Chair with heating means and producing method thereof

A manufacturing method and heating device technology, which are applied to electric heating devices, vehicle seats, seat heating/ventilating devices, etc., can solve the problems of conductor 102 disconnection, difficulty in grouping, insufficient strength, etc. Durability, effect of uniform seat temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

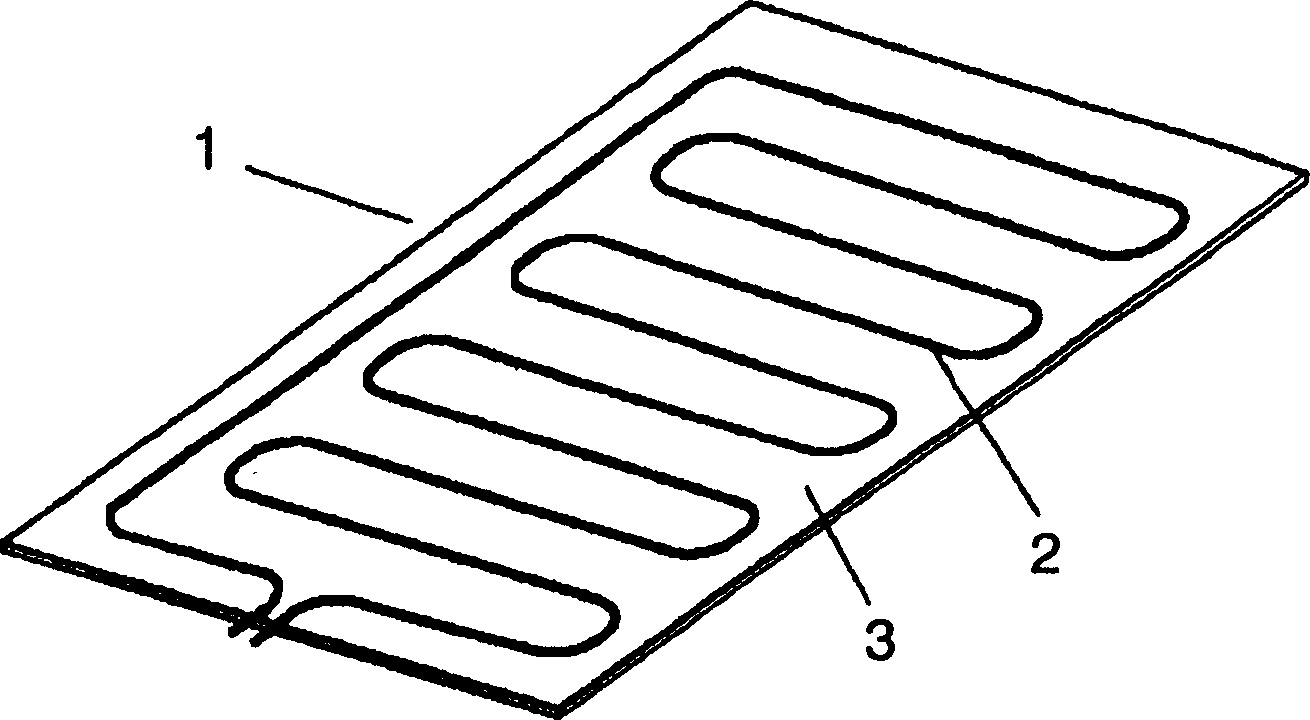

[0042] figure 1 It is a perspective view of a planar heating element (heating element) of the present invention, which is formed by fixing a linear heating element to a base fabric made of heat-sealable material in a predetermined wiring pattern. exist figure 1 Among them, the linear heating element 2 is fixed on the base fabric 3 made of heat-sealing material in a predetermined pattern by an adhesive 7 to form a planar heating element 1 .

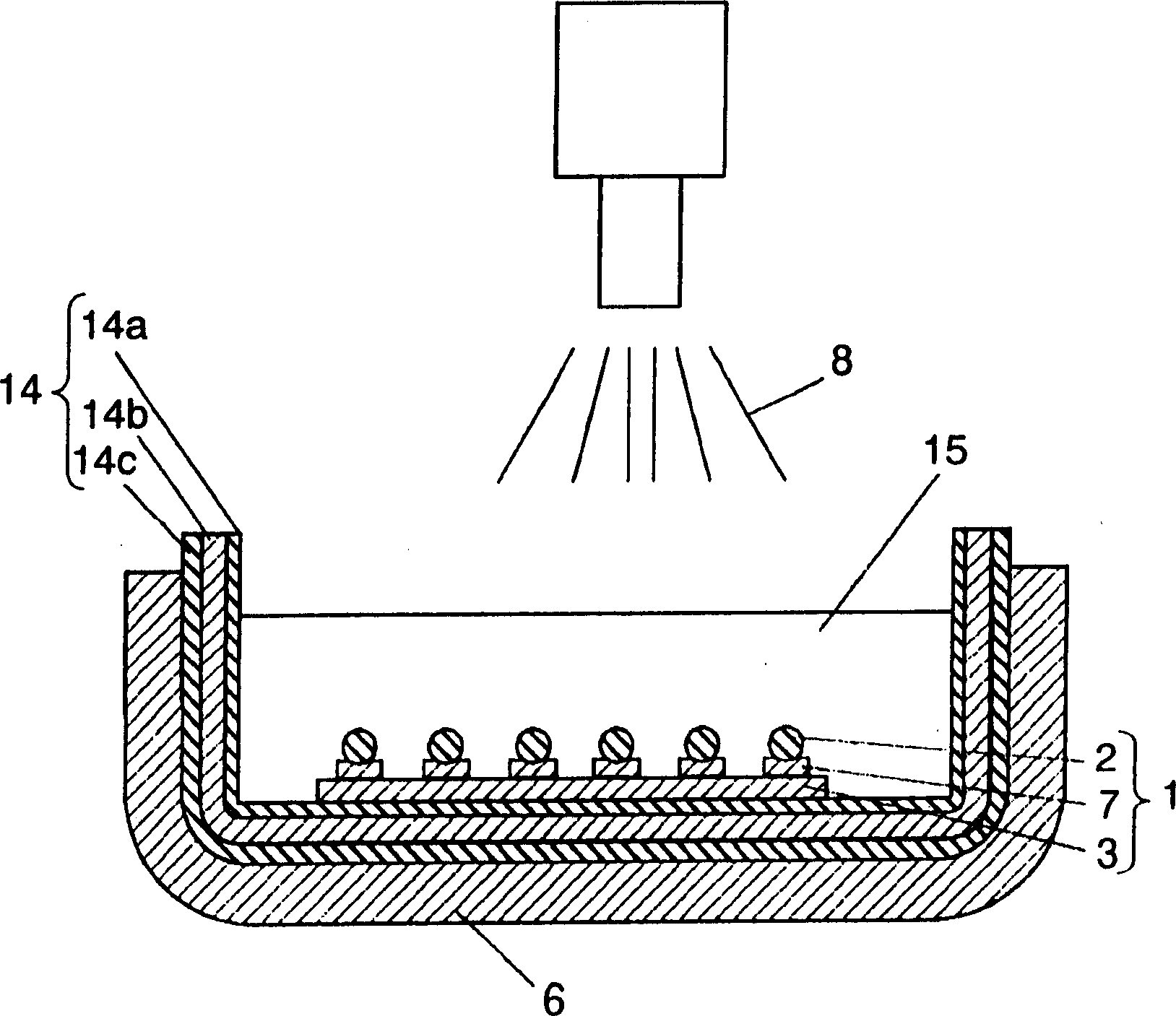

[0043] below, through figure 2A method of manufacturing a seat with a heating device using the planar heating element 1 of this embodiment will be explained. Such as figure 2 As shown, the skin material 14 includes: a skin 14c made of leather, cloth, etc., a surface cushion 14b made of foamed urethane, a cover material 14a made of polyethylene film or woven cloth coated with impregnation prevention materials. After the planar heating element 1 is fixed on the above-mentioned cover material 14a, the seat of the skin 14 is placed in ...

Embodiment 2

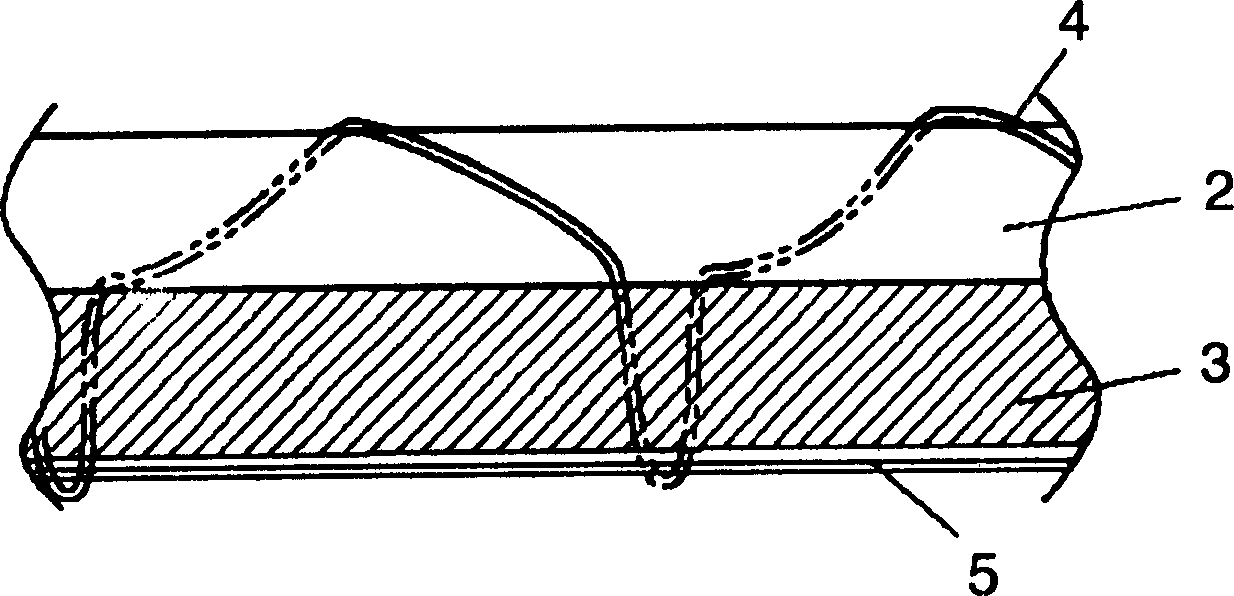

[0049] image 3 It is a sectional view of the planar heating element of the second embodiment. Such as image 3 As shown in , the linear heating element 2 is fixed on the base fabric 3 by sewing. Generally, the method of arranging the linear heating element 2 on the base fabric 3 is to use an adhesive. However, if an adhesive is used, the heat-sealing material constituting the base fabric 3 will melt under the action of the adhesive, and the fixing strength around the linear heating element 2 may decrease. In such a case, by fixing the linear heating element to the base fabric 3 by sewing, it is possible to avoid adverse effects of the adhesive on the heat-sealed material. image 3 A side view of the linear heating element 2 fixed by sewing is shown, and the linear heating element 2 is fixed on the base fabric 3 made of heat-sealing material by the upper thread 4 and the lower thread 5 .

[0050] In addition, if at least one of the upper thread 4 or the bottom thread 5 for...

Embodiment 3

[0054] Figure 4 It is a schematic diagram of a linear heating element with a heat-welding layer on its periphery. Figure 4 Among them, in the linear heating element 9 of this embodiment, the heat-sealing layer 11 is provided on the periphery of the heating element 10 . As the thermally welded layer 11 melts and solidifies when the planar heating element is thermally welded to the skin, the strength of fixing the linear heating element to the skin can be increased.

[0055] In addition, it is preferable to use materials such as polyester, nylon, polyolefin, and polyamide as the material constituting the heat-sealing layer 11, but these are not restrictive.

[0056] In addition, in the description of this embodiment, the method of fixing the linear heating element on the base cloth adopts the method of using adhesive and sewing, but the method of fixing the linear heating element on the base cloth is of course It is not limited to these.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com