Machining manufacture of colour articles

A technology for processing and manufacturing articles, which is applied in the field of processing and manufacturing of colored articles, and can solve problems such as easy wear, falling off, coating, staining and misalignment of the color layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below according to the embodiment shown in accompanying drawing, describe in detail:

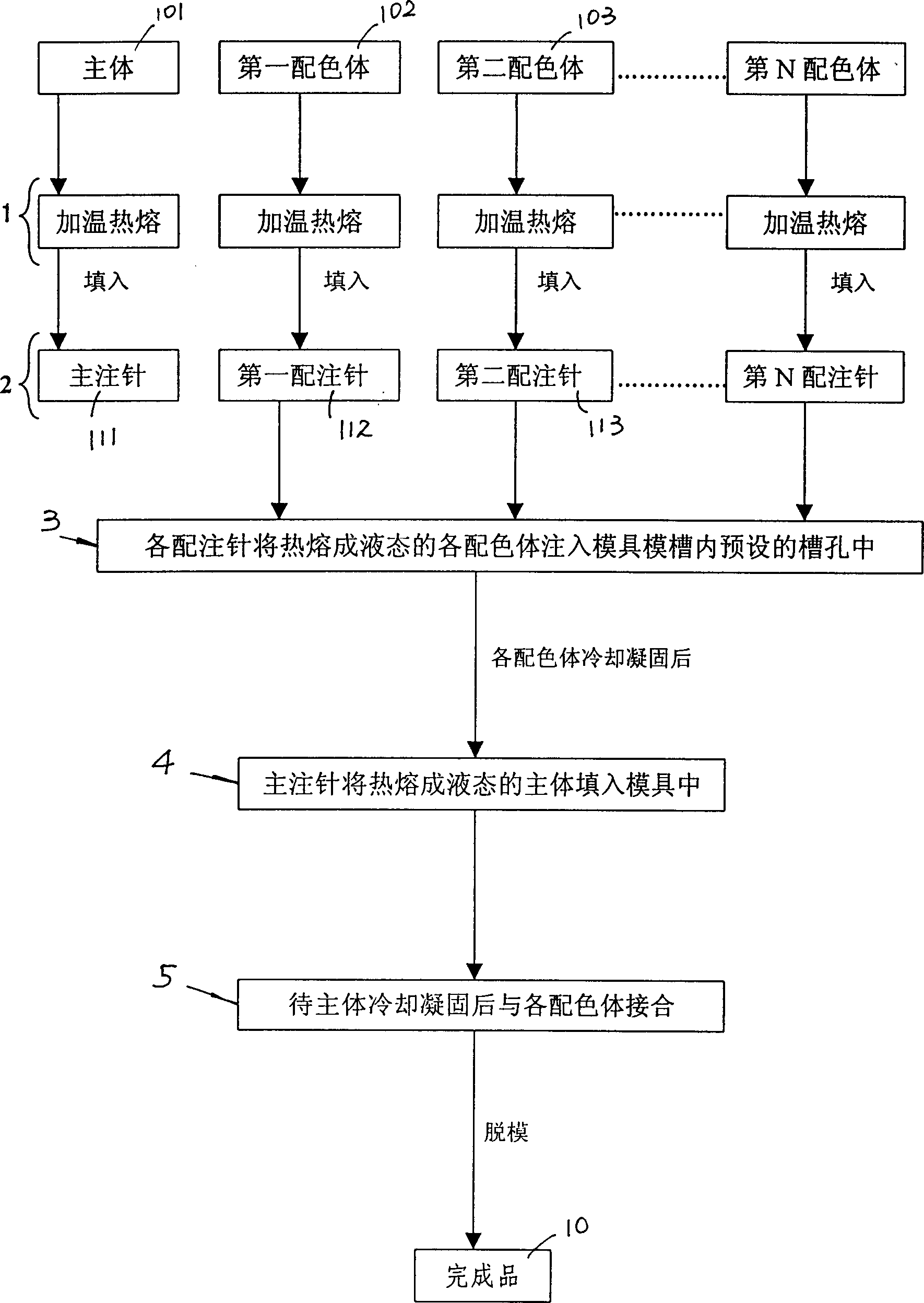

[0051] Such as figure 1 Shown is the flow chart of the processing and manufacturing method of the present invention, and the manufacturing method given in the figure is: step 1, step 2, step 3, step 4 and step 5. Wherein the raw material that this method adopts is to have the material of the physical characteristic that can melt into fluid state after being heated, and can keep in solidified state under normal temperature, and its specific manufacturing method is as follows:

[0052] Step 1 is to heat and melt the main body 101 and each color matching body 102, 103..., so that the main body 101 and each color matching body 102, 103... change from a solid state to a fluid state, for example: plastics with various colors, or plastics with Foodstuffs of various colors.

[0053] Step 2: Fill the hot-melted main body 101 into the main injection needle 111, and at the same time fill the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com