Radiator and its producing method

A manufacturing method and radiator technology, which are applied to instruments, electric solid state devices, semiconductor devices, etc., can solve the problem of high processing difficulty, and achieve the effects of saving manufacturing costs, improving heat dissipation area, and improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

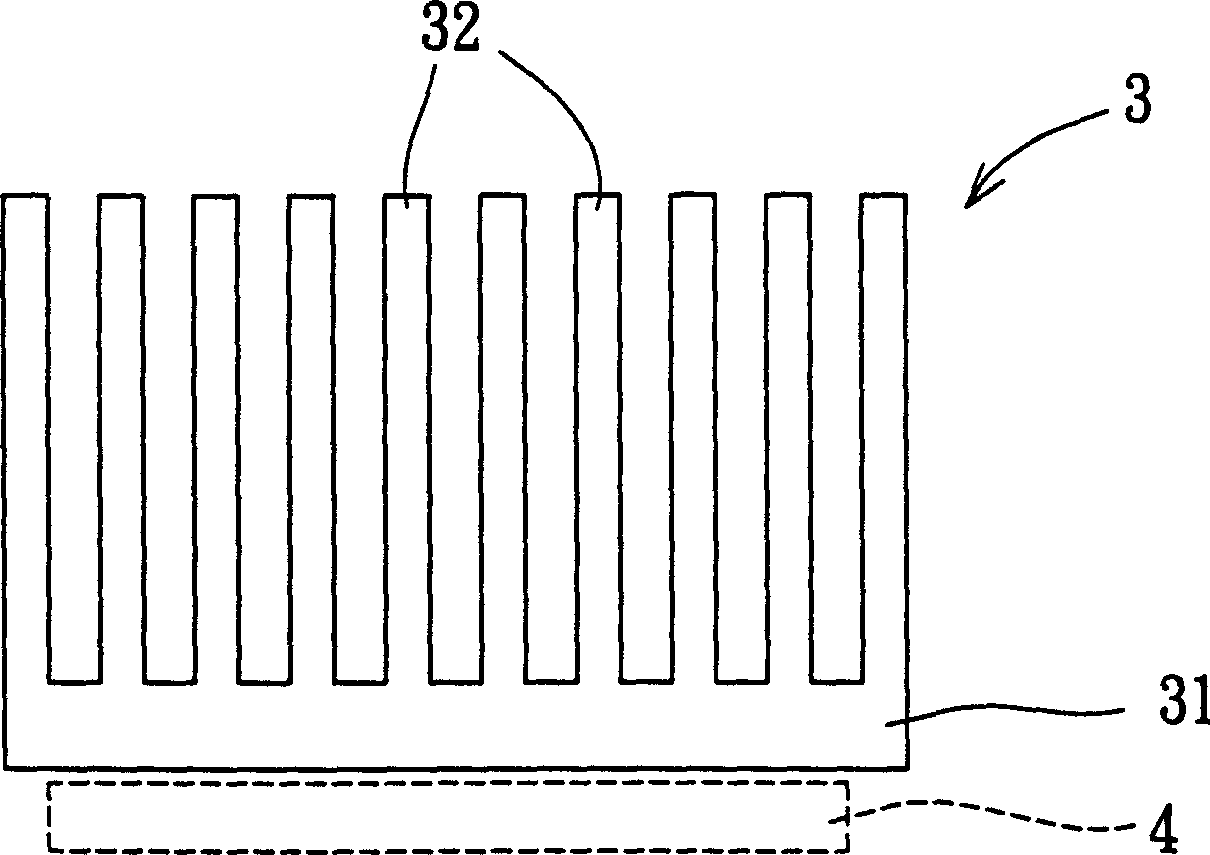

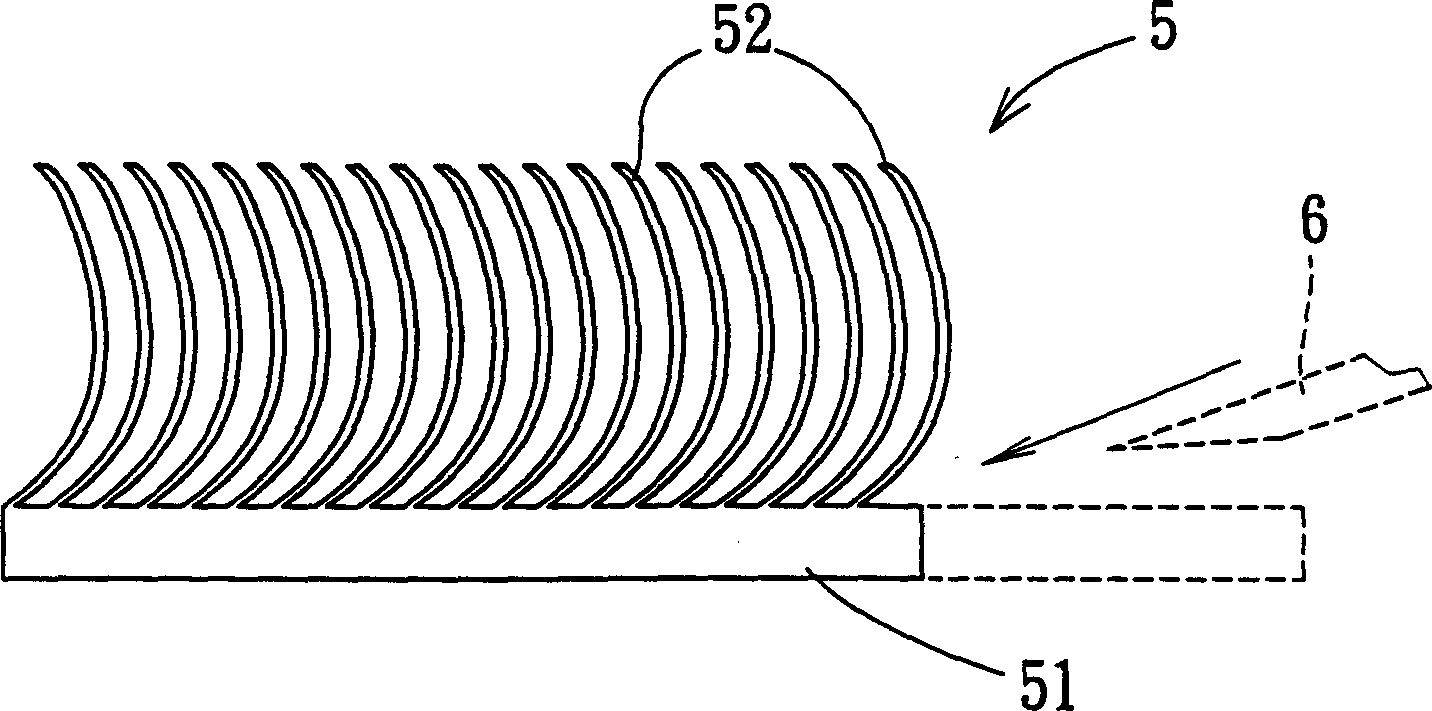

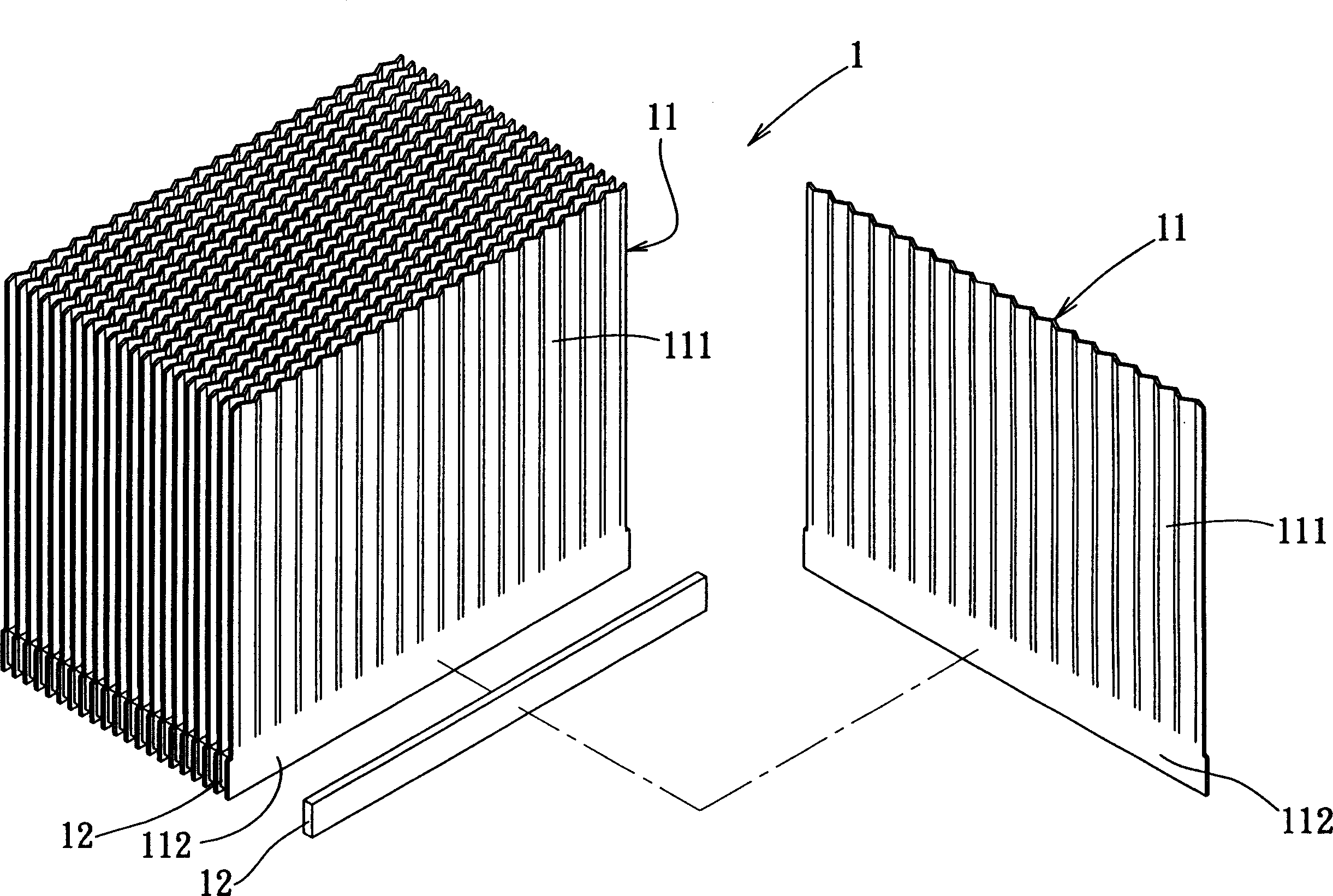

[0036] Refer to image 3 A preferred embodiment of the heat sink 1 of the present invention includes a plurality of fins 11 and a plurality of connecting fins 12.

[0037] Each fin 11 is a sheet-like body with a relatively thin thickness, so that the fins can be divided into a heat dissipation portion 111 and a joint portion 112 connected to each other. In this example, the heat dissipation portion 111 is further formed in a wave shape, thereby improving the contact with the air. The contact area is expected to improve heat dissipation efficiency. Of course, the shape of the heat dissipating portion 111 is not limited to the wave shape. Those skilled in the art can easily produce different shapes to achieve the same effect of increasing the contact area with the air, and no examples are given here.

[0038] The area of each connecting piece 12 is generally slightly smaller than the area of the joint 112 of the fin 11 but has a certain thickness, so that each connecting piece 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com