Method for transforming energy and vortex tube for carrying out said method

A vortex tube, a technology for converting energy, used in the field of electric power industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

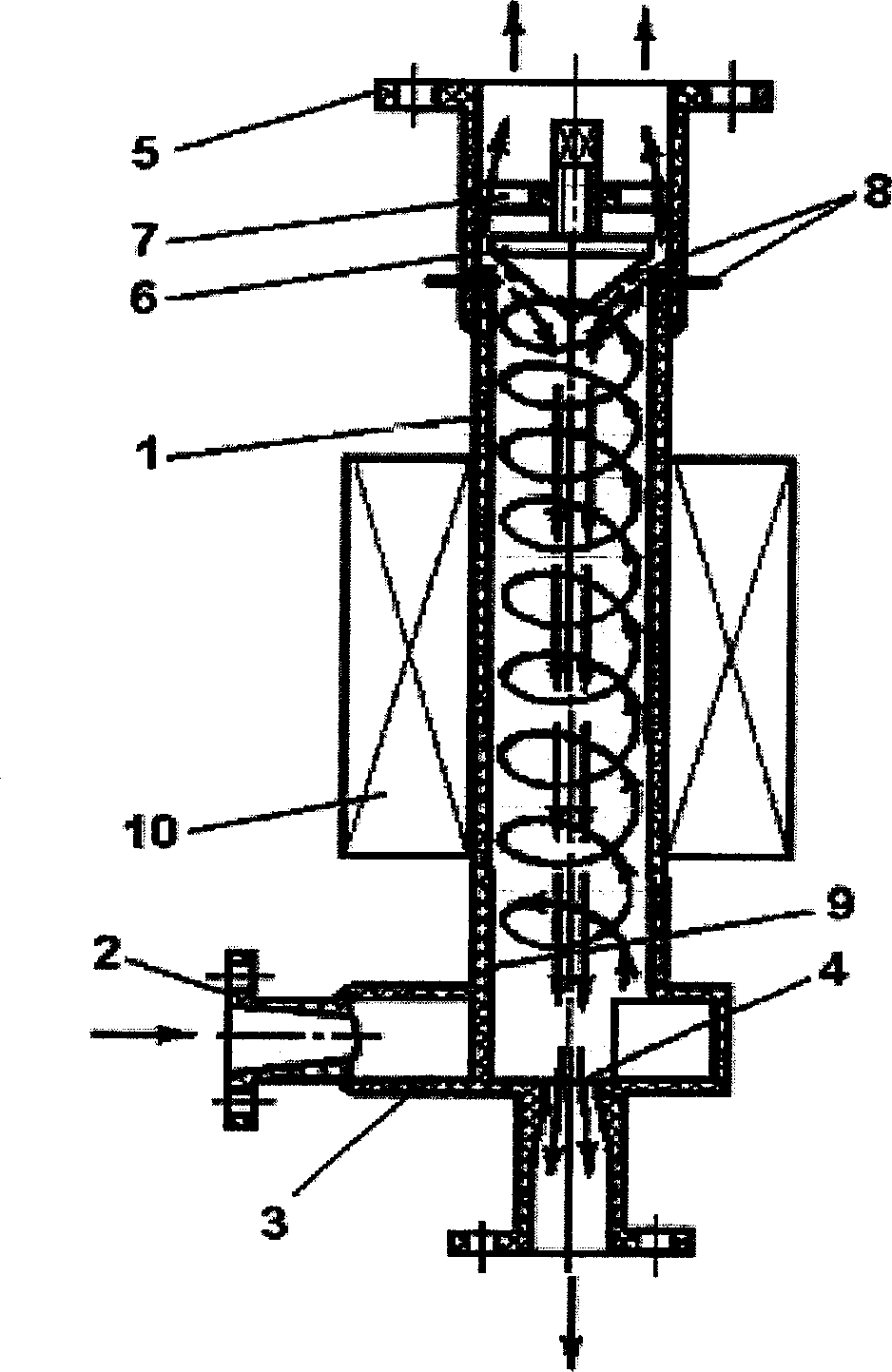

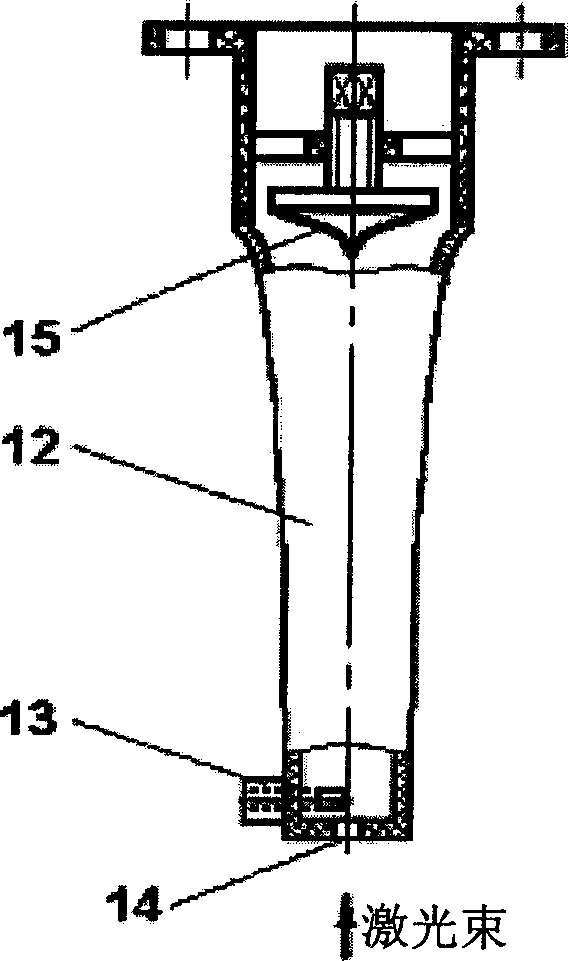

[0028] The present invention will be described with reference to an embodiment of a thermoelectric water generator according to the Gritskevich vortex tube.

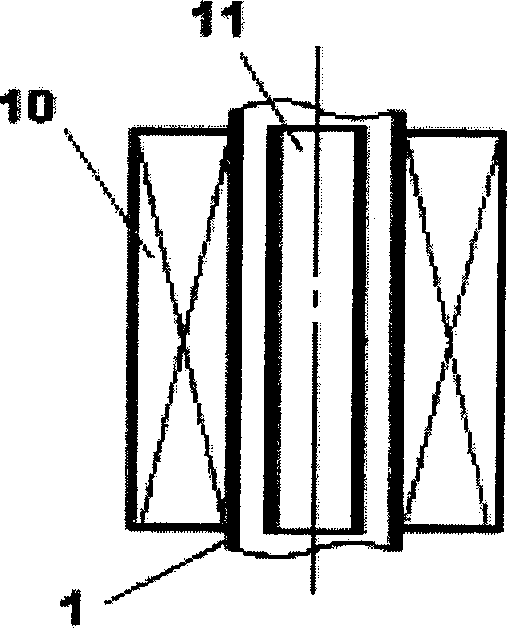

[0029] Such as figure 1 As shown, the vertically placed cylindrical thermoelectric generator includes a tube shell 1 with a cold part, which is converted to a volute swirler 2 through an injection port 3 and a partition plate with an opening 4. The thermal component includes an outlet nozzle 5, an adjustment cone 6 with a shaft adjustment device 7, and a pair of electrodes 8 extending horizontally along the circumference of the gap between the tube shell 1 and the adjustment cone 6. The inside of the tube case 1 is coated with a thin layer of barium titanate (TiBa), and the outside has an electromagnetic winding 10. The tube shell 1, the spiral swirler 2, the adjusting cone 6 and the nozzles 3 and 5 are made of plastic and separated from the ground.

[0030] The cold water flow entering the cold part through the nozzle 3 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap