Output control method of welding source device

A technology for welding power supply and output control, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., and can solve problems such as poor welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

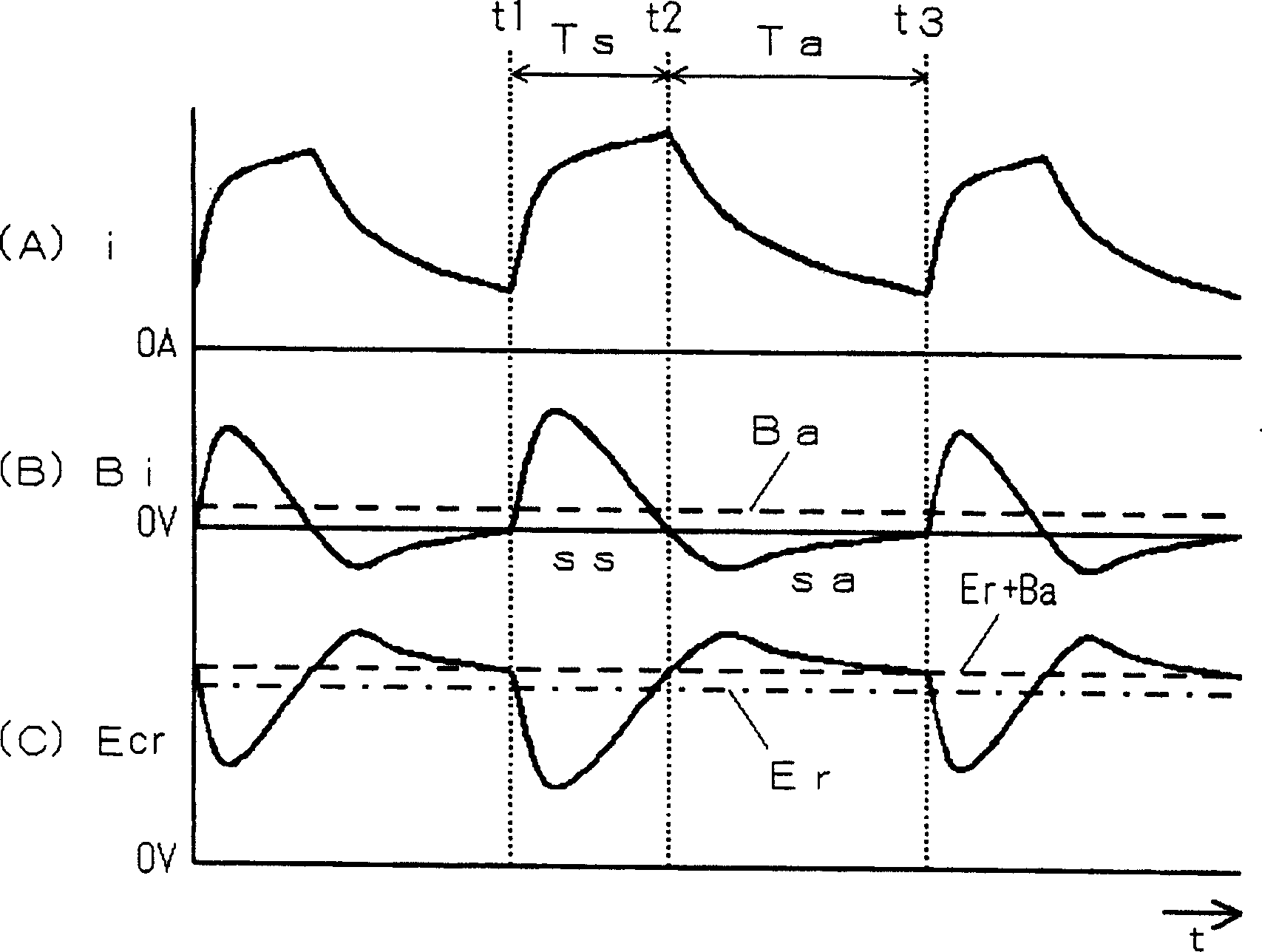

[0059] Embodiment 1 of the present invention is a method of smoothing the current differential signal Bi=Lr·di / dt in conventional electronic reactor control, calculating the current differential smoothing value Ba, and calculating the voltage control setting signal Ecr =Er-Bi+Ba, to control the output voltage. As will be described later, even if the amplification factor Lr changes, the average value of the voltage control setting signal Ecr is kept at a substantially constant value by the current differential smoothing value Ba.

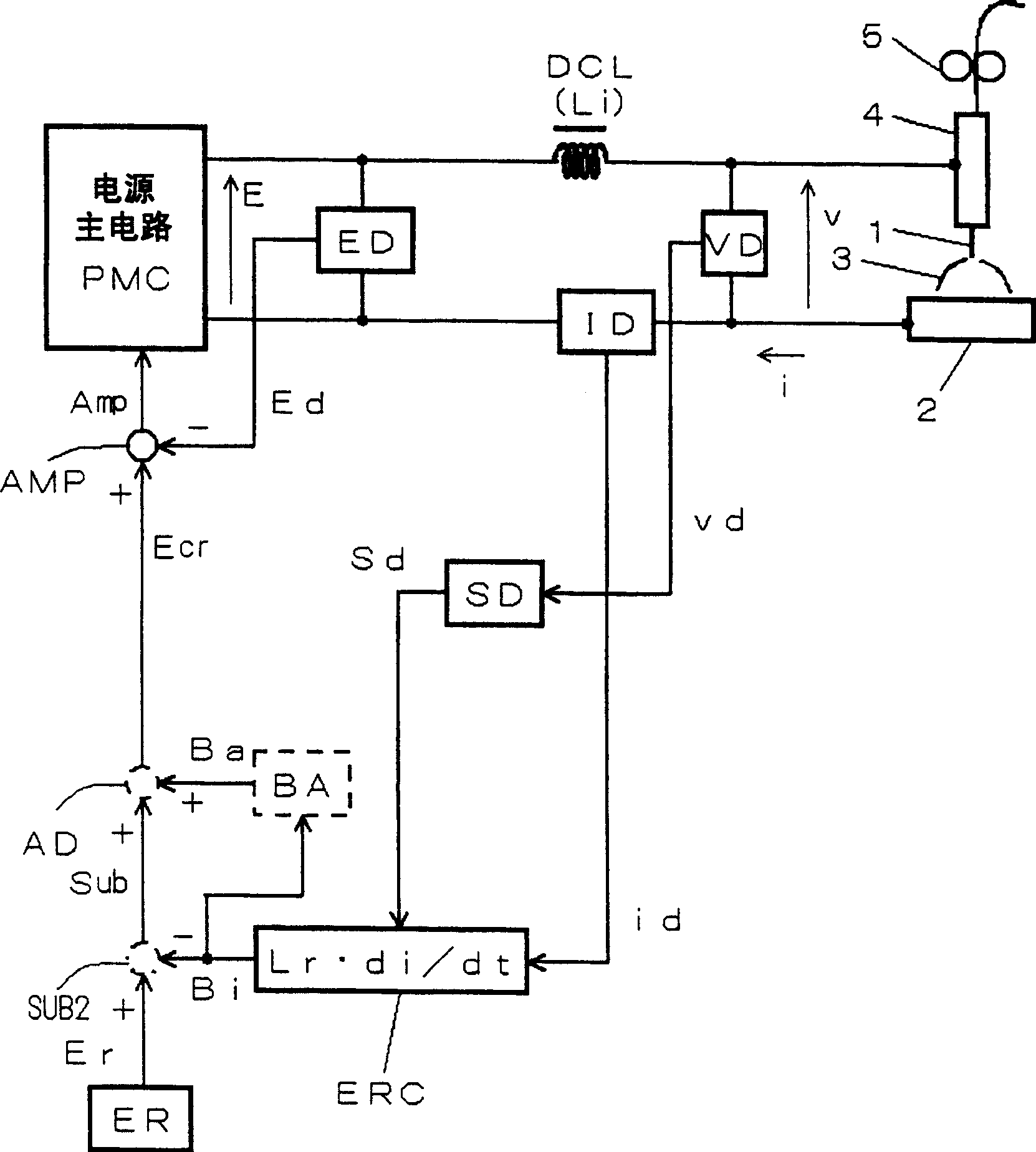

[0060] figure 1 It is a block diagram of the welding power source device concerning Embodiment 1.

[0061] figure 1 This is the scheme: in Figure 6 In the above, an addition circuit AD is added between the subtraction circuit SUB and the error amplifier circuit AMP, and a current differential smoothing circuit BA is added between the addition circuit AD and the electronic reactor control circuit ERC. Moreover, in figure 1 in, will Figure 6 T...

Embodiment approach 2

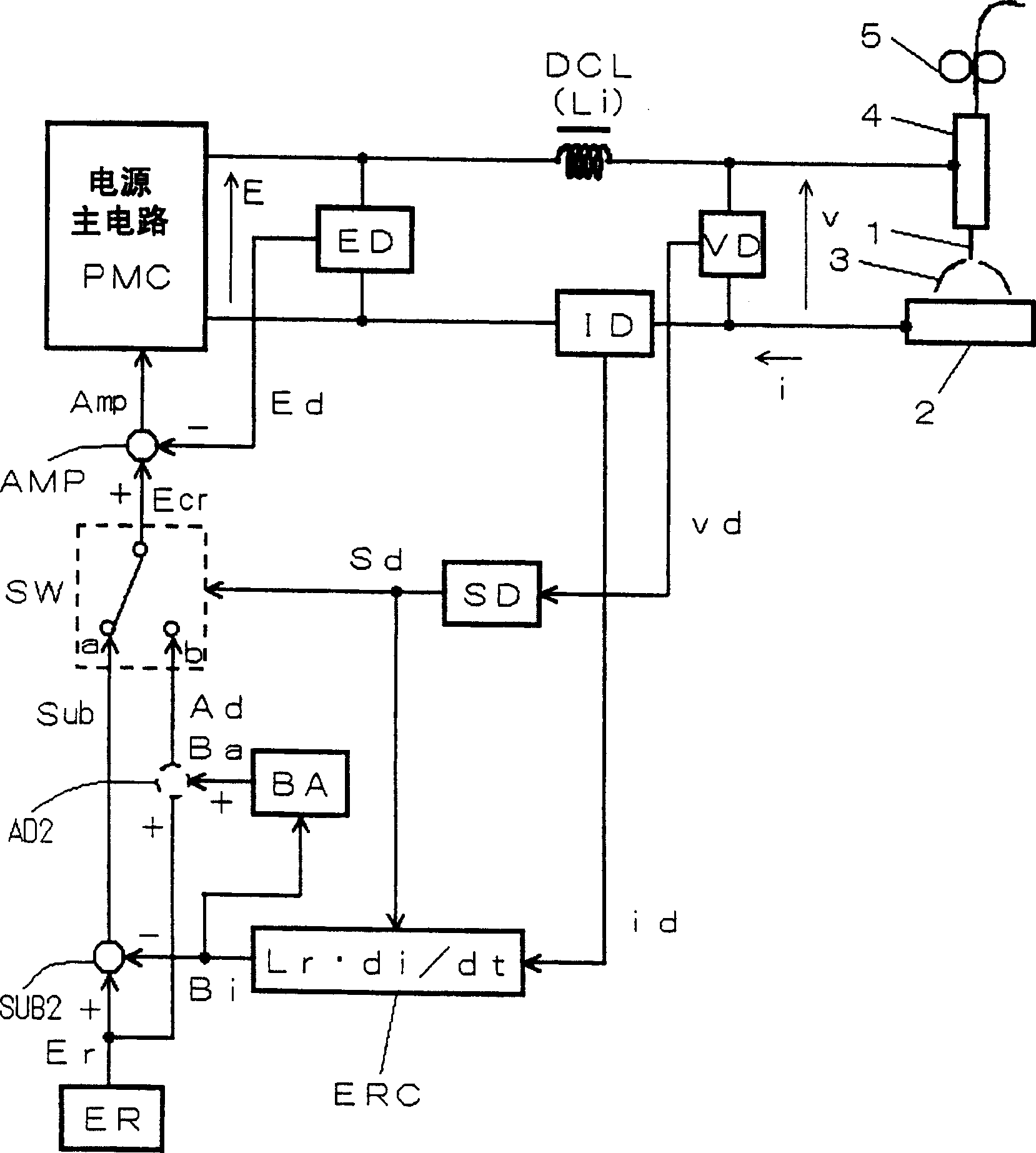

[0066] Embodiment 2 of the present invention is a method of smoothing the current differential value Bi=Lr·di / dt in the above-mentioned Embodiment 1, calculating the smoothed current differential value Ba, and controlling the voltage setting signal during the short-circuit period. Ecr is calculated as the value Ecr=Er-Bi subtracting the current differential value Bi from the output voltage set value Er, and during the arc period, the voltage control setting signal Ecr is calculated as the output voltage set value Er plus the current differential smoothing value The value of Ba is Ecr=Er+Ba. As described above, in general, the amplification factor Lr is set to a large value during the short-circuit period, and the amplification factor Lr is set to a small value during the arc period. In this case, since it is equivalent to the result of subtracting the current differential value Bi only during the short-circuit period, by adding the smoothed current differential value Ba only d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com