Socket discs and connecting bars components and their use combined with gantry scaffold

A technology of portal scaffolding and application method, applied in the field of construction, can solve the problems of poor stability, inability to directly connect and reinforce portal scaffolds, transportation, inconvenient and flexible use, etc., so as to improve construction stability, simple structure and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

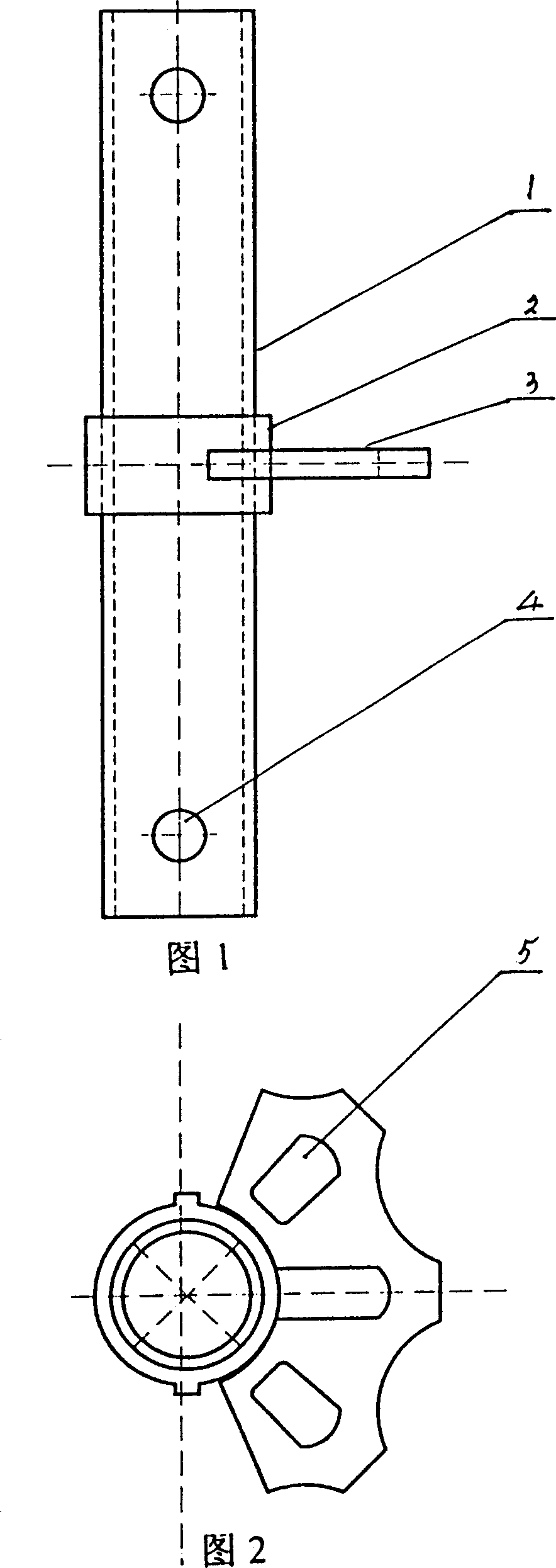

[0015] The ferrule parts of the present invention are produced. First, make a 300mm long steel connecting rod 1 with fixing holes 4 at both ends, and press and fix the positioning collar 2 in the middle of the steel connecting rod; The hole 5 should be made into a rectangle, the width dimension should be greater than the thickness of the wedge pin, and the two short sides of the jack 5 are arc-shaped; then, the insert plate 3 is welded and fixed on the steel collar 2, and the production of the parts is completed.

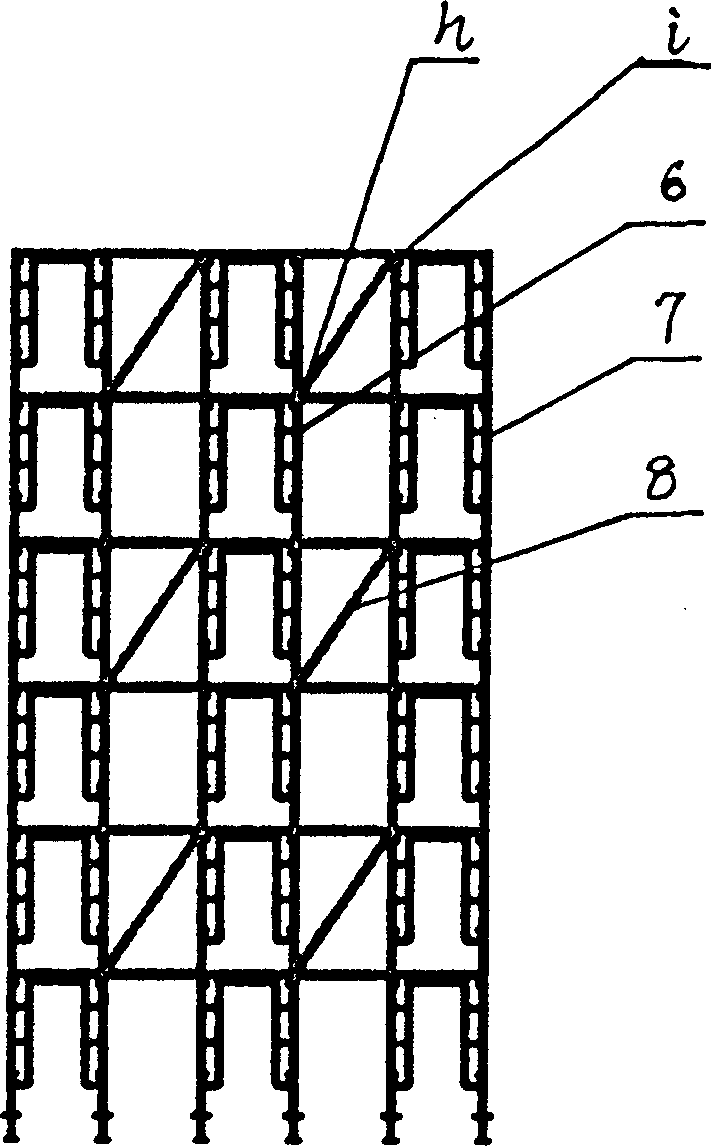

[0016] In the combined application of portal scaffolding and plug-in scaffolding, first insert one end of the connecting rod 1 at the connection part into the tube hole of the main column of the portal scaffolding to be reinforced, and nail the pin through the fixing hole 4 to fix it firmly. image 3 The middle h and i are the parts where the main column is assembled with the connecting rod; through the connecting plug and connecting rod of the jack 5, the first grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com