Feedback regulator and process of large load, double hydraulic cylinder and cychronous operation

A technology of feedback adjustment and synchronous operation, applied in fluid pressure actuators, measuring devices, instruments, etc., can solve problems such as complex devices and operating processes, achieve force balance, simple adjustment devices and processes, and reliable test results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

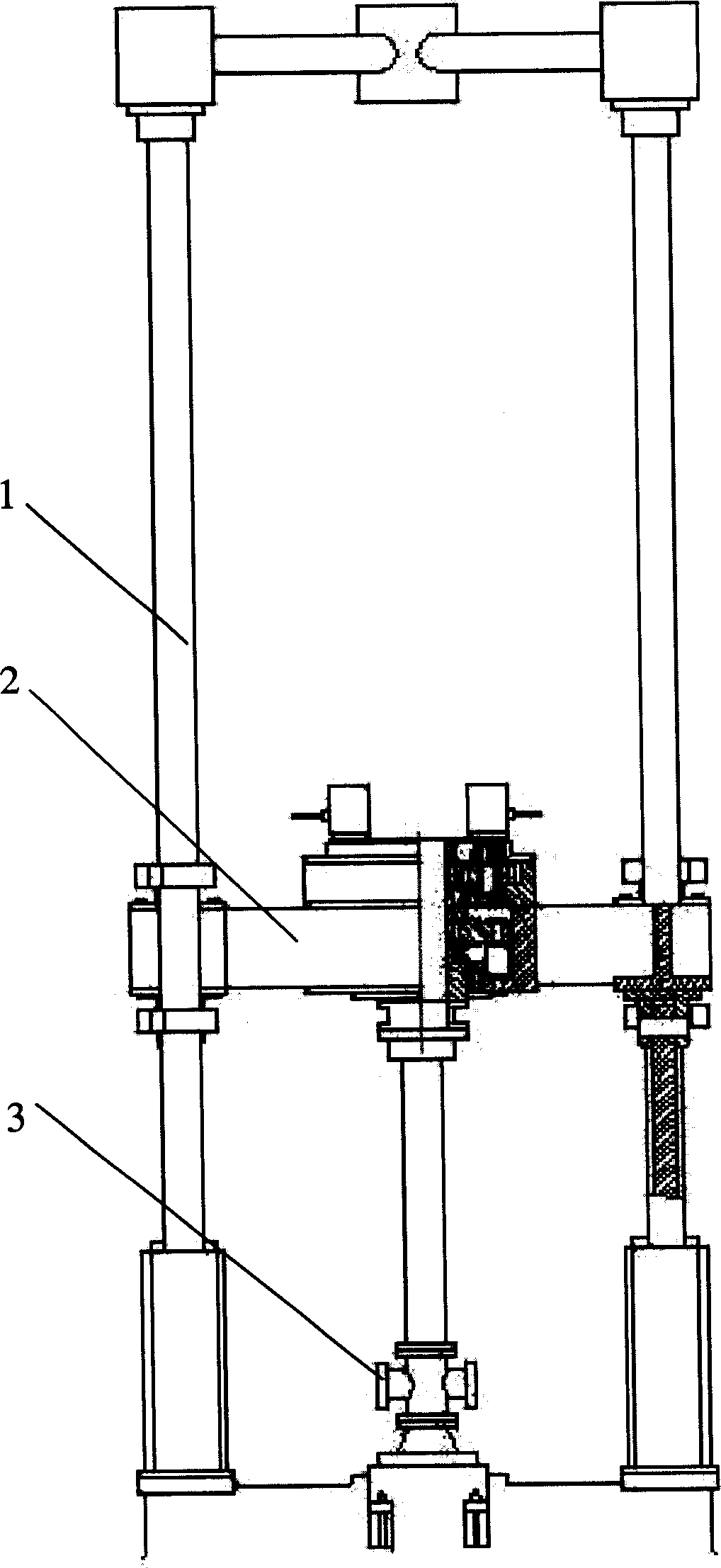

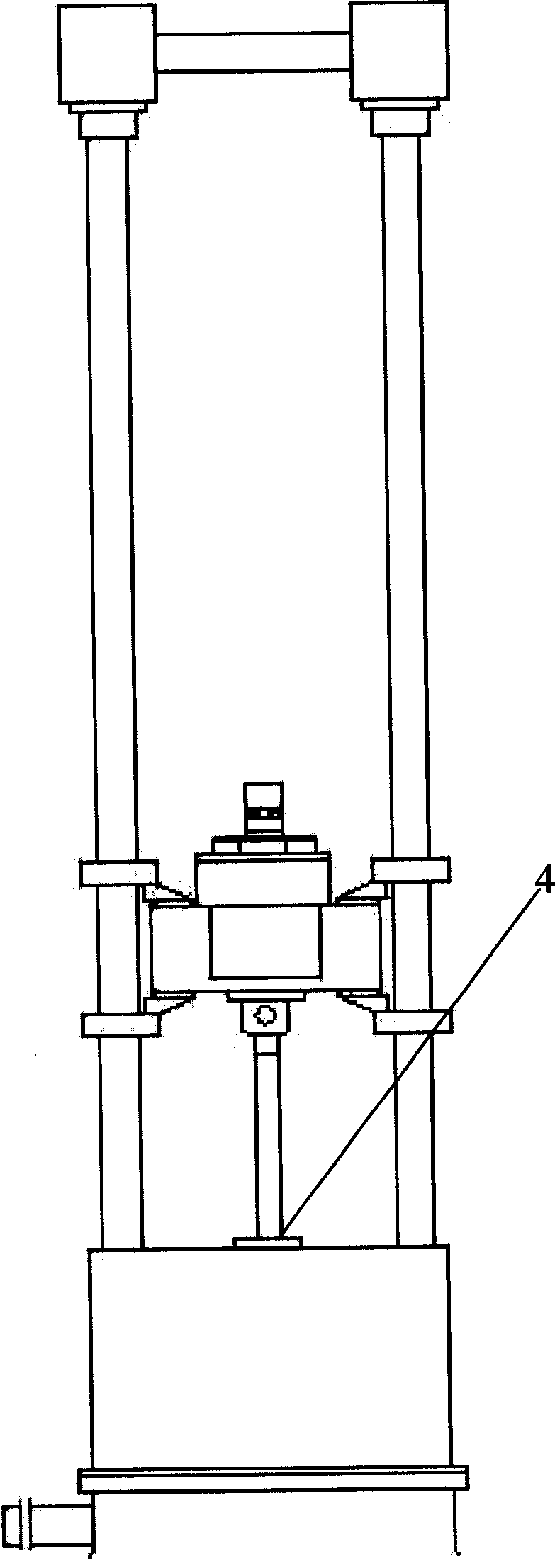

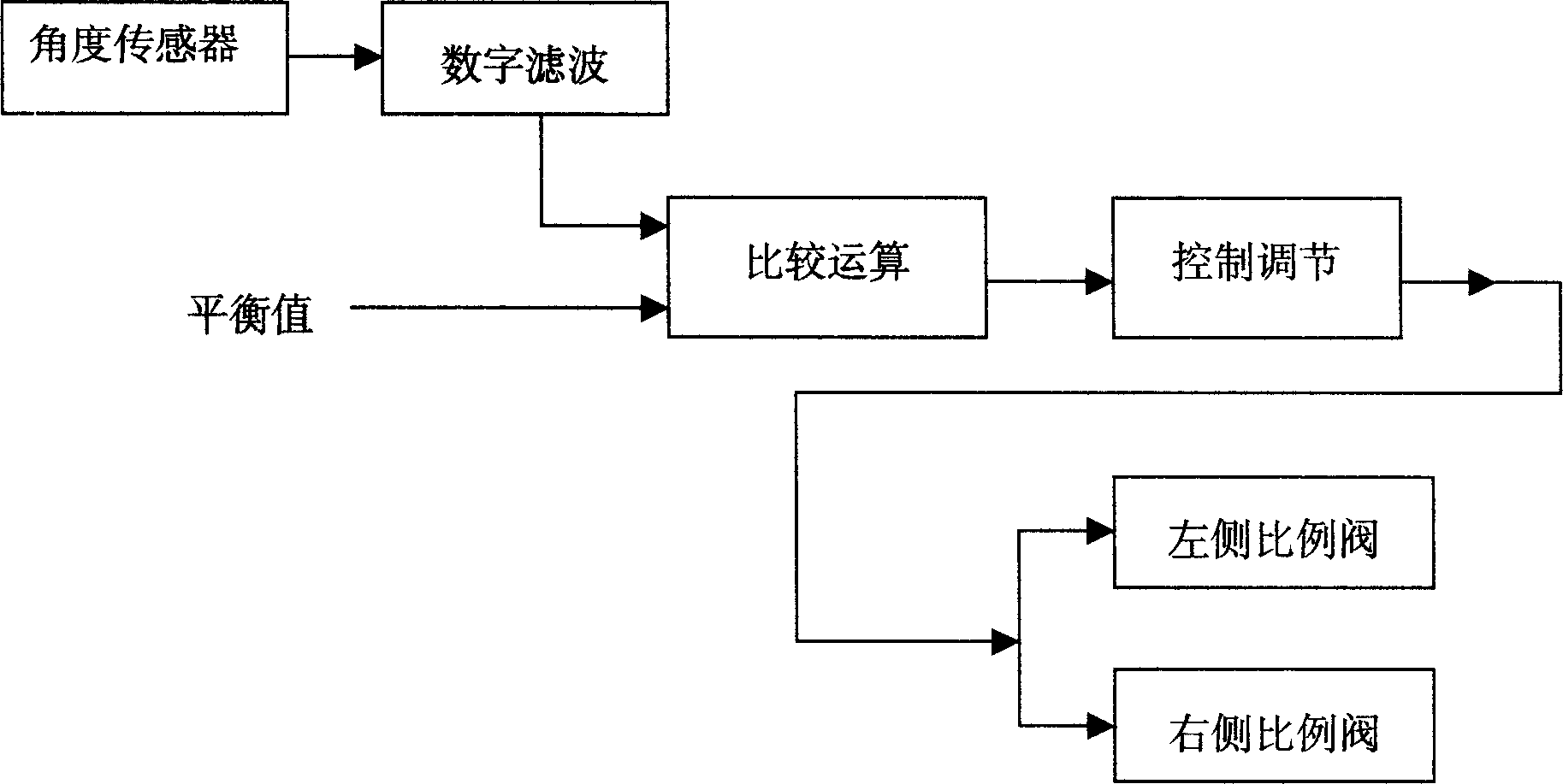

[0018] Feedback adjustment device and process for synchronous operation of large-load dual hydraulic cylinders, which is composed of an inclination sensor installed on a traveling beam, a synchronous controller with a specific program, and two proportional regulating valves installed on the hydraulic cylinder pipeline The feedback adjustment structure realizes the dynamic and synchronous control of the hydraulic cylinders on both sides of the downhole tool detection device under heavy load conditions. The process is:

[0019] Depend on figure 1 and figure 2 As shown, the traveling beam moves up and down along the four guide columns with a stroke of 4m. The movement of the traveling beam depends on the drive of the hydraulic cylinders on both sides. The distance between the hydraulic cylinders on both sides is 2.5m. Tool, when the traveling beam moves downward, it applies pressure to the tool. The design pressure of this system is 300kN. When the traveling beam moves upward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com