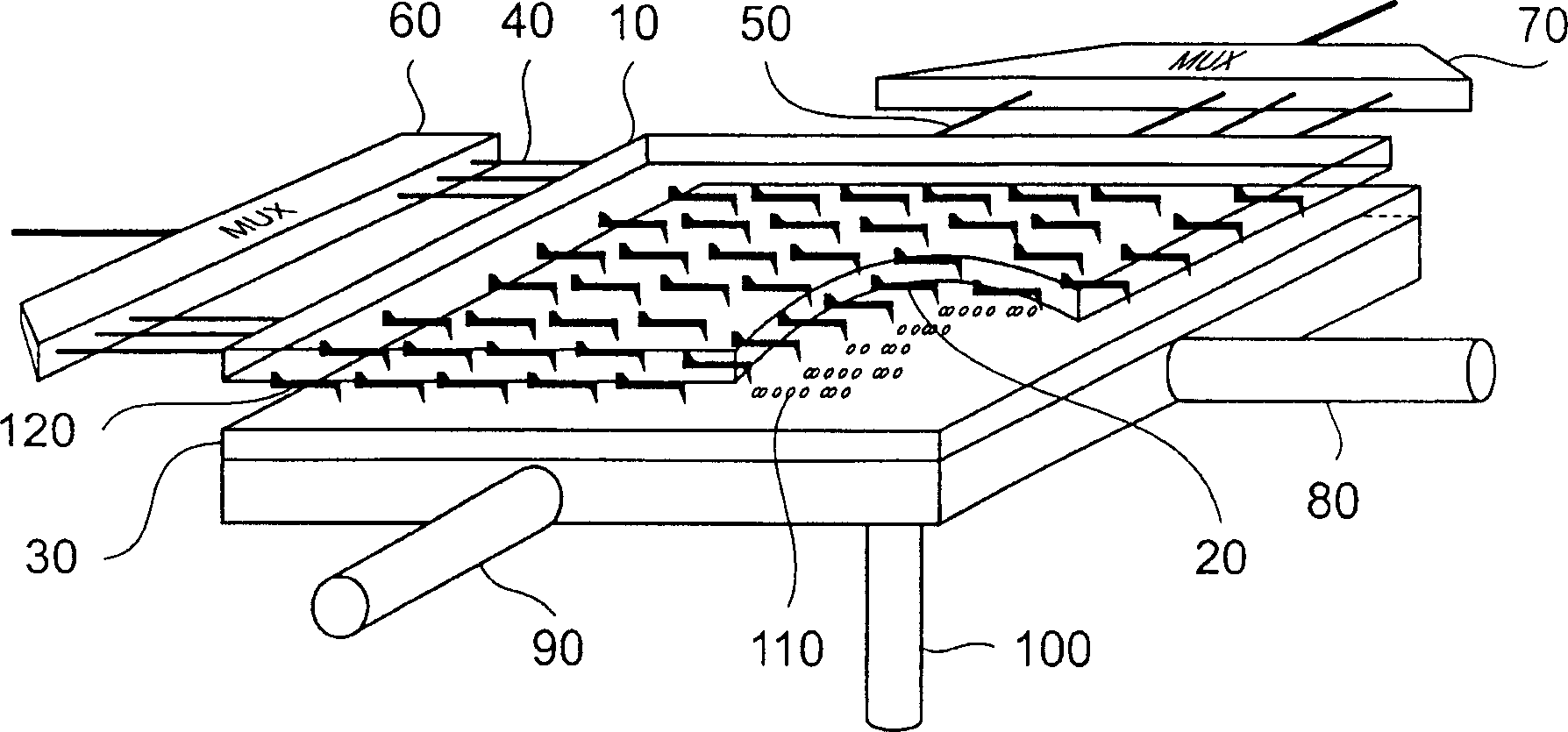

[0027] First refer to figure 1, one example of a probe memory device embodying the present invention includes a substrate 10 having a two-dimensional array 120 of probe cantilever sensors 20 facing a storage surface 30 . The cantilever 20 is connected to a row conductor 40 and a column conductor 50 . Each suspension 20 is addressed by a different combination of row 40 and column 50 conductors. Row conductors 40 are selectively addressed by row multiplexers 60 . Similarly, column conductors 50 are selectively addressed by column multiplexers 70 . The storage surface 30 is mounted on a scanning mechanism consisting of an x-position transducer 80 , a y-position transducer 90 and a z-position transducer 100 . In operation, z-position transducer 100 moves storage surface 30 closer to or away from array 120 . The x-position transducer 80 and the y-position transducer 90 move the storage surface 30 in an orthogonal direction relative to the array 120 and in a plane parallel to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com