Ballast circuit for operating a discharge lamp

A ballast and discharge lamp technology, applied in the field of electronic discharge lamp ballasts, can solve problems such as complex circuit configuration and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

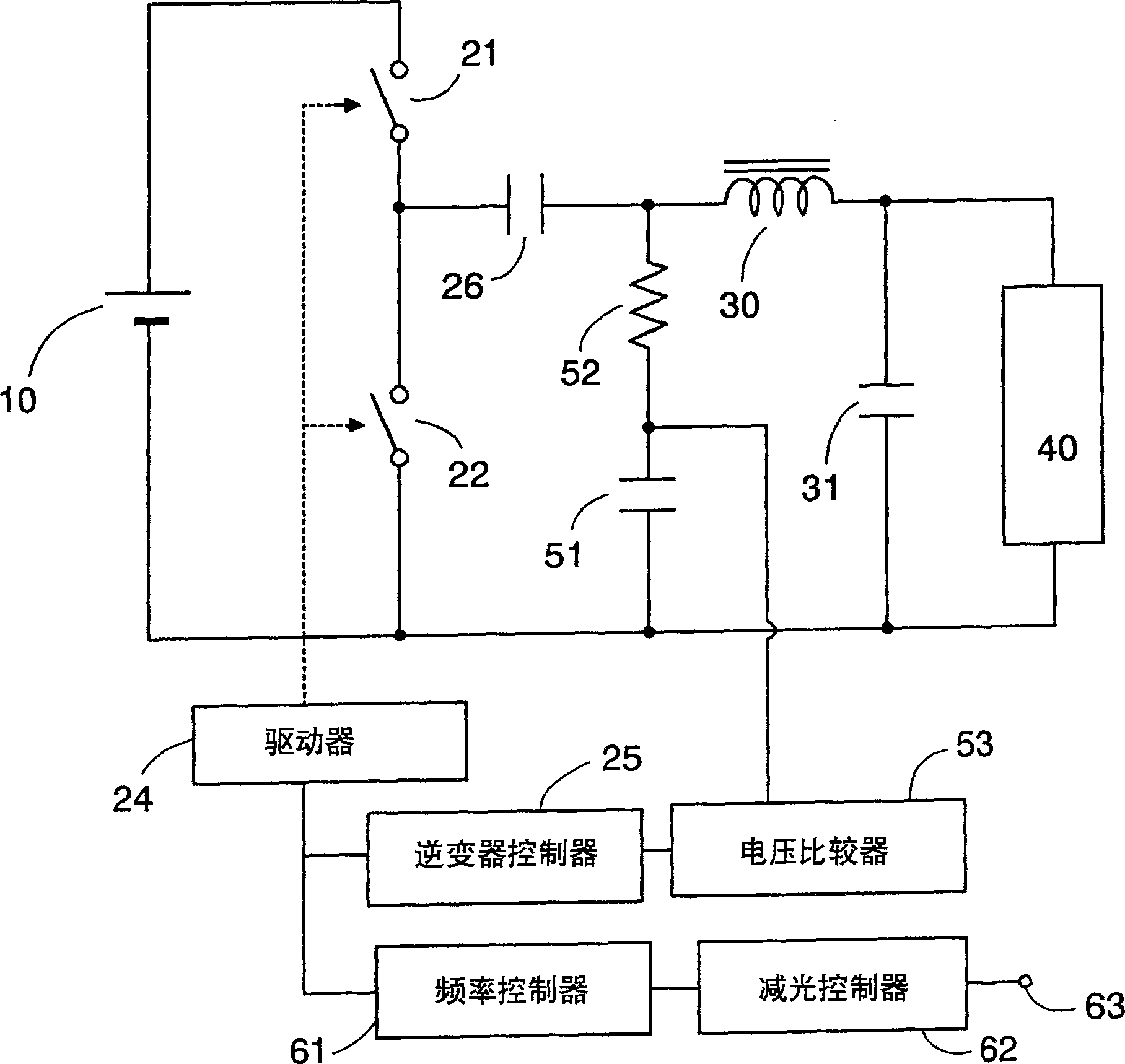

[0014] now refer to figure 1 , shows a ballast circuit for operating a discharge lamp according to a preferred embodiment of the present invention. The ballast circuit includes a DC voltage power supply 10 and a pair of first and second inverter switches 21 and 22, the DC voltage power supply 10 provides a constant DC voltage, and a pair of first and second inverter switches 21 and 22 across It is connected in series on the DC voltage source 10 and driven by a driver 24 to be switched on and off alternately under the control of an inverter controller 25 . The first inverter switch 11 defines a high-side switch, while the second inverter switch 12 defines a low-side switch, one end of which is connected to the ground of the circuit. The circuit also includes a series of resonant circuits composed of an inductor 31 and a capacitor 32, the inductor 31 and the capacitor 32 are connected in series with the blocking capacitor 26 across the second inverter switch 12, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com